Low-temperature SCR flue gas denitrification catalyst and preparation method and application thereof

A denitration catalyst, catalyst technology, applied in chemical instruments and methods, heterogeneous catalyst chemical elements, physical/chemical process catalysts, etc., can solve the problems of narrow activity window, high onset temperature, low temperature denitration efficiency, etc. The effect of inhibiting hydrolysis, improving the degree of dispersion, and good NOx removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

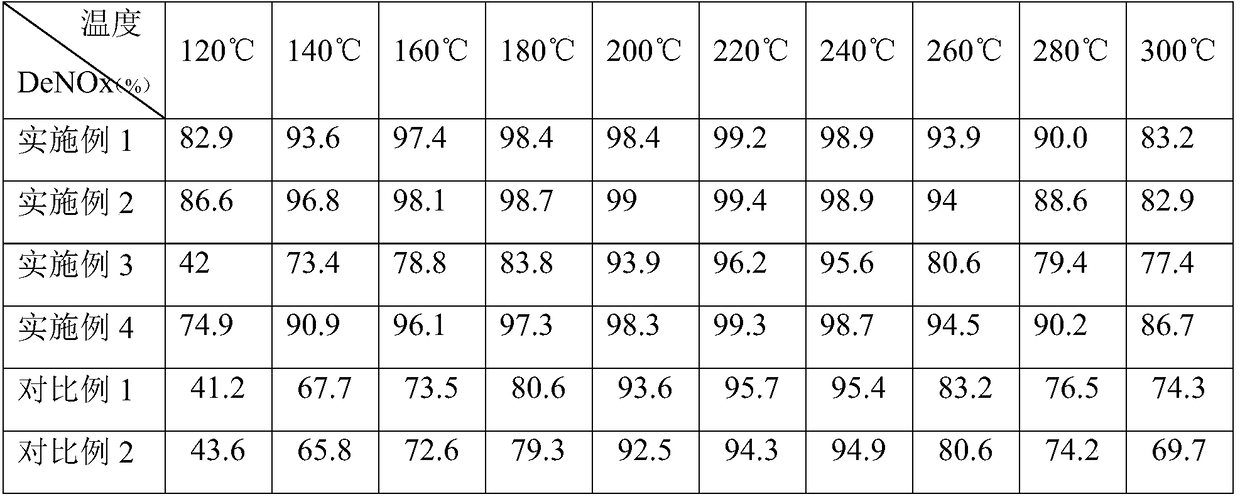

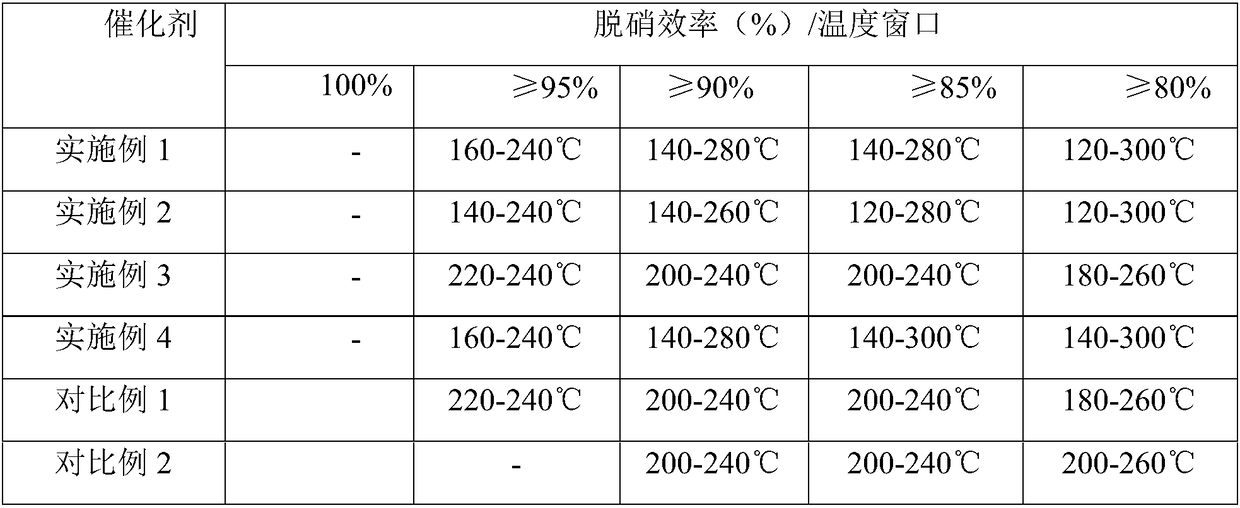

Examples

preparation example Construction

[0025] Another aspect of the present invention provides a method for preparing a low-temperature SCR flue gas denitrification catalyst, wherein the method comprises the following steps:

[0026] (1) Mix oxalic acid, manganese salt, iron salt and water;

[0027] (2) dispersing nano-titanium dioxide in the metal oxalate double salt precursor solution mixed in step (1) and carrying out wet impregnation;

[0028] (3) Calcining the reaction mixture after step (2).

[0029] According to the present invention, based on the total weight of the catalyst, the amount of the carrier can be 85-98% by weight, preferably 90-96% by weight; and in terms of elements, the Fe element in the iron salt and the The molar ratio of the amount of Mn element in the manganese salt can be 1:0.5-2, preferably 1:1-1.5; and the molar ratio of the amount of the iron salt to the oxalic acid is 1:2-4, preferably 1:2.5-3.5, more preferably 1:3.

[0030] According to the present invention, the iron salt can be...

Embodiment 1

[0049] This example is to illustrate the preparation method of the low-temperature SCR flue gas denitrification catalyst provided by the present invention.

[0050] (1) Preparation of the impregnating solution: Weigh the solid oxalic acid and fully dissolve it in deionized water, add the solid ferric nitrate nonahydrate to obtain a yellow-green solution. After fully stirring for 30 minutes, add a manganese nitrate aqueous solution with a concentration of 50% by weight, and fully stir to obtain a clear and transparent dipping solution, wherein, in terms of elements, the Fe element in the iron nitrate nonahydrate and the Mn element in the manganese nitrate The molar ratio of the amount of the iron salt to the oxalic acid is 1:1.5; and the molar ratio of the amount of the iron salt to the oxalic acid is 1:3.

[0051] (2) Dispersion and impregnation of the carrier: add P25 nano-titanium dioxide in the impregnation solution obtained in step (1), wherein, based on the total weight o...

Embodiment 2

[0054] This example is to illustrate the preparation method of the low-temperature SCR flue gas denitrification catalyst provided by the present invention.

[0055] (1) Preparation of the impregnating solution: Weigh the solid oxalic acid and fully dissolve it in deionized water, add the solid ferric nitrate nonahydrate to obtain a yellow-green solution. After fully stirring for 30 minutes, add 50% by weight of manganese nitrate aqueous solution, and fully stir to obtain a clear and transparent impregnation solution, wherein, in terms of elements, the amount of the Fe element in the iron nitrate nonahydrate and the Mn element in the manganese nitrate The molar ratio of the iron salt to the oxalic acid and water is 1:3.

[0056] (2) Dispersion and impregnation of the carrier: add P25 nano-titanium dioxide in the impregnation solution obtained in step (1), wherein, based on the total weight of the catalyst, the amount of the carrier can be 91% by weight, and then Stir and impre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com