Negative plate, lithium ion battery and preparation method thereof

A lithium-ion battery and negative electrode technology, which is applied in the manufacture of electrolyte batteries, secondary batteries, battery electrodes, etc., can solve problems such as poor cycle performance, large volume change, and battery capacity drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

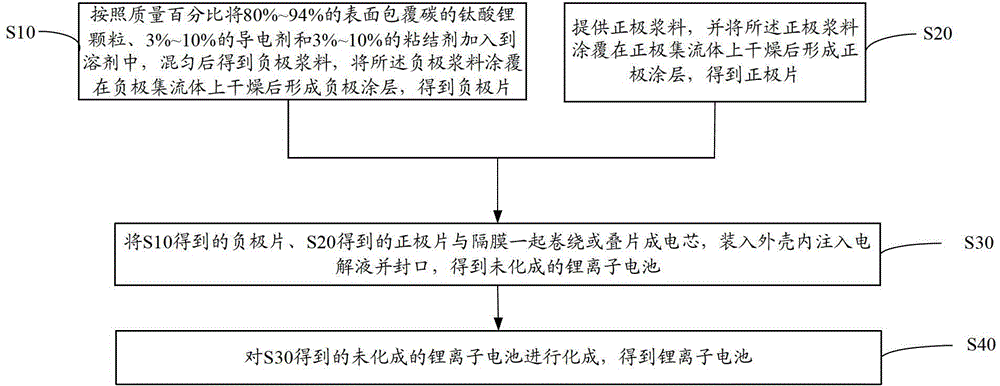

[0063] Such as figure 1 The preparation method of above-mentioned lithium ion battery shown, comprises the steps:

[0064] S10. According to the mass percentage, add 80%~94% of lithium titanate particles coated with carbon on the surface, 3%~10% of conductive agent and 3%~10% of binder into the solvent, and mix well to obtain the negative electrode Slurry, the negative electrode slurry is coated on the negative electrode current collector and dried to form a negative electrode coating to obtain a negative electrode sheet.

[0065] In the negative electrode slurry, the solute solid content is 30%~70%.

[0066] The negative electrode slurry is coated on both sides of the negative electrode current collector, and the negative electrode sheet is prepared by baking, rolling and slicing.

[0067] The solvent can be N-methylpyrrolidone (NMP), dimethylamide or dimethylacetamide.

[0068] The conductive agent is at least one of super conductive carbon black, conductive graphite and ...

Embodiment 1

[0096] Add 90% of lithium titanate coated with carbon on the surface, 3% of SP, 2% of KS-6 and 5% of PVDF into the stirring tank according to the mass percentage, vacuumize and stir, add an appropriate amount of NMP and continue stirring to obtain the negative electrode Slurry, the negative electrode slurry is coated on both sides of the 20μm thick porous corroded aluminum foil after corrosion treatment, and the surface density of the pole piece coating is 250g / m 2 , through baking, rolling and slicing to prepare the negative electrode sheet.

[0097] 94% LiMn by mass ratio 2 o 4 , 1.5% SP, 1.5% KS-6 and 3% PVDF were dissolved in NMP and stirred to make positive electrode slurry, and the positive electrode slurry was coated on both sides of the light aluminum foil with a surface density of 400g / m 2 , through baking, rolling and slicing to prepare the positive electrode sheet.

[0098] By controlling the surface density of the coating, the ratio of the capacity per unit area...

Embodiment 2

[0103] Different from Example 1, the positive electrode active material is LiMn 2 o 4 with LiCoO 2 Mixture (weight ratio: 8:2), the positive electrode coating is coated on both sides of the light aluminum foil, the surface density is 370g / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com