A method for co-producing sulfur-based compound fertilizer with sulfur-based nitrogen and potassium fertilizer

A technology of sulfur-based compound fertilizer and sulfur-based nitrogen, which is applied in urea compound fertilizer, potash fertilizer, nitrogen fertilizer and other directions, can solve the problems of complex technological process, and achieve the effects of low energy and material consumption, convenient transportation and high reaction rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

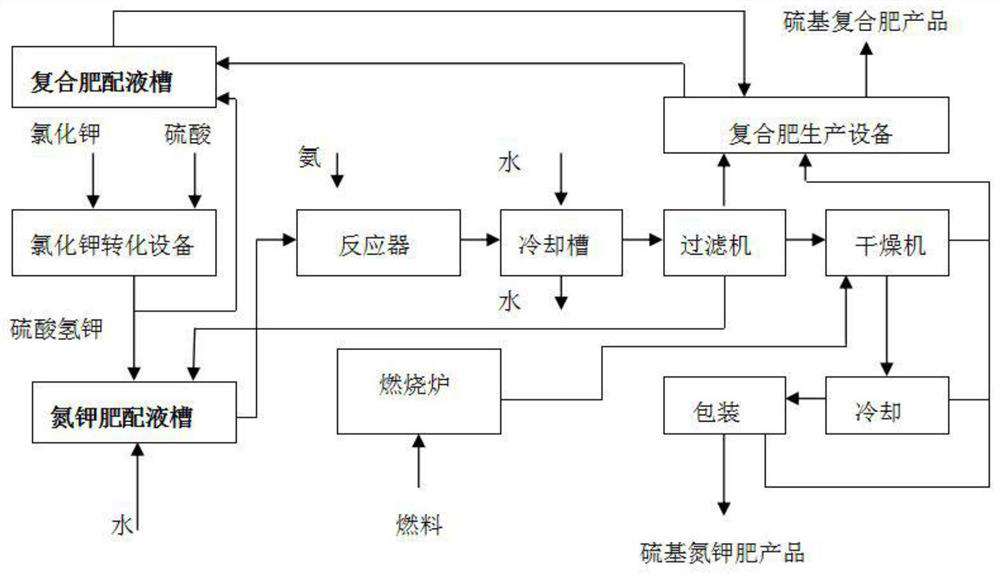

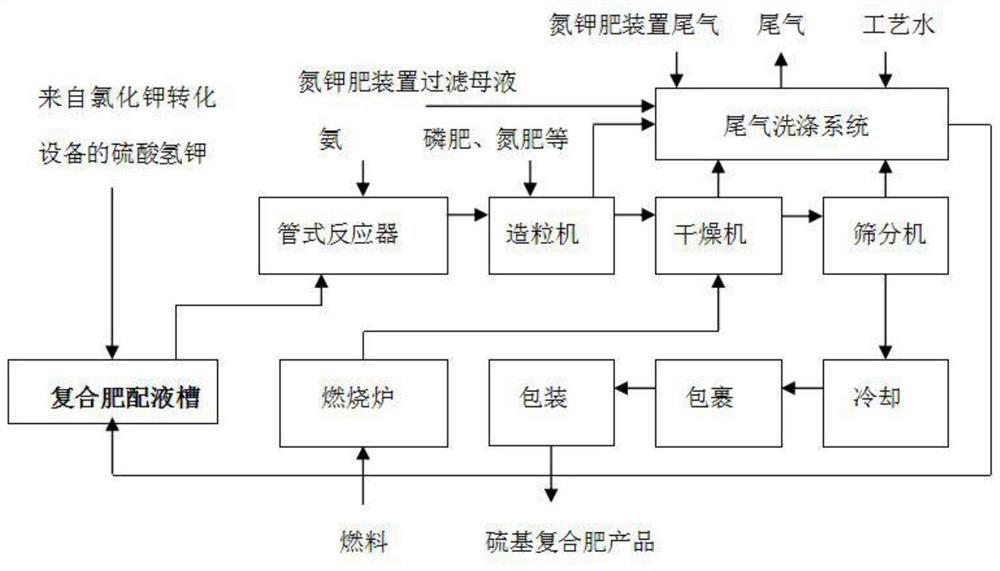

Method used

Image

Examples

Embodiment 1

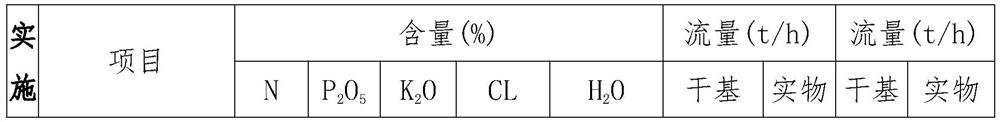

[0047] Example 1 - "7-0-33" sulfur-based nitrogen and potassium fertilizer co-production of "15-15-15" sulfur-based compound fertilizer

[0048] Raw material: Potassium chloride: K 2 O=60%, water content=1%; sulfuric acid: H 2 SO 4 = 98%, H 2 O=2%; synthetic ammonia: NH 3 =99.5%, H 2 O=0.5%; Monoammonium Phosphate: N=11%, P 2 o 5 = 44%, H 2 O=2%; DAP: N=18%, P 2 o 5 = 46%, H 2 O=2%; Urea: N=46.0%, H 2 O=1%.

[0049] 1. In the potassium chloride conversion equipment, put potassium chloride at a flow rate of 20.00t / h and sulfuric acid at a flow rate of 23.84t / h, the reaction temperature is 110°C-130°C, and when the conversion rate reaches 85%, the output Contains K 2 O%=34.02, Cl%=3.84 molten state potassium bisulfate material A=35.27t / h (dry basis), output HCl=7.90t / h (dry basis) simultaneously, absorb HCl by-product hydrochloric acid with water or be used for Manufacture of other chlorine-containing products.

[0050] 2. A part of the molten state potassium bisu...

Embodiment 2

[0068] Example 2——“5-0-36” sulfur-based nitrogen and potassium fertilizer co-production of “17-14-10” sulfur-based compound fertilizer

[0069] Raw material: Potassium chloride: K 2 O=60%, water content=1%; sulfuric acid: H 2 SO 4 = 98%, H 2 O=2%; synthetic ammonia: NH 3 =99.5%, H 2 O=0.5%; Monoammonium Phosphate: N=11%, P 2 o 5 = 44%, H 2 O=2%; DAP: N=18%, P 2 o 5 = 46%, H 2 O=2%; Ammonium Nitrate: N=32%, P 2 o 5 = 4%, H 2 O=1%.

[0070] 1. In the potassium chloride conversion equipment, put potassium chloride at a flow rate of 20.00t / h and sulfuric acid at a flow rate of 23.84t / h, the reaction temperature is 110°C-130°C, and when the conversion rate reaches 85%, the output Contains K 2 O%=34.02, Cl%=3.84 molten state potassium bisulfate material A=35.27t / h (dry basis), output HCl=7.90t / h (dry basis) simultaneously, absorb HCl by-product hydrochloric acid with water or be used for Manufacture of other chlorine-containing products.

[0071] 2. A part of the mo...

Embodiment 3

[0089] Example 3 - "4-0-40" sulfur-based nitrogen and potassium fertilizer co-production "16-15-14" sulfur-based compound fertilizer

[0090] Raw material: Potassium chloride: K 2 O=60%, water content=1%; sulfuric acid: H 2 SO 4 = 98%, H 2 O=2%; synthetic ammonia: NH 3 =99.5%, H 2 O=0.5%; DAP: N=18%, P 2 o 5 = 46%, H 2 O=2%; Urea: N=46%, H2O=1%.

[0091] 1. In the potassium chloride conversion equipment, put potassium chloride at a flow rate of 20.00t / h and sulfuric acid at a flow rate of 23.84t / h, the reaction temperature is 110°C-130°C, and when the conversion rate reaches 85%, the output Contains K 2 O%=34.02, Cl%=3.84 molten state potassium bisulfate material A=35.27t / h (dry basis), output HCl=7.90t / h (dry basis) simultaneously, absorb HCl by-product hydrochloric acid with water or be used for Manufacture of other chlorine-containing products.

[0092] 2. A part of the molten state potassium bisulfate material A1 is added to the liquid distribution tank of the n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com