Fiber-reinforced nylon composite material and preparation method thereof

A nylon composite material and fiber-reinforced technology, which is applied in the field of fiber-reinforced nylon composite material and its preparation, can solve the problems of reducing the performance of polymer materials and low thermal conductivity, and achieve the improvement of thermal conductivity and mechanical properties, low thermal conductivity and waterproof. The effect of excellent impermeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

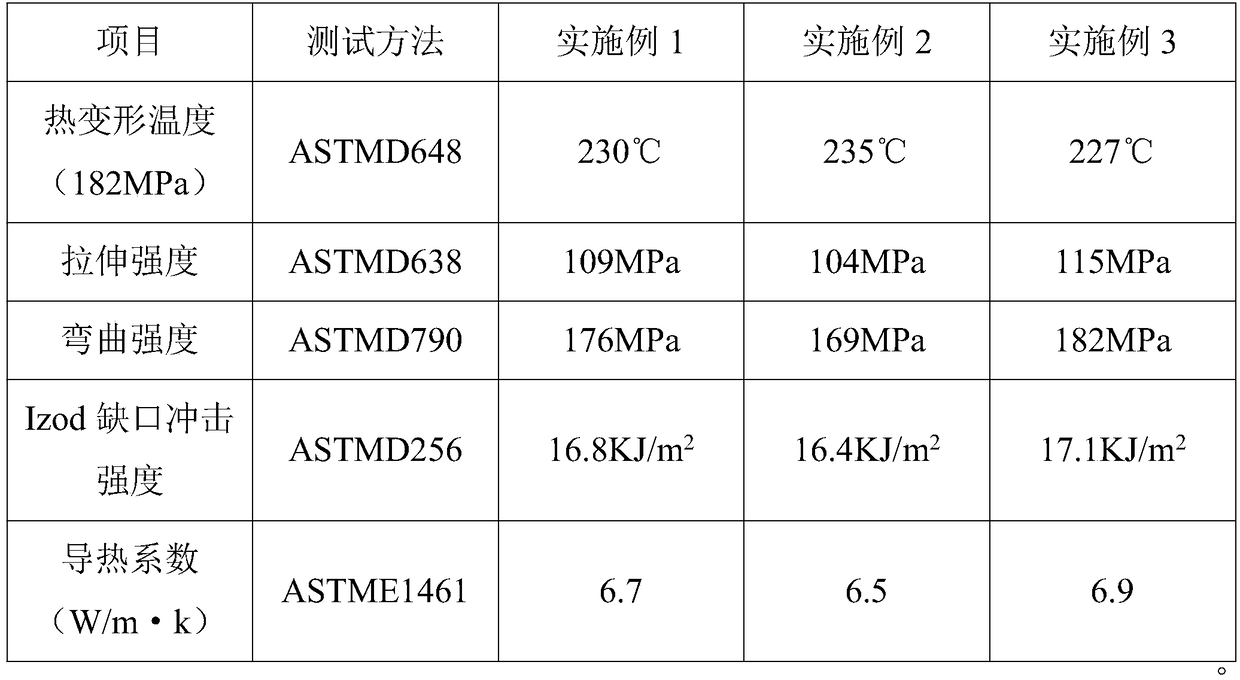

Examples

Embodiment 1

[0028] The preparation method of modified graphene comprises the following steps:

[0029] 1) graphene is added in the ethanol solution of oxalic acid and carries out ultrasonic dispersion, obtains the alcohol dispersion liquid of carboxylated graphene;

[0030] 2) Add sodium metaaluminate to the alcohol dispersion of carboxylated graphene, then carry out stirring reaction, centrifuge after the reaction finishes, obtain filtrate;

[0031] 3) Heat the filtrate to 400°C at a heating rate of 1°C / min under a nitrogen atmosphere, and keep it warm for 3 hours. The mass ratio of graphene to oxalic acid is 1:6, and the mass ratio of graphene to sodium metaaluminate is 1:3.

Embodiment 2

[0033] The preparation method of modified graphene comprises the following steps:

[0034] 1) graphene is added in the propanol solution of oxalic acid and carries out ultrasonic dispersion, obtains the alcohol dispersion liquid of carboxylated graphene;

[0035] 2) Add sodium metaaluminate to the alcohol dispersion of carboxylated graphene, then carry out stirring reaction, centrifuge after the reaction finishes, obtain filtrate;

[0036] 3) Heat the filtrate to 600°C at a heating rate of 5°C / min under nitrogen atmosphere, and keep it warm for 1h. The mass ratio of graphene to oxalic acid is 1:2, and the mass ratio of graphene to sodium metaaluminate is 1:7.

Embodiment 3

[0038] A fiber-reinforced nylon composite material, calculated in parts by weight, comprising the following raw materials:

[0039] 70 parts of nylon 66, 14 parts of silicone modified polyester acrylate, 7 parts of aramid fiber, 24 parts of modified graphene of embodiment 1, 6 parts of maleic anhydride grafted ethylene-octene copolymer, styrene- 1.2 parts of maleic anhydride copolymer, 0.4 parts of polyethylene wax and 0.4 parts of hindered phenolic antioxidant.

[0040] Preparation method of fiber reinforced nylon composite material:

[0041] 1) Nylon 66, maleic anhydride grafted ethylene-octene copolymer, aramid fiber and the modified graphene of Example 1 were mixed and stirred evenly, then added to a twin-screw extruder, and carried out at 260 ° C. Extrusion granulation to obtain thermal conductive nylon masterbatch;

[0042] 2) Dry the heat-conducting nylon masterbatch in step 1), and then mix and stir with silicone-modified polyester acrylate, styrene-maleic anhydride ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com