A pretreatment method and device for automatic food microbial detection

A microbial detection and food technology, applied in enzymology/microbiology devices, methods of supporting/immobilizing microorganisms, post-processing of biomass, etc., can solve the problems of low detection quantity, reduction of detection microorganisms, inaccurate detection results, etc., to achieve The effect of improving accuracy, avoiding loss of quality and quantity, and increasing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0038] As a specific implementation, the operation process of the culture cup is:

[0039] 1) The sample is put into the culture cup, and the culture cup is rotated at a low speed for mixing;

[0040] 2) After the sample is mixed, the culture platform and the culture cup perform planetary motion, and the sample moves at a non-uniform speed in the culture cup to achieve the effect of extracting bacteria;

[0041] 3) The culture cup rotates again, preferably the rotation time is 15-30 minutes, more preferably 20 minutes. After the autobiography stops, the filter in the culture cup holds up the sample, and the concentration device draws the culture solution to wash the sample under high pressure. The preferred washing time is 1-3 minutes;

[0042] 4) After the filter screen is lowered, sterile air is fed into the concentration device to carry out concentration, and the concentration time is preferably 2 to 10 minutes.

[0043] The method of the present invention is carried out ...

Embodiment 1

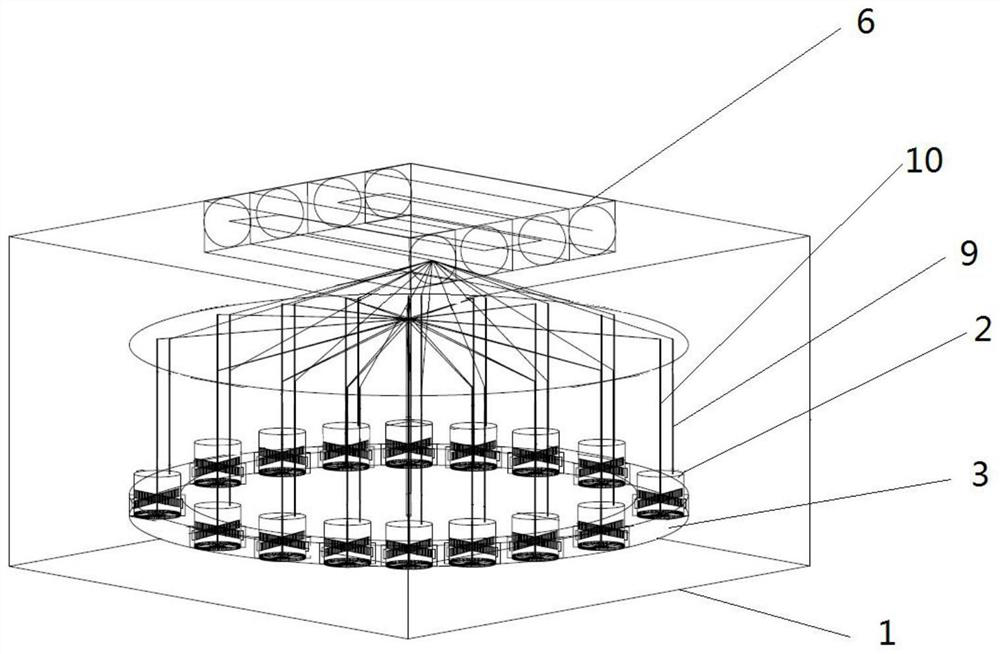

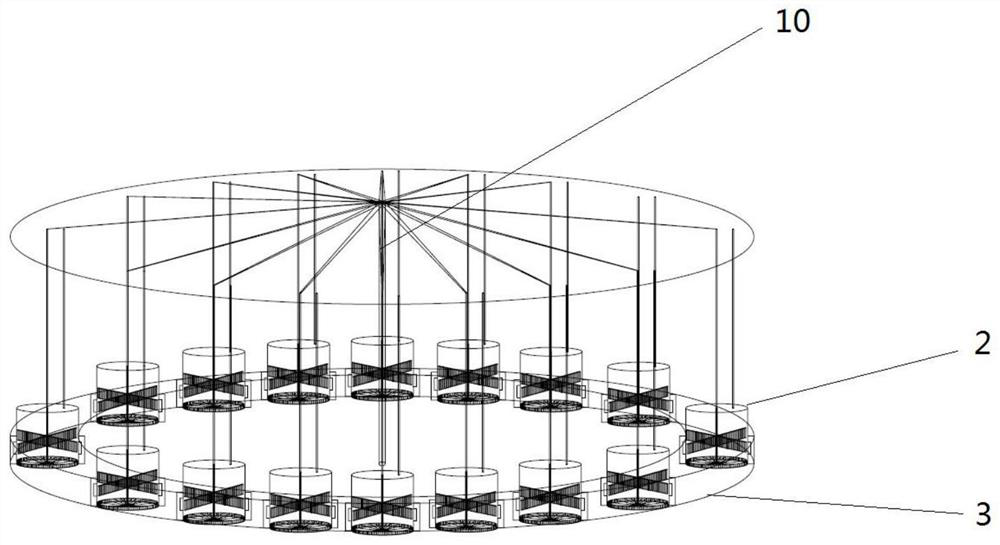

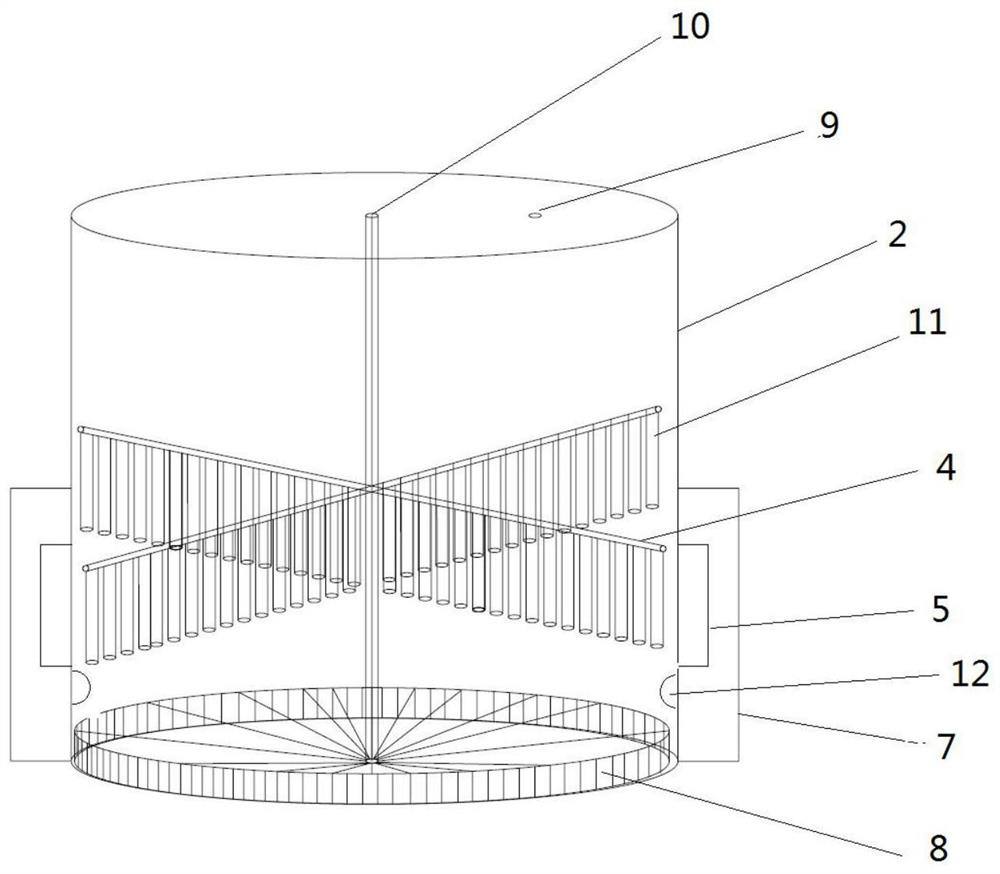

[0059] An automatic pre-processing device for food microbial detection, comprising an airtight body 1, and an airtight independent culture cup 2, a culture platform 3, a concentration device 4, a constant temperature device 5, and a safety enforcement device 6 arranged in the airtight body 1. The cultivation platform 3 can rotate horizontally relative to the airtight main body 1, and several cultivation cups 2 fixing devices 7 are arranged around the cultivation platform 3, which are used to fix the cultivation cups 2 on the cultivation platform 3, and can be operated along with the cultivation platform 3. Planetary movement. The culture cup 2 is fixed in the fixing device 7 on the culture platform 3, and the horizontal rotation of the culture cup 2 can be realized. There are protrusions 12 on the inner wall of the culture cup 2, and the culture solution is pre-embedded in the culture cup 2. After the sample is put into the culture cup 2, the culture cup 2 is closed to form an...

Embodiment 2

[0061] Put 25g of oatmeal into the culture cup pre-filled with agar medium, add 225ml of sterile water to the mark, put it into the corresponding fixture of the culture platform, and close the hatch. The air path of the rotor is automatically docked, sterile air is introduced, the temperature of the constant temperature device is controlled to 37°C, the culture cup rotates at a low speed of 100rpm, and the sample medium is mixed evenly. The culture platform performs non-uniform planetary motion in the culture cup, the minimum speed is 100rpm, and the maximum speed is 220rpm. After the concentration device is fed with sterile air for 10 minutes, control the temperature of the constant temperature device to 45°C for 10 minutes, the filter in the culture cup rises, the flushing concentration needle of the concentration device absorbs the culture medium in the culture cup and washes the sample under high pressure for 1 minute, and the filter goes down The post-concentration device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com