A method for mass production of low-iron quartz dry sand

A technology of iron quartz and dry sand, applied in chemical instruments and methods, wet separation, silicon dioxide, etc., can solve the problems of inability to meet the requirements of the times, large market gap, low output of low iron quartz sand, etc. The effect of selecting job productivity, improving product quality, and high job productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

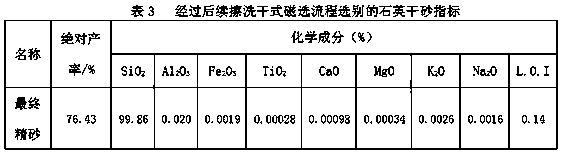

[0029] Taking vein quartz ore as an example, the typical indicators of the mined ore ore are shown in Table 1.

[0030]

[0031] It can be seen from the data in Table 1 that the raw ore was crushed to prepare the sample SiO 2 =99.38%~99.55%, after the sample is manually magnetically separated, Fe 2 o 3 =0.024%~0.044%, which is far from meeting the requirements of optical glass, crystal ornaments and electronic grade silica powder.

[0032] The raw ore of the above-mentioned vein quartz ore undergoes the conventional mineral processing process, that is, the flotation concentrate index after the process of "three-stage crushing-grinding-blocking-medium magnetic-strong magnetic-grading-flotation" process is listed in Table 2

[0033]

[0034] From the data in Table 2, it can be known that the above-mentioned raw ore is separated by the conventional mineral processing process of "three-stage crushing-grinding-blocking-medium magnetic-strong magnetic-classification-flotatio...

Embodiment 2

[0036] A method for mass producing low-iron quartz dry sand, which also uses the above-mentioned vein quartz mineral as a selected raw material, is characterized in that it includes the following steps:

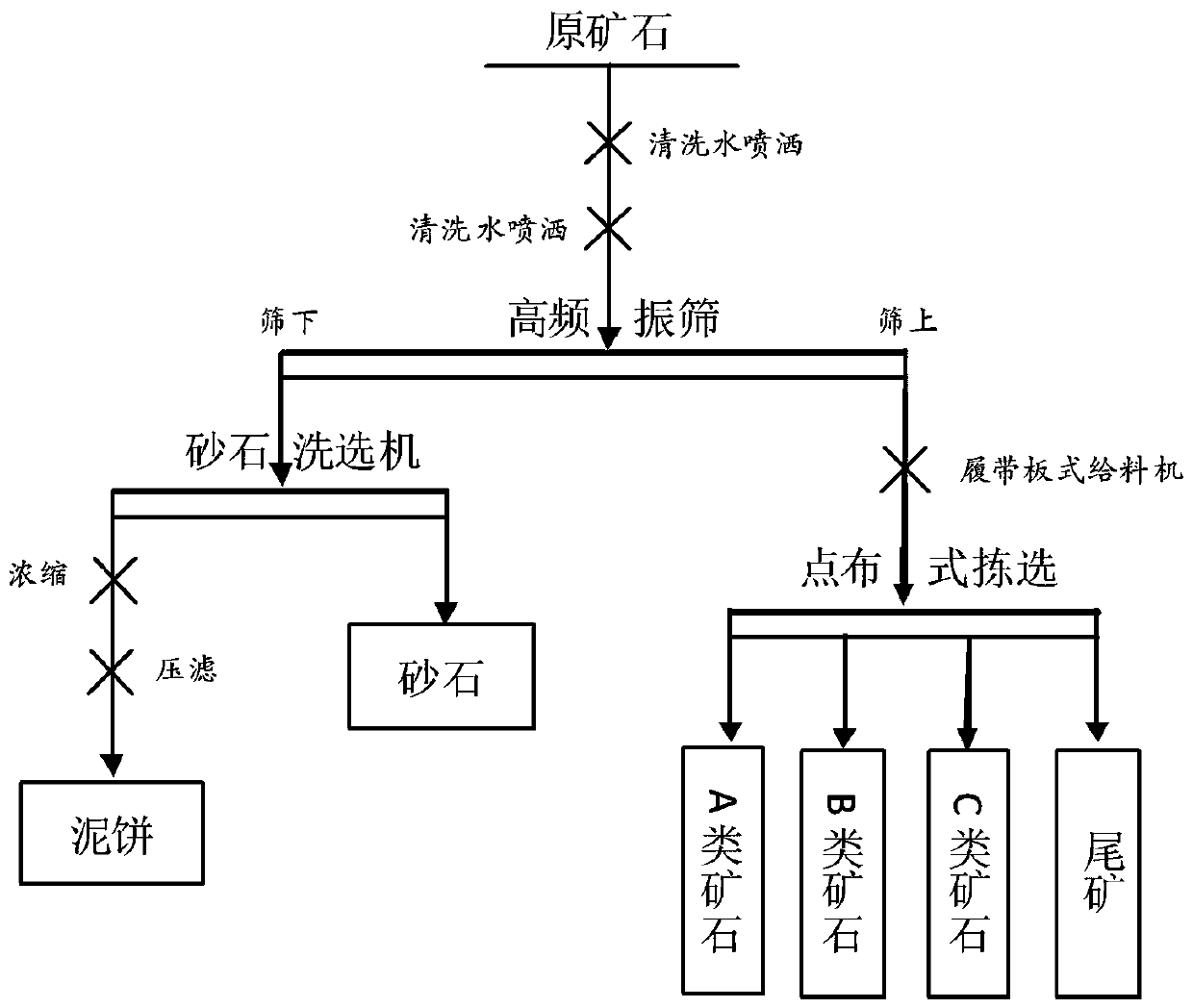

[0037] 1). If figure 1 As shown, the crawler point distribution manual sorting system adopted is to feed the material to the high-frequency vibrating screen through the loader, clean the surface of the ore with an appropriate amount of water, remove the mud, and then distribute the material evenly through the crawler plate feeder. Sorting workers with different responsibilities are assigned to the side, and the tailings, C-type ore, B-type ore and A-type ore are sorted out in turn, and are used for external sales and raw materials for the production of low-iron sand with different specifications of 60ppm, 30ppm, and 20ppm, so as to realize the ore. Precise sorting.

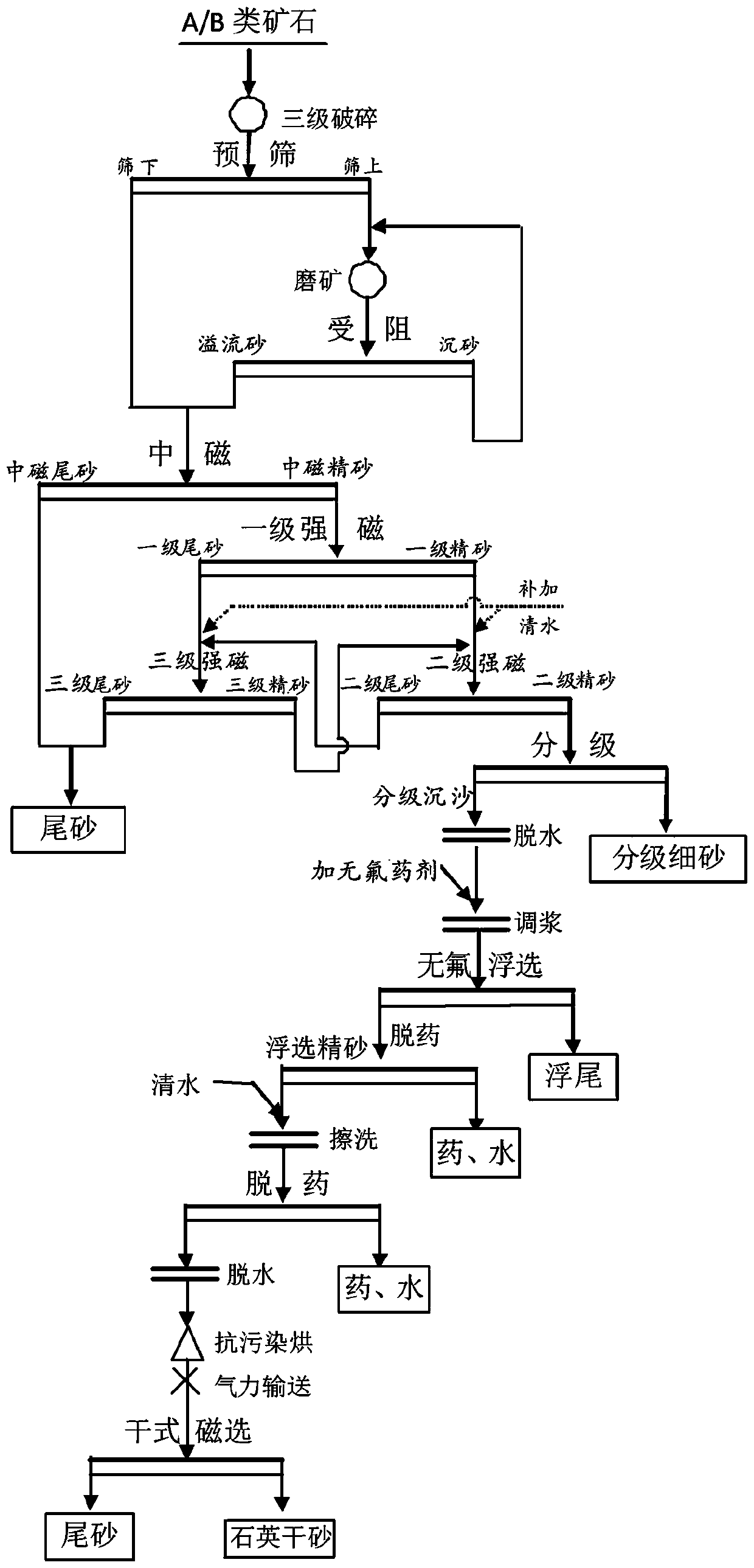

[0038] 2). If figure 2As shown, the sorted A and B ores are subjected to three-stage crushing, ore grinding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com