A kind of flame retardant and preparation method thereof, polycarbonate composite material and preparation method thereof

A polycarbonate and composite material technology, which is applied in the preparation of sulfonic acid amides, organic chemistry, etc., can solve the problems of poor water resistance of sulfonate flame retardants, great influence on the performance of PC materials, and high cost of silicon-based flame retardants. The effect of promoting PC cross-linking, small influence on mechanical properties, and high content of flame retardant elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The present invention also provides a preparation method of flame retardant, comprising the following steps:

[0048] The 1,3,5,7-p-tetraphenylsulfonyl chloride adamantane is first reacted with ammonia water to obtain 1,3,5,7-p-tetraphenylsulfonamide adamantane;

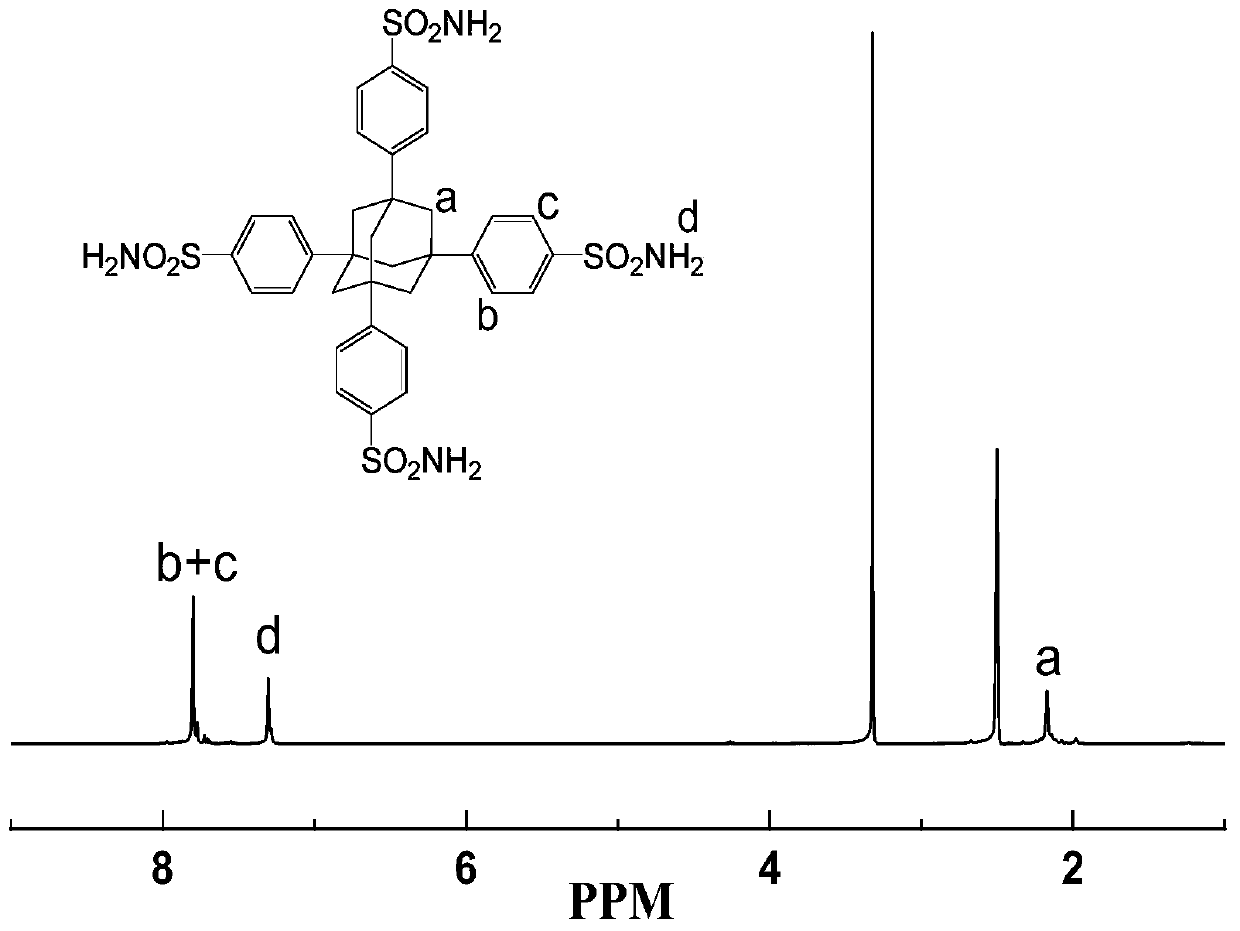

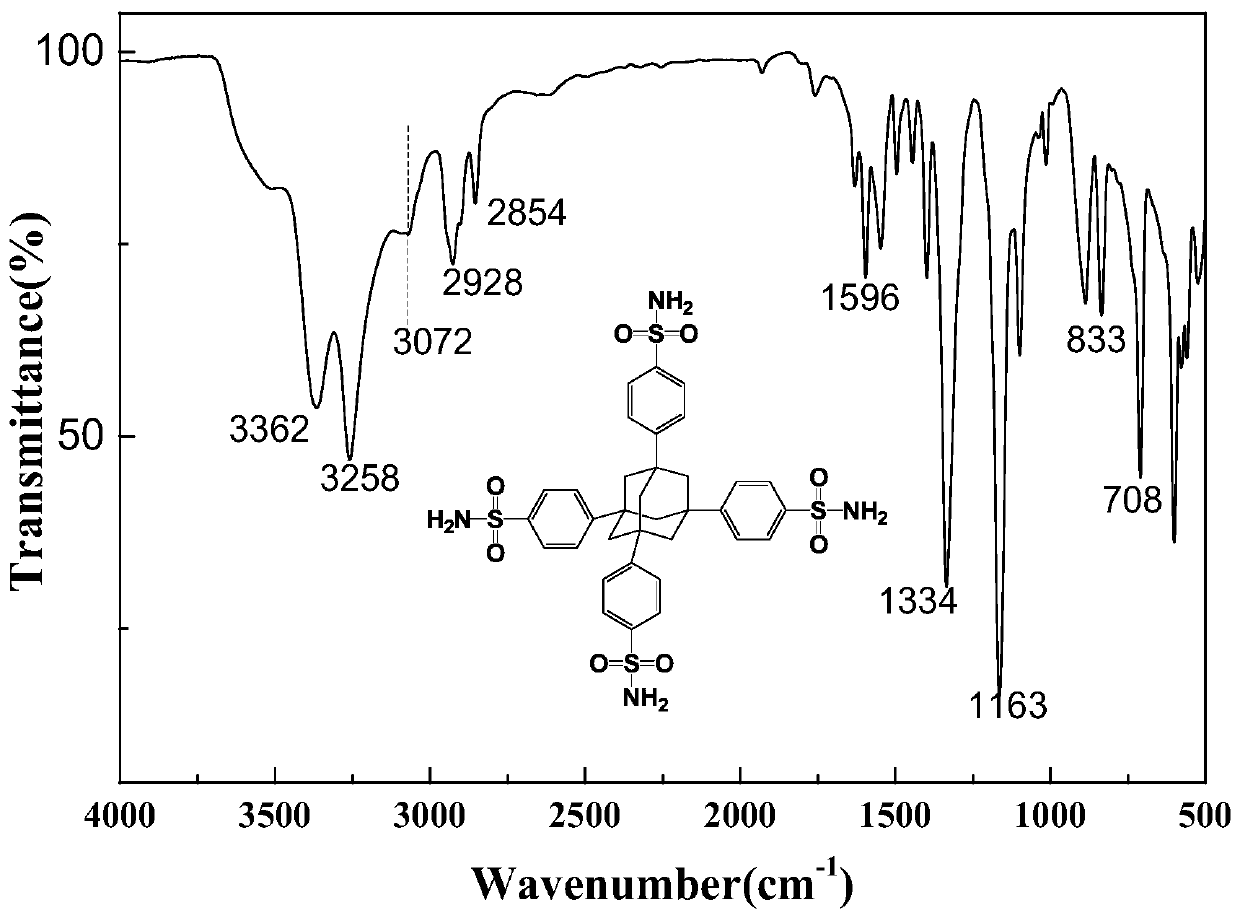

[0049] Wherein, the structural formula of 1,3,5,7-tetraphenylsulfonamide adamantane is as shown in formula (I);

[0050]

[0051] In the present invention, the first reaction of 1,3,5,7-p-tetraphenylsulfonylchloroadamantane and ammonia specifically includes:

[0052] After dissolving 1,3,5,7-p-tetraphenylsulfonyl chloride adamantane in the first organic solvent, ammonia water is added, and the first reaction is carried out under stirring.

[0053] The mass ratio of 1,3,5,7-p-tetraphenylsulfonylchloroadamantane to ammonia water is 1:10-100, preferably 1:10-70, more preferably 1:10-50.

[0054] The mass ratio of 1,3,5,7-p-tetraphenylsulfonylchloroadamantane, the first organic solvent and ammonia water is 1:...

Embodiment 1

[0093] 1) Place 20 g (0.093 mol) of dry 1-bromoadamantane in a condensing reflux device and CaCl 2 In the 500mL three-necked flask of the drying tube, add 100mL (1.12mol) benzene and 26g (95mmol) tert-butyl bromide in sequence, slowly add 2.4g (9.04mmol) anhydrous aluminum trichloride under slow stirring, and heat up to 70°C , maintain a state of intense reflux, carry out Friedel-Crafts alkylation reaction, stop the reaction after 30 minutes of reaction, pour the mixture into an appropriate amount of ice-water mixture, then add an appropriate amount of ether, stir thoroughly, filter, and dry the obtained filter residue at 75°C for 12 hours , and then use chloroform as a solvent for Soxhlet extraction, and after one day of extraction, place the remaining solid at room temperature to dry to obtain a white powder, that is, 1,3,5,7-p-tetraphenyladamantane.

[0094] 2) Add 50mL (0.39mol) of dichloromethane to the 2 In a 150mL three-necked flask with a drying tube, 3.26g (7.41mmol)...

Embodiment 2

[0097] 1) Place 20 g (0.093 mol) of dry 1-bromoadamantane in a condensing reflux device and CaCl 2 In the 500mL three-necked flask of the drying tube, add 150mL (1.12mol) benzene and 26g (95mmol) tert-butyl bromide in sequence, slowly add 2.4g (9.04mmol) anhydrous aluminum trichloride under slow stirring, and heat up to 90°C , maintain a state of intense reflux, carry out Friedel-Crafts alkylation reaction, stop the reaction after 30 minutes of reaction, pour the mixture into an appropriate amount of ice-water mixture, then add an appropriate amount of ether, stir thoroughly, filter, and dry the obtained filter residue at 75°C for 12 hours , and then use chloroform as a solvent for Soxhlet extraction, and after one day of extraction, place the remaining solid at room temperature to dry to obtain a white powder, that is, 1,3,5,7-p-tetraphenyladamantane.

[0098] 2) Same as step 2) of Example 1.

[0099] 3) Same as step 3) of embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com