Composition for forming resist underlayer film with improved film density

A technology of resist lower layer and composition, which is applied in the direction of originals for photomechanical processing, photosensitive materials for photomechanical equipment, photoplate making process of patterned surface, etc., which can solve the problem of difficult to obtain resist pattern film thick and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

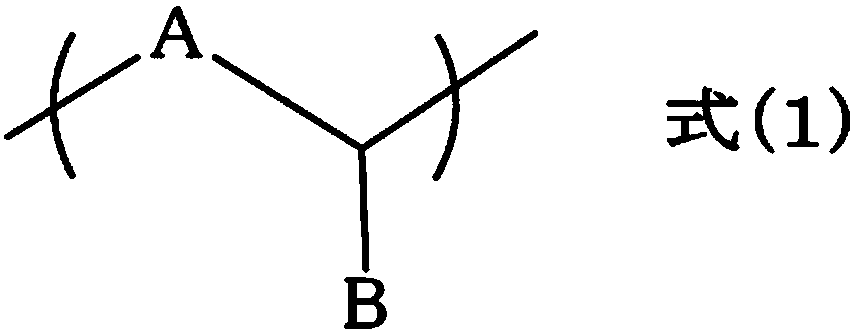

Method used

Image

Examples

Synthetic example 1

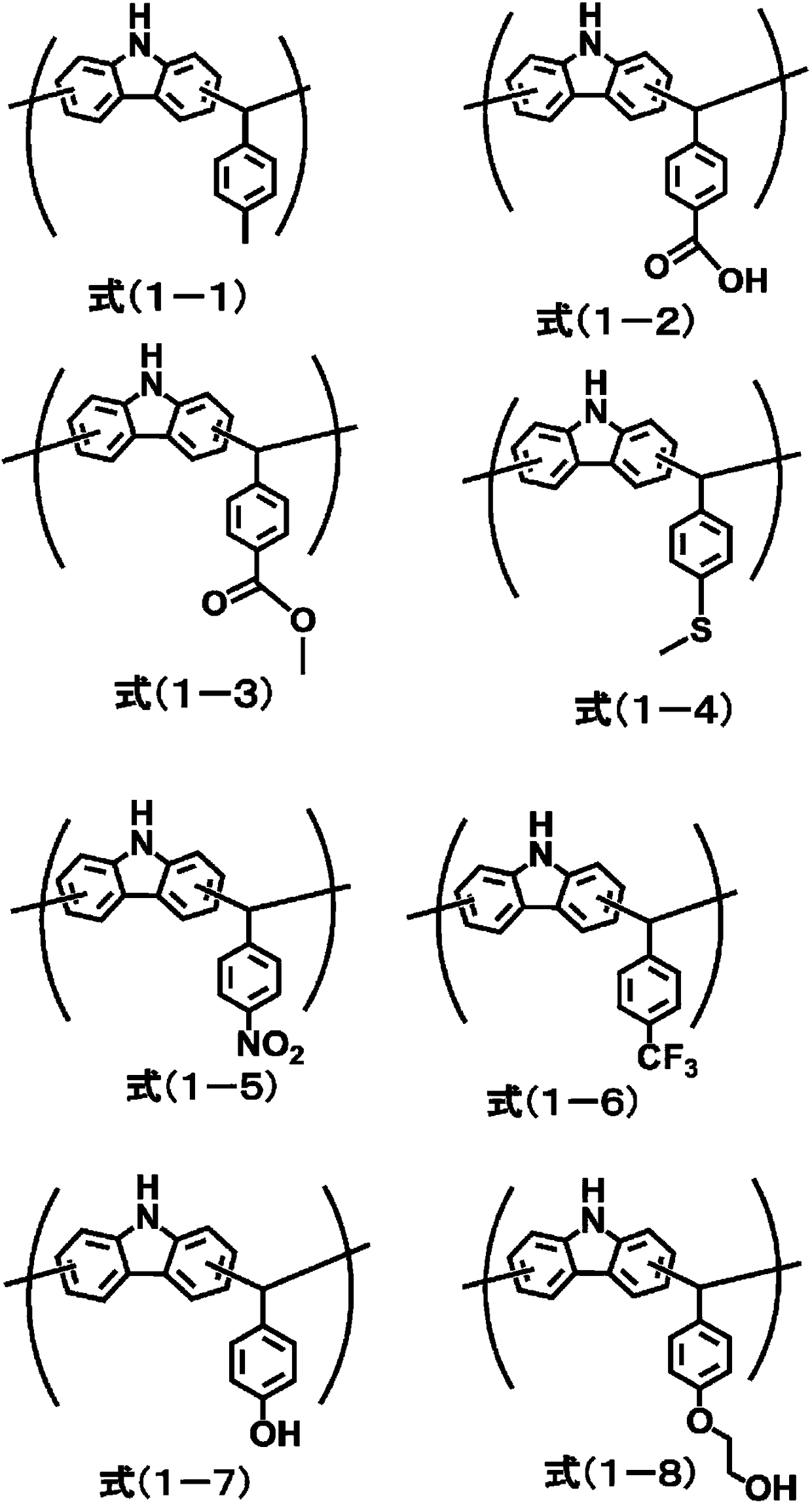

[0104] 9.00 g of carbazole (manufactured by Tokyo Chemical Industry Co., Ltd.), 6.47 g of p-tolualdehyde (manufactured by Tokyo Chemical Industry Co., Ltd.), 38.52 g of propylene glycol monomethyl ether acetate, and methanesulfonic acid were added to a 100 mL two-necked flask. (manufactured by Tokyo Chemical Industry Co., Ltd.) 1.04 g. It was then heated up to 150°C and stirred at reflux for about 1.5 hours. After completion of the reaction, it was diluted with 18.73 g of propylene glycol monomethyl ether acetate. This solution was added dropwise to a methanol solution for reprecipitation. The obtained precipitate was subjected to suction filtration, and the filtrate was dried under reduced pressure at 60° C. overnight. Thus, 12.2 g of powdery resin was obtained. The resulting polymer corresponds to formula (1-1). The weight average molecular weight Mw measured by GPC in terms of polystyrene was 82,700, and the polydispersity Mw / Mn was 13.5.

Synthetic example 2

[0106] Into a 100 mL two-necked flask, 8.00 g of carbazole (manufactured by Tokyo Chemical Industry Co., Ltd.), 7.19 g of p-formylbenzoic acid (manufactured by Tokyo Chemical Industry Co., Ltd.), 18.79 g of propylene glycol monomethyl ether acetate, propylene glycol monomethyl 18.79 g of base ether and 0.92 g of methanesulfonic acid (manufactured by Tokyo Chemical Industry Co., Ltd.). It was then heated up to 150°C and stirred at reflux for about 3.5 hours. After completion of the reaction, it was diluted with 22.25 g of propylene glycol monomethyl ether acetate. This solution was added dropwise to a methanol solution for reprecipitation. The obtained precipitate was subjected to suction filtration, and the filtrate was dried under reduced pressure at 60° C. overnight. Thus, 13.7 g of powdery resin was obtained. The resulting polymer corresponds to formula (1-2). The weight average molecular weight Mw measured by GPC in terms of polystyrene was 24,800, and the polydispersi...

Synthetic example 3

[0108]在100mL二口烧瓶中加入咔唑(东京化成工业株式会社制)8.00g、对甲酰基苯甲酸甲基酯(东京化成工业株式会社制)7.86g、丙二醇单甲基醚乙酸酯24.14g、甲磺酸(东京化成工业株式会社制)0.23g。然后加热直到150℃,回流搅拌约2小时。反应结束后,用丙二醇单甲基醚乙酸酯39.08g稀释。将该溶液滴加到甲醇溶液中,进行了再沉淀。将所得的沉淀物进行抽滤,将滤物在60℃减压干燥一晚。从而获得了粉末的树脂13.3g。所得的聚合物相当于式(1-3)。通过GPC以聚苯乙烯换算测定的重均分子量Mw为4,600,多分散度Mw / Mn为3.16。

PUM

| Property | Measurement | Unit |

|---|---|---|

| polydispersity index | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com