A preparation method of carburizing strengthened biomimetic structure based on pulsed arc

A pulsed arc and carburizing technology, which is applied in the field of carburizing and strengthening the bionic structure, can solve the problems of uncontrollable scale shape, unsuitable for promotion and use, expensive equipment, etc., to achieve improved viscosity reduction, improved wear resistance, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: Taking pulse arc carburizing as an example to strengthen the scaly bionic structure, the process includes the following steps:

[0030] The welding machine model used in this example is YJHB-2 precision welding machine, purchased from Yijing Electronics Co., Ltd., and the purchased graphite electrode specification is R 0 (1mm)×L 0 (300mm), purchased from Shenzhen Baide Hardware Machinery Co., Ltd.

[0031] (1) Grinding, polishing and cleaning the surface of the alloy sample (45# steel sample) with a surface size of 40*40mm to remove impurities such as oil stains and oxide layers on the surface of the alloy sample. The specific steps are: first use a grinding machine Remove the oxide layer and sand grains on the surface of the alloy sample (45# steel sample), and then use a non-woven cloth dipped in thinner to clean the oil and other impurities on the surface of the sample (45# steel sample); , sandpaper and polishing cloth etc. are all prior art, can direct...

Embodiment 2

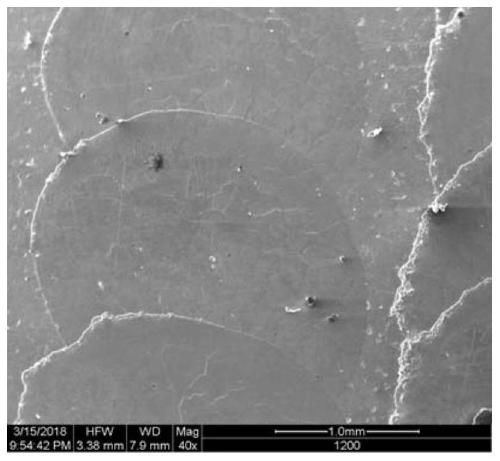

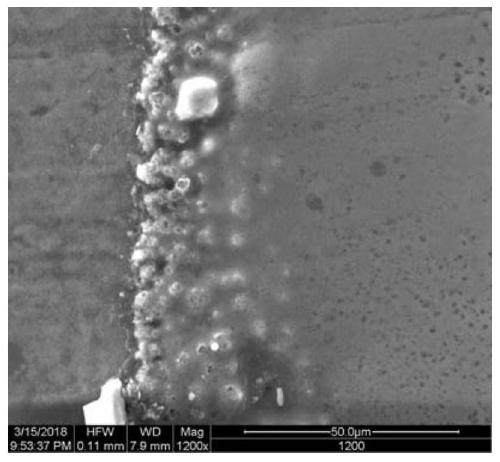

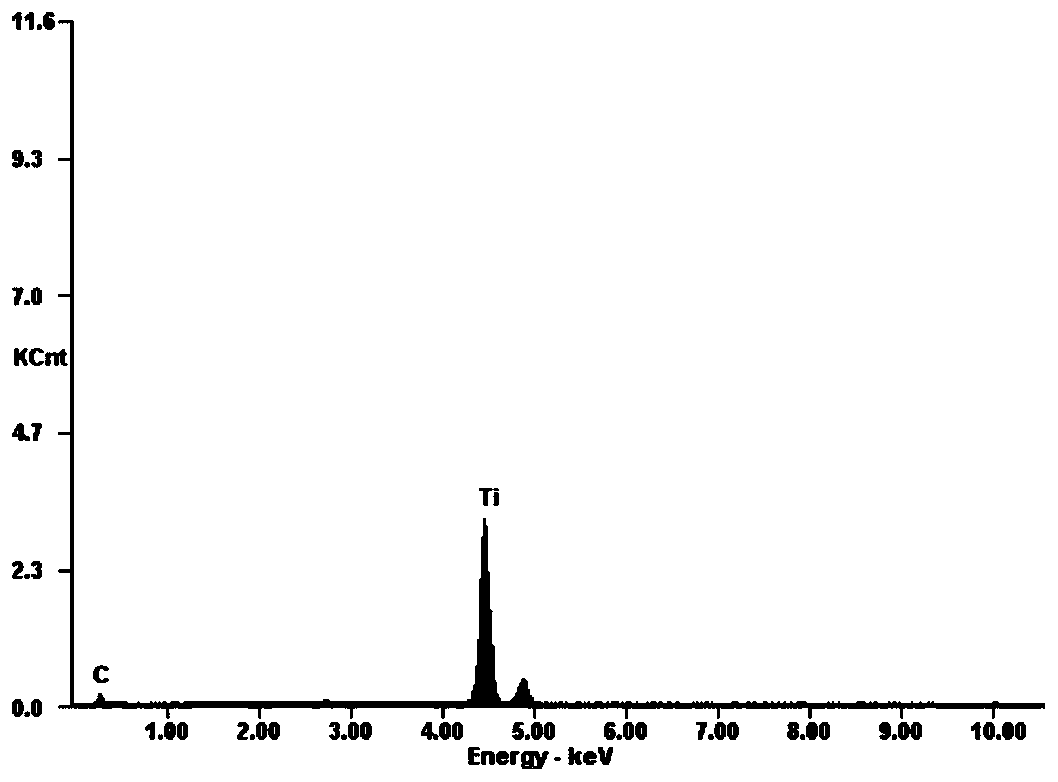

[0047] According to the steps described in Example 1, an overlapping scale-like bionic structure is prepared on the surface of the titanium metal sample, wherein the pulse current is 70A, the pulse time is 40ms, the diameter of the graphite electrode is 1.2mm, and the distance between the graphite electrode and the surface of the titanium metal sample Controlled at 0.5mm, the overlapping part of the scale-like bionic structures does not exceed half the diameter of the molten pool. Scanning electron microscopy was used to observe the surface morphology of titanium metal samples, such as figure 1 As shown, the surface composition of the titanium metal sample obtained by X-ray energy spectroscopy is as follows: image 3 as shown, image 3 The surface composition data of titanium metal samples in Table 4. Depend on figure 1 It can be seen that the structure generated by the pulse is circular, and the scale-like biomimetic structure is obtained by stacking the circular spots. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com