A fully inorganic perovskite solar cell and a preparation method thereof

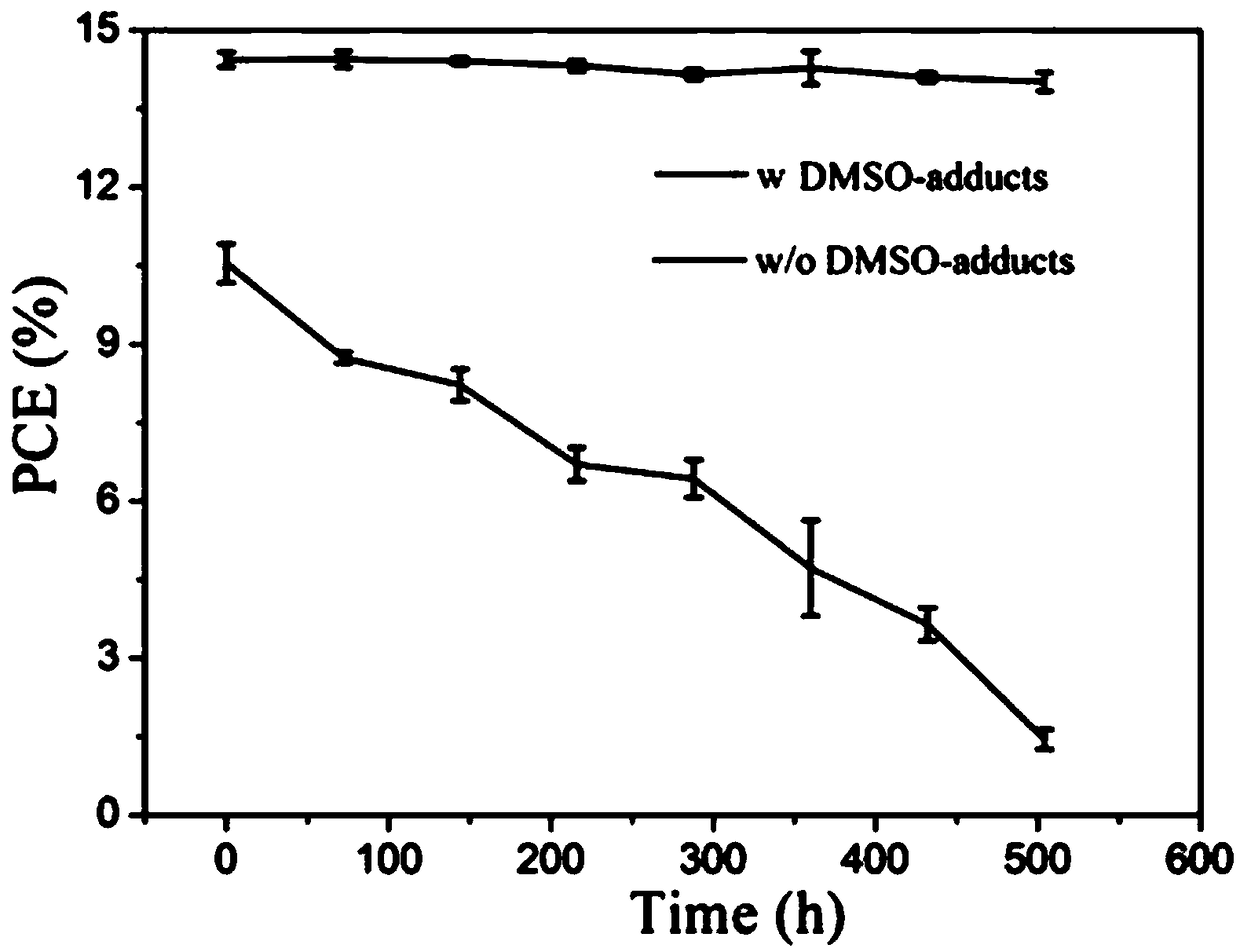

A technology for solar cells and inorganic calcium, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as low solubility, limited device performance, and poor film-forming properties of inorganic perovskite, so as to improve solubility and film-forming quality , solve the effect of low solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

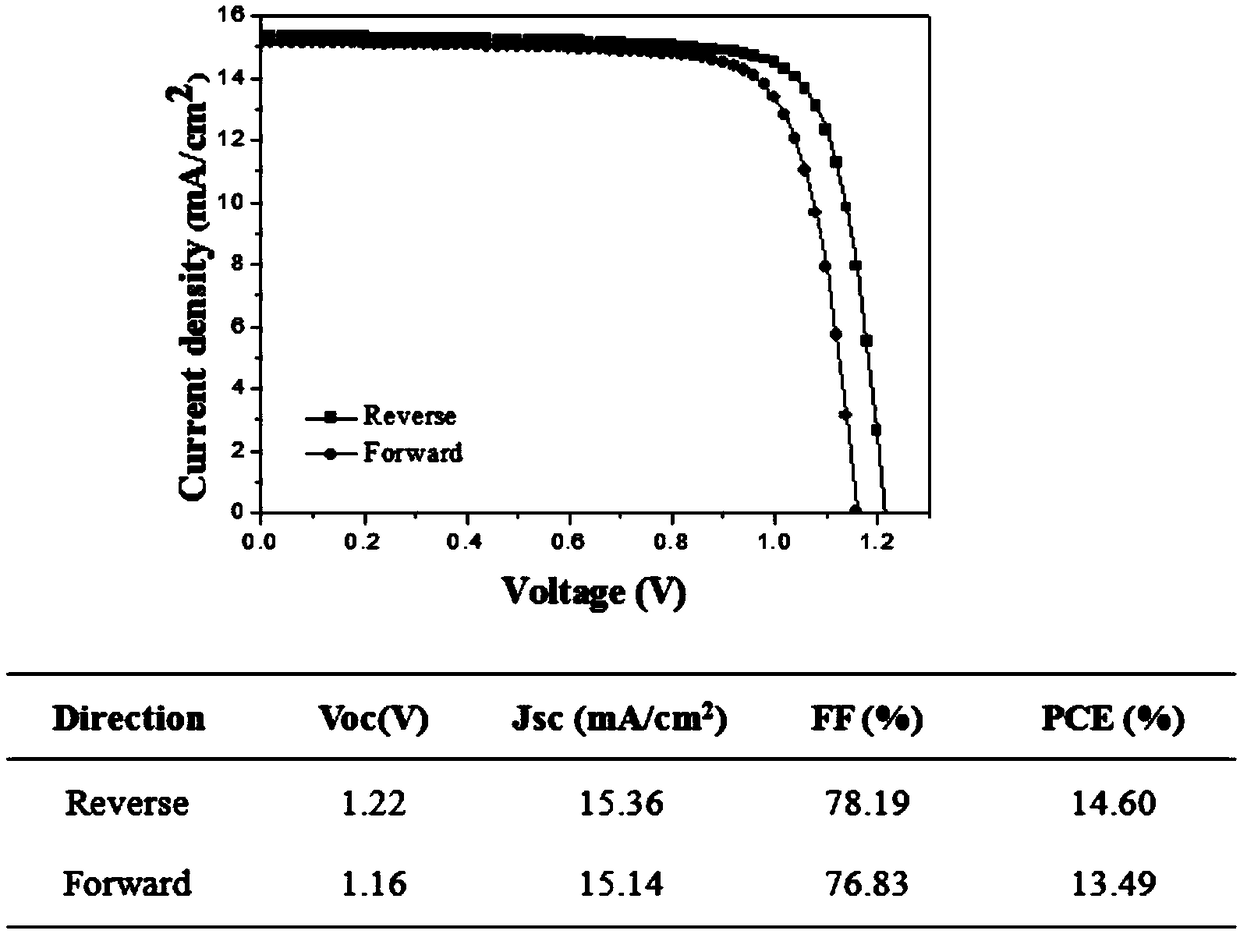

Embodiment 1

[0028] First, the complex PbI 2 (DMSO) preparation: 4.84g PbI 2 Dissolve in 15mL DMSO, heat to PbI at 60°C 2 Dissolve completely, and then slowly add about 35mL of toluene to it, and a white precipitate appears. After the precipitate is completely precipitated, the precipitate is filtered, left at room temperature for 3 hours, and then vacuum-dried at 60°C for 24 hours.

[0029] Second, the complex PbBr 2 (DMSO) preparation: 3.85g PbBr 2 Dissolve in 15mL DMSO, heat to PbBr at 60°C 2 Dissolve completely, and then slowly add about 35mL of hot acetone to it, and a white precipitate appears. After the precipitate is completely precipitated, filter the precipitate, leave it at room temperature for 3 hours, and then dry it under vacuum at 60°C for 24 hours.

[0030] Third, refine CsI grains: Dissolve 2.73g CsI in 15mL DMSO, slowly raise the temperature until CsI is completely dissolved, then slowly add about 35mL isopropanol to it, a white precipitate appears, and after the prec...

Embodiment 2

[0038] In this example, the thickness of the gold electrode is 90nm, and the annealing process for crystallizing the precursor thin film to form an all-inorganic perovskite light absorbing layer is: 30°C, 5min, 120°C, 2min. Other steps are identical with embodiment 1. In this example, the efficiency of the inorganic perovskite solar cell was 13.48%.

Embodiment 3

[0040] In this example, the thickness of the gold electrode is 85nm, and the preparation of CsPbI 2 The solvent used for the Br precursor solution is DMF. Other steps are identical with embodiment 1. In this example, the efficiency of the inorganic perovskite solar cell was 10.08%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com