Porous rapid combustion bio-combustible substance particle and preparation process thereof

A bio-combustion and fast-combustion technology, applied in the fuel, petroleum industry, solid fuel and other directions, can solve the problems of unfavorable transportation and storage, low combustion efficiency of biomass fuel, and difficulty in molding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

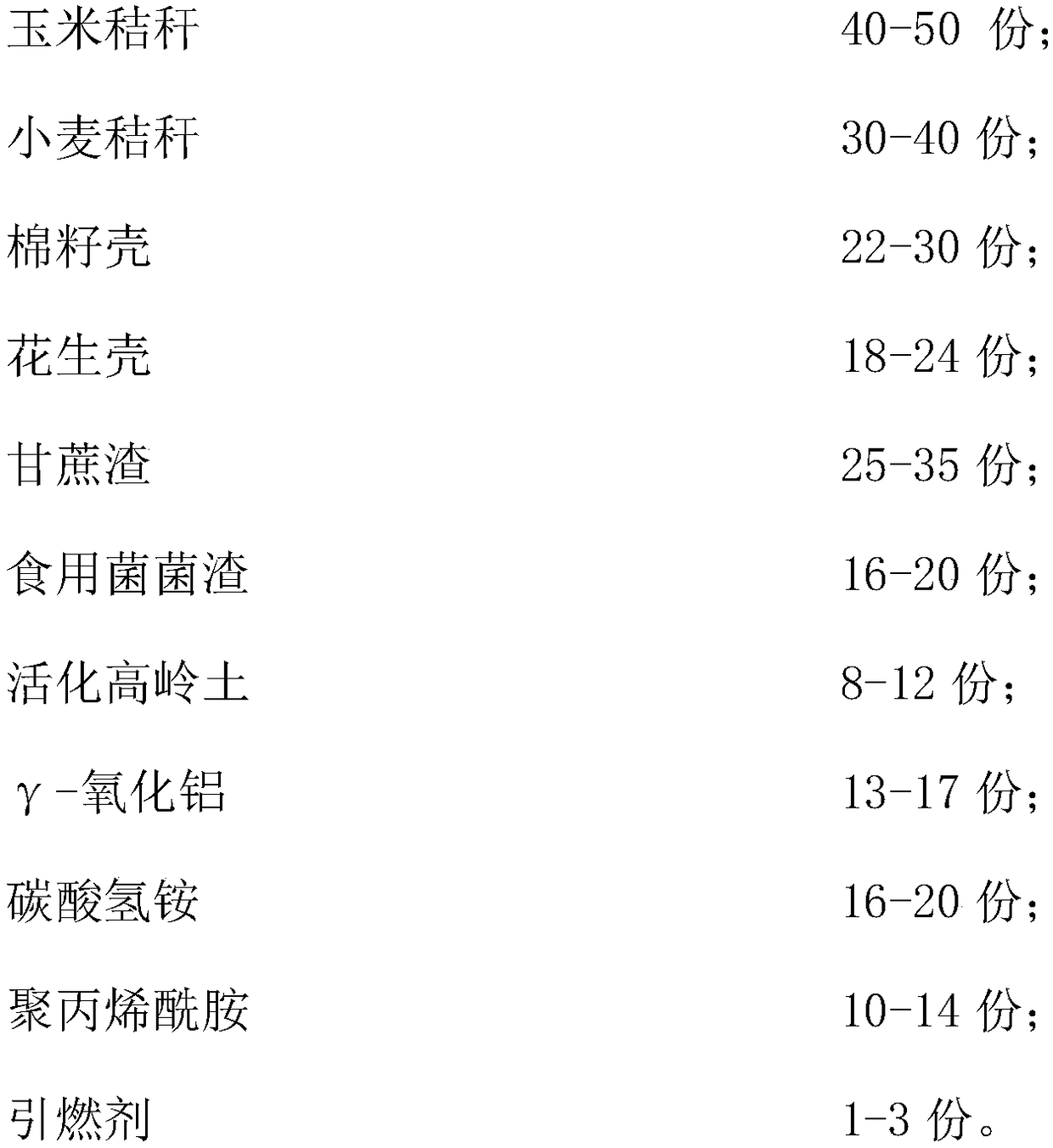

[0017] A porous and fast-burning bio-combustible particle, comprising the following raw materials in parts by weight:

[0018]

[0019] The preparation process of the above-mentioned porous and fast-burning bio-combustible particles comprises the following steps:

[0020] S1: Put kaolin in 0.2mol / L salicylic acid solution, soak for 3h, then add 0.1mol / LCa(OH) dropwise 2 solution, adjust the pH to 6.5, wash and dry, and calcinate at 500°C for 2 hours under the protection of nitrogen, and then sputter metal tin on the surface of kaolin with a deposition density of 0.4mg / cm 2 , get activated kaolin;

[0021] S2: Crush corn stalks, wheat stalks, cottonseed husks, peanut husks, bagasse, and edible fungus slag to 30 mesh, add ammonia water with a pH of 7.8 and soak for 1 hour, and then steam blast at 0.8 MPa and 130 °C for 6 times, 1.5min each time, after neutralization, washing and drying, the expanded biomass base material is obtained;

[0022] S3: Mix and expand biomass bas...

Embodiment 2

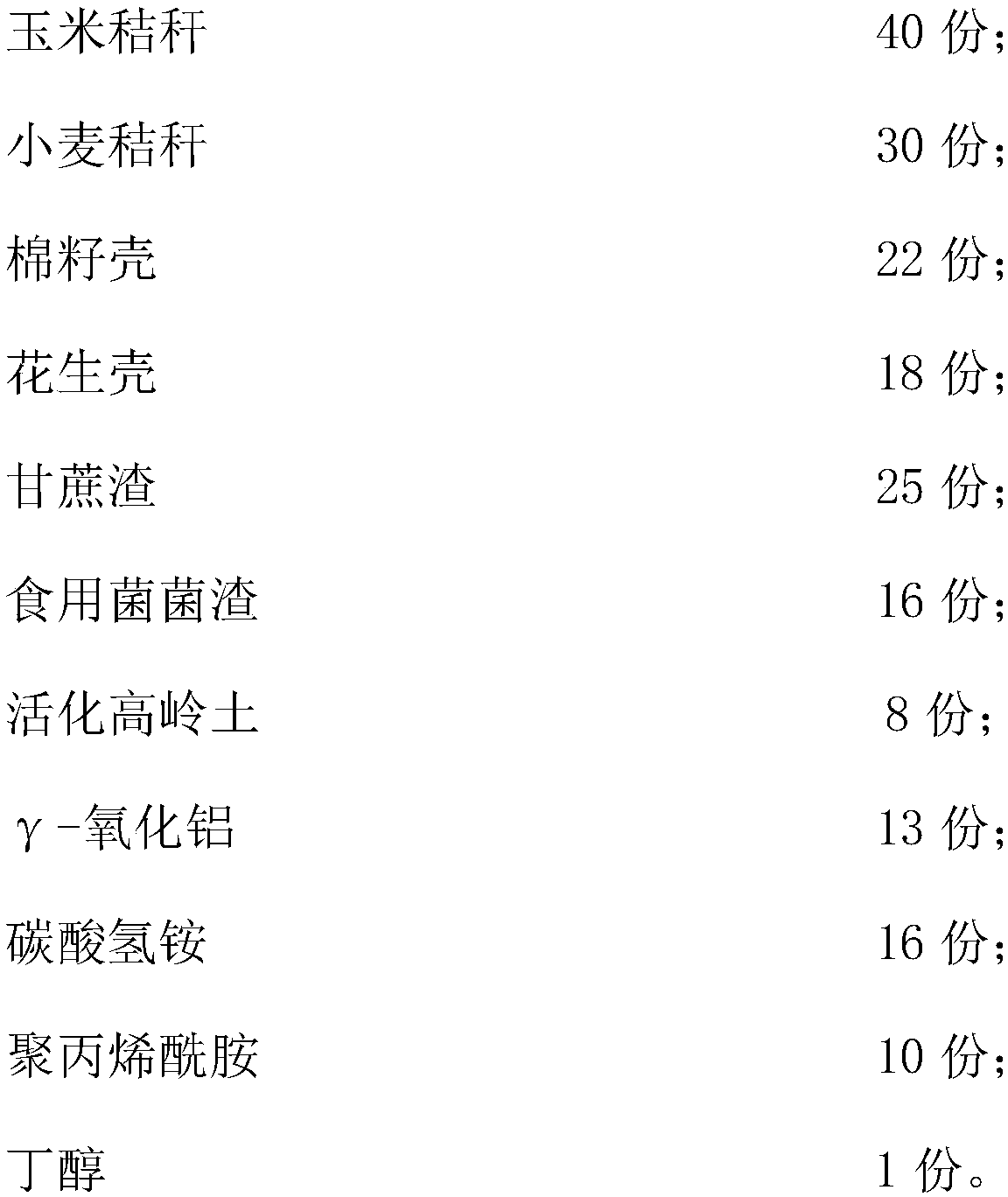

[0024] A porous and fast-burning bio-combustible particle, comprising the following raw materials in parts by weight:

[0025]

[0026] Preparation technology is with embodiment 1, difference is:

[0027] S1: The concentration of salicylic acid is 0.25mol / L, the pH is adjusted to 6.7, the calcination temperature is 600°C, and the deposition density is 0.7mg / cm 2 ;

[0028] S2: The crushing particle size is 35 mesh, the pH of ammonia water is 8.5, the steam explosion pressure and temperature are 1.4MPa and 140°C respectively, and the single explosion time is 1.7min;

Embodiment 3

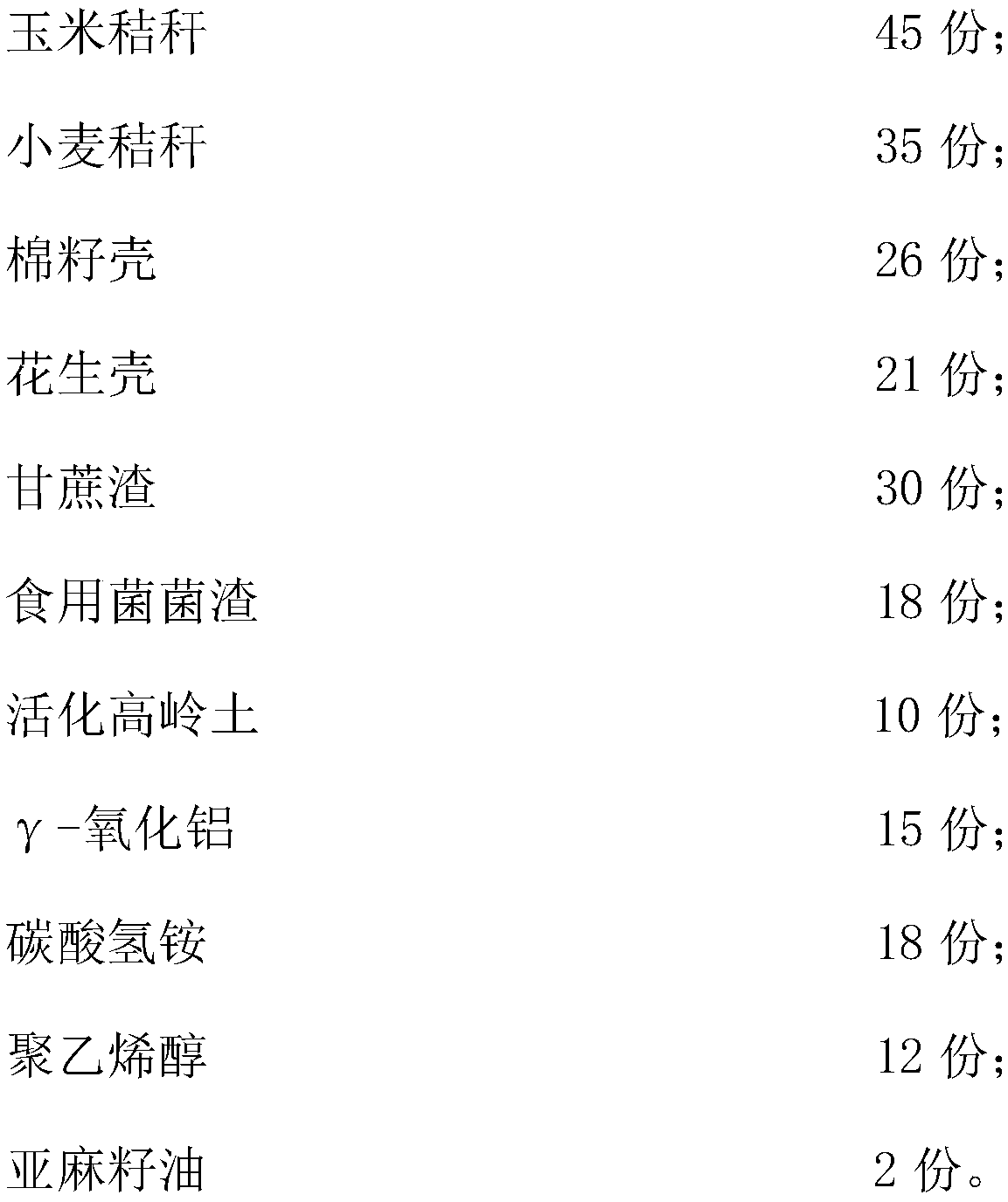

[0031] A porous and fast-burning bio-combustible particle, comprising the following raw materials in parts by weight:

[0032]

[0033] Preparation technology is with embodiment 1, difference is:

[0034] S1: The concentration of salicylic acid is 0.3mol / L, the pH is adjusted to 6.8, the calcination temperature is 700°C, and the deposition density is 1mg / cm 2 ;

[0035] S2: The crushing particle size is 40 mesh, the pH of ammonia water is 9.2, the steam explosion pressure and temperature are 2MPa and 150°C respectively, and the single explosion time is 2min;

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com