High-voltage lithium ion battery, battery pole piece and infiltration method thereof

A lithium-ion battery, high-voltage technology, which is applied in non-aqueous electrolyte battery electrodes, non-aqueous electrolyte batteries, and electrolyte battery manufacturing, etc. Longer and other problems, to solve the general infiltration difficulties, improve high internal resistance and short life, increase the effect of vibration shelving operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

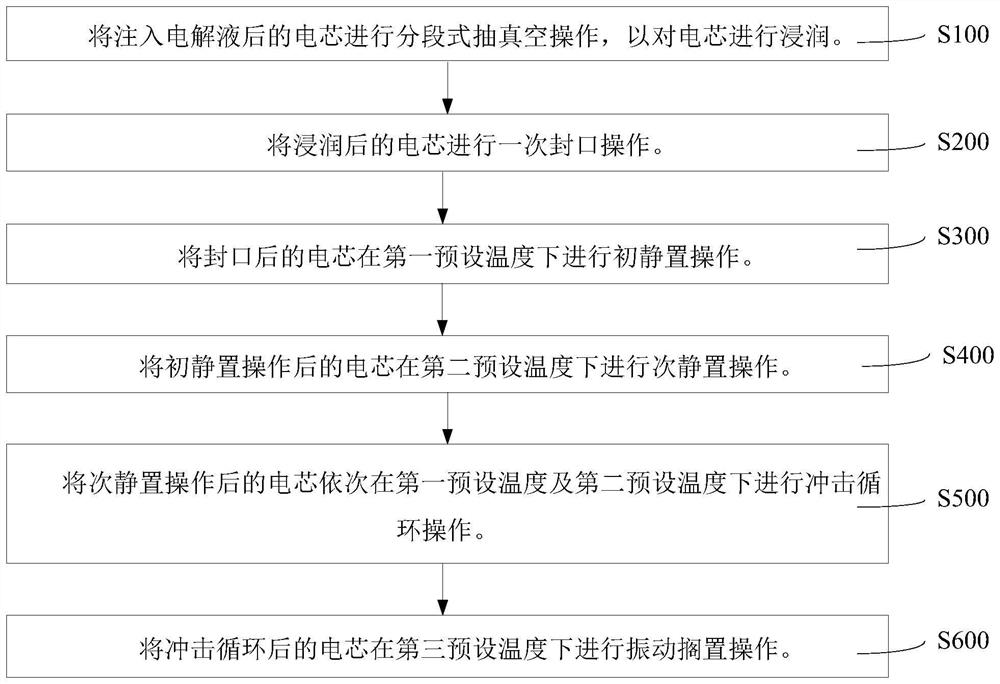

[0060] Place the battery cell that has just been injected with electrolyte but has not been sealed once in the vacuum box. The vacuum box is divided into three stages of vacuuming process. After the vacuuming is completed, the vacuum is left for 5 minutes. Put the battery cells that have been left in vacuum and sealed for a time in a tunnel oven at 25°C for 8 hours at room temperature; transfer the cells that have been left for the first time to a high-temperature tunnel oven at 60°C Perform high-temperature standing, and set the standing time to 5 hours; perform normal-high temperature shock cycle operation according to the method of normal temperature standing to high temperature standing, cycle the above normal temperature standing and high temperature standing steps, and set the number of cycles to 2 times; After completing the above-mentioned impact cycle operation steps, the cells were transferred to a high-temperature static room at 40°C, and vibrated on a low-frequency ...

Embodiment 2

[0062] Place the battery cell that has just been injected with electrolyte but has not been sealed once in the vacuum box. The vacuum box is divided into three stages of vacuuming process. After the vacuuming is completed, the vacuum is left for 10 minutes. Put the battery cells that have been placed in vacuum and sealed once in a tunnel oven at 30°C at room temperature for 10 hours; transfer the cells that have been left to stand for the first time to a high-temperature tunnel oven at 80°C Perform high-temperature standing, and set the standing time to 8 hours; perform normal-high temperature shock cycle operation according to the method of normal-temperature standing to high-temperature standing, and cycle the above-mentioned normal-temperature standing and high-temperature standing steps, and the number of cycles is set to 5 times; After completing the above-mentioned impact cycle operation steps, transfer the cell to a high-temperature static room at 50°C, and vibrate on a ...

Embodiment 3

[0064] Place the battery cell that has just been injected with electrolyte but has not been sealed once in the vacuum box. The vacuum box is divided into three stages of vacuuming process. After the vacuuming is completed, the vacuum is left for 8 minutes. Put the battery cells that have been placed in vacuum and sealed once in a tunnel oven at 27°C at room temperature for 9 hours; transfer the cells that have been left to stand for the first time to a high-temperature tunnel oven at 70°C Perform high-temperature standing, and set the standing time to 6 hours; perform normal-high temperature shock cycle operation according to the method of normal-temperature standing to high-temperature standing, and cycle the above-mentioned normal-temperature standing and high-temperature standing steps, and the number of cycles is set to 3 times; After completing the above-mentioned impact cycle operation steps, the cells were transferred to a high-temperature static room at 45°C, and vibrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com