A kind of manufacturing method of positive electrode of lithium-sulfur battery

A production method and lithium-sulfur battery technology, applied in electrode manufacturing, battery electrodes, circuits, etc., can solve the problems of high volatility environment, harmfulness to operators, cumbersome production process, etc., achieve large reaction active surface, reduce impedance and extremely degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] The carbon material used as the matrix is mesoporous carbon prepared by SBA15 template method and KB600 carbon powder in a mass ratio of 2:1 to 1:2, and the binder is polyvinylidene fluoride with a molecular weight of 900,000 to 1 million. between.

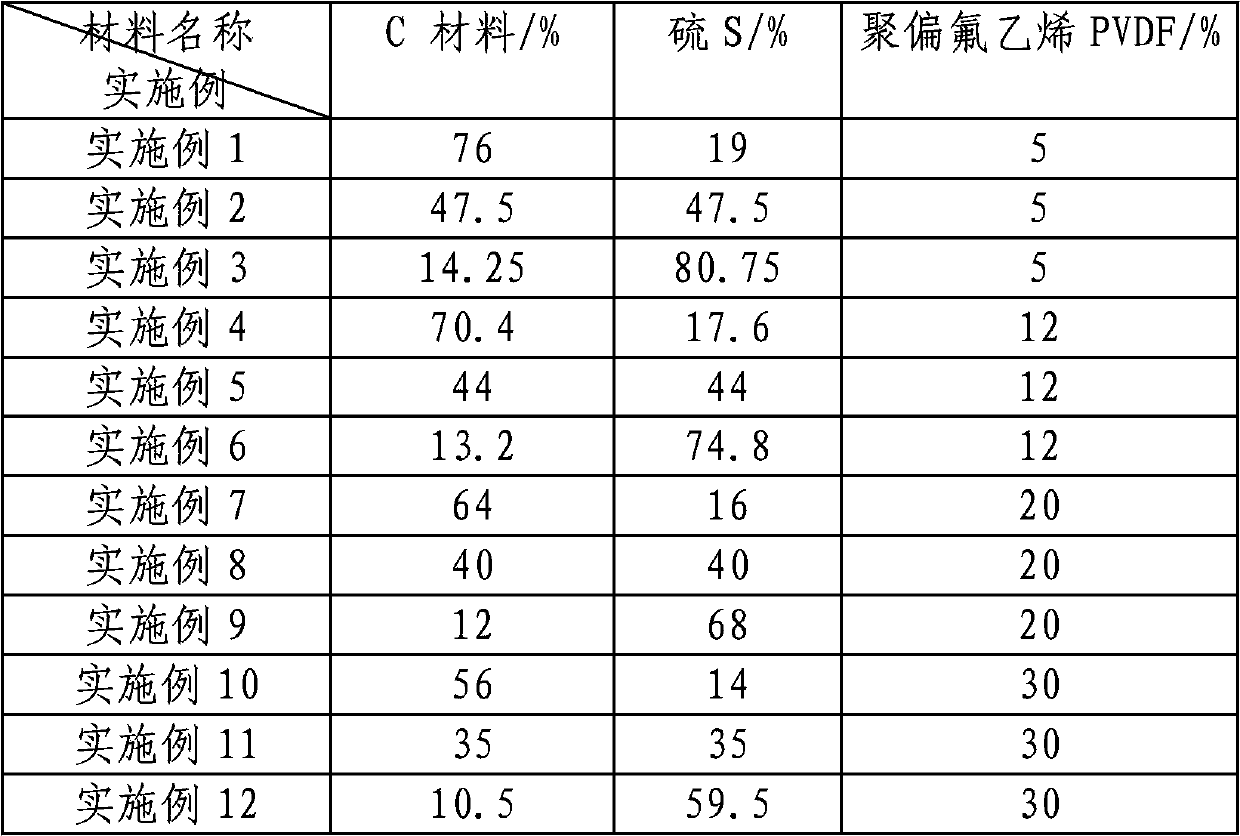

[0039] Example scheme

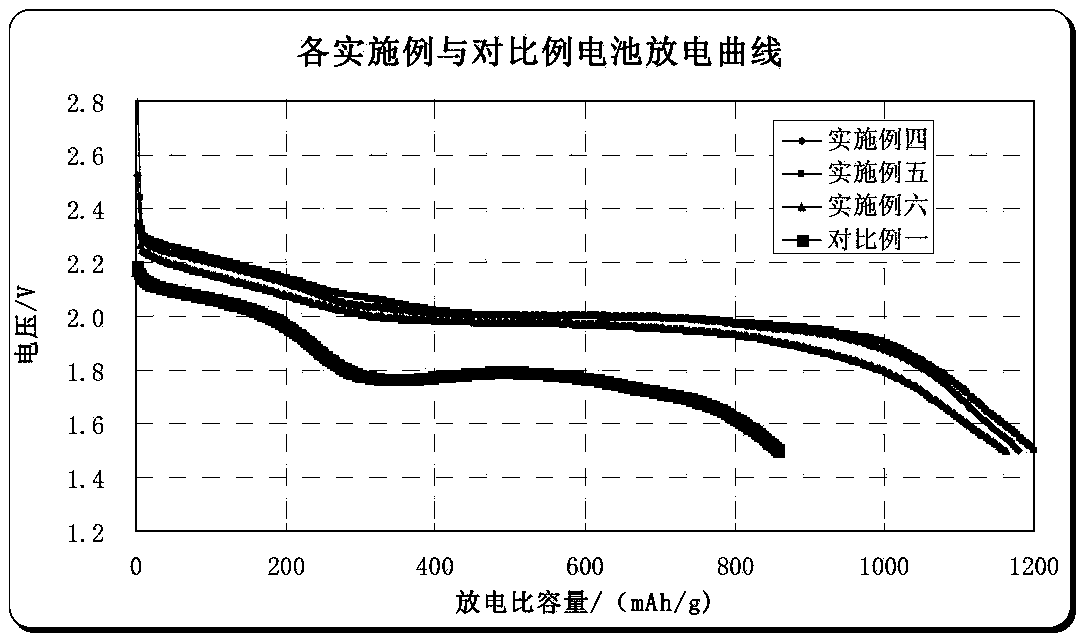

[0040] The mass ratio percentage of each material ratio of the positive electrode of the embodiment of table 1

[0041]

[0042] The above table is the mass proportion of various substances in the specific examples.

[0043] Specific method: (1) Weigh the matrix carbon material and sulfur powder according to the specific gravity in the table, ball mill for more than 4 hours, weigh PVDF powder according to the specific gravity and add it to the carbon-sulfur mixture, ball mill again for more than 2 hours, and add the dispersant N-methyl Pyrrolidone NMP, so that the solid content in the slurry is 30%, and after mixing evenly, ball milling for more than 4 hours to obtain the slurry; (2) The slurr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com