A wetting method for high-capacity high-pressure negative electrode lithium ion battery

A lithium-ion battery, high-pressure compaction technology, applied in the direction of secondary batteries, battery pack components, non-aqueous electrolyte storage batteries, etc., can solve the problems of high fluid loss of batteries, difficult infiltration at room temperature, and unsatisfactory cycle life. Achieve the effects of enhanced cycle life, improved ability to adsorb electrolyte, and reduced soaking time and waiting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

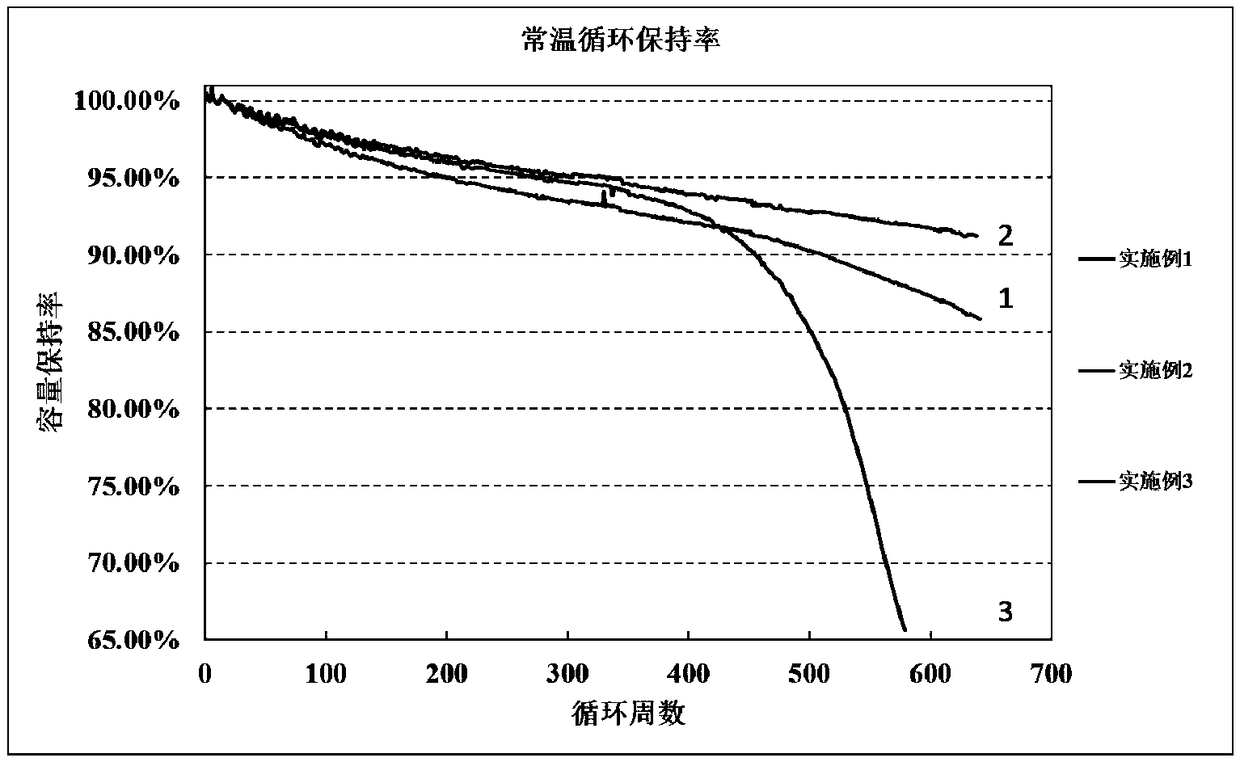

Embodiment 1

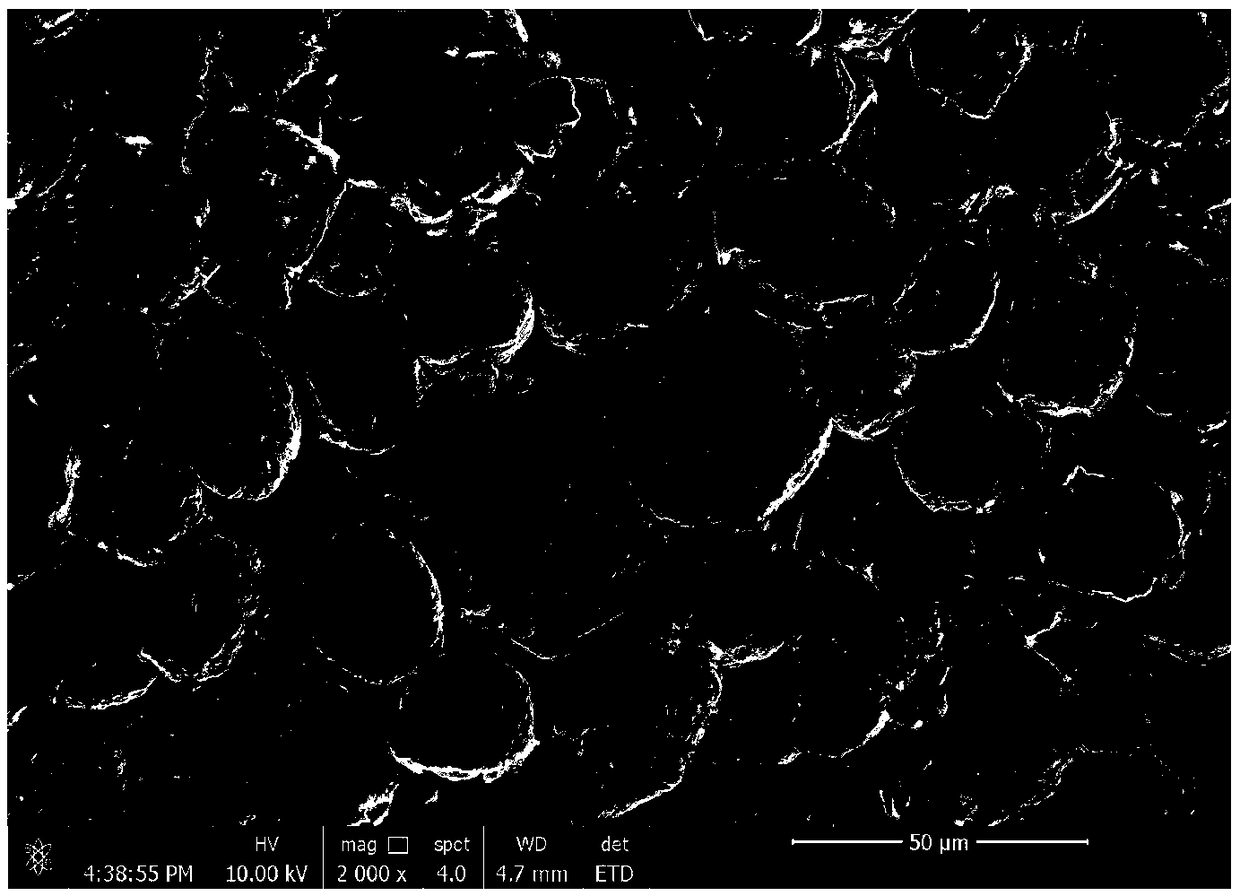

[0028] The low porosity and high compaction negative electrode material that the infiltration method of the present invention obtains sees figure 1 , a method for impregnating a high-capacity and high-pressure negative electrode lithium-ion battery, the specific steps are as follows:

[0029] 1) Liquid injection by vacuuming: place the prepared cylindrical battery on a liquid injection stand with graduated metering, and put in 105% of the required amount of electrolyte. Put the liquid injection rack in the vacuum box for vacuuming. The vacuum degree of the vacuum box is controlled at -0.09MPa. The vacuum holding time is 2 minutes, and then the pressure is released. The end of the pressure relief pipe is connected to an exhaust gas treatment device. Let the electrolyte slowly permeate inside the cell, and then cycle three times;

[0030] 2) Shelving at high temperature: Shelve the unsealed battery cell after vacuuming and injecting liquid at a temperature of 35°C, with the liq...

Embodiment 2

[0037] A kind of soaking method of high-capacity and high-pressure negative electrode lithium-ion battery, concrete steps are as follows:

[0038] 1) Liquid injection by vacuuming: place the prepared cylindrical battery on a liquid injection stand with graduated metering, and put in 105% of the required amount of electrolyte. Put the liquid injection rack in the vacuum box for vacuuming. The vacuum degree of the vacuum box is controlled at -0.09MPa. The vacuum holding time is 2 minutes, and then the pressure is released. The end of the pressure relief pipe is connected to an exhaust gas treatment device. Let the electrolyte slowly permeate inside the cell, and then cycle three times;

[0039] 2) Shelving at high temperature: Shelve the unsealed battery cell after vacuuming and injecting liquid at a temperature of 40°C, with the liquid injection port facing up, for 10 hours, and at the same time, fill the oven with nitrogen for protection;

[0040] 3) Pre-formation: On the cha...

Embodiment 3

[0046] The low-porosity high-compact negative electrode material used in the infiltration method of the present invention is shown in figure 1 ,Specific steps are as follows:

[0047] 1) Liquid injection by vacuuming: place the prepared cylindrical battery on a liquid injection stand with graduated metering, and put in 105% of the required amount of electrolyte. Put the liquid injection stand in the vacuum box for vacuuming, the vacuum degree of the vacuum box is controlled at -0.095MPa, the vacuum holding time is 2 minutes, and then the pressure is released. The end of the pressure relief pipe is connected to an exhaust gas treatment device. After the pressure relief, the shelf time is 10 minutes. Let the electrolyte slowly permeate inside the cell, and then cycle three times;

[0048] 2) Shelving at high temperature: Shelve the unsealed battery cells after vacuuming and injecting liquid at a temperature of 35°C, with the liquid injection port upward, for 8 hours, and at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com