Adhesive rubber water stop without isolation film, and preparation method thereof

A technology of rubber waterstop and self-adhesive rubber, applied in adhesives, water conservancy projects, adhesive types, etc., can solve the problems of waterstop loss of waterproof effect, loss of adhesion, and unstable bonding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

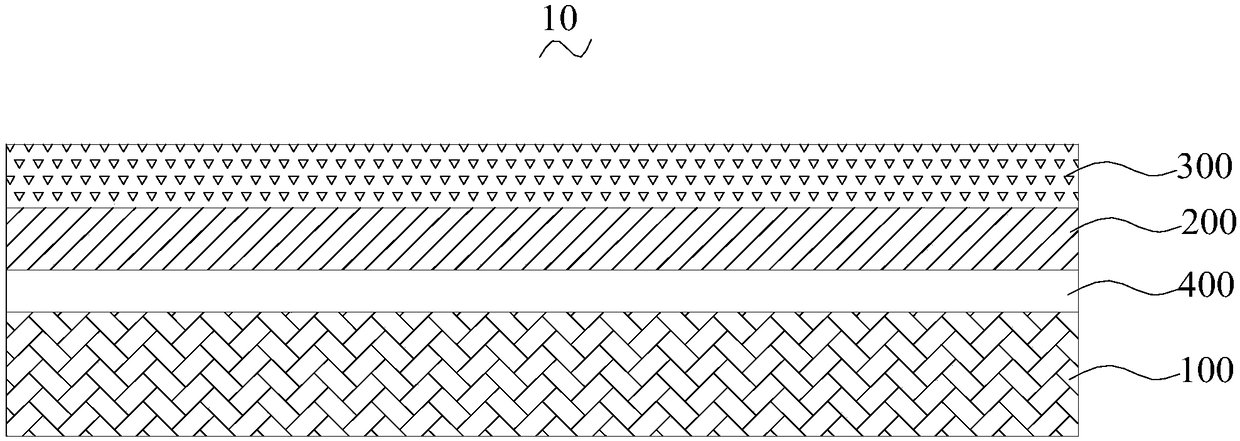

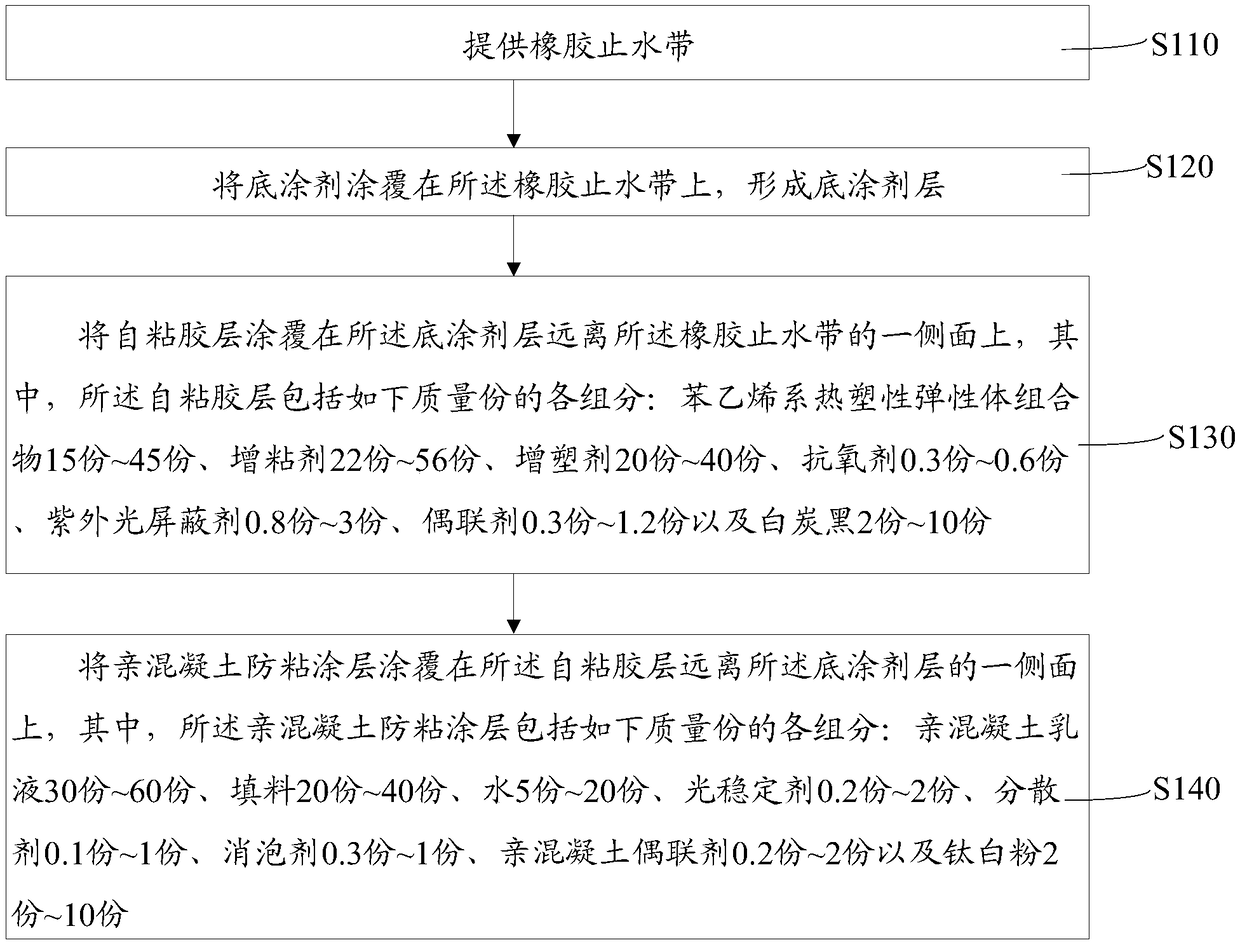

[0053] see figure 2 , a method for preparing a peel-free self-adhesive rubber waterstop, comprising the steps of:

[0054] S110. Provide a rubber waterstop.

[0055] It can be understood that the rubber waterstop 100 has high elasticity and can be in close contact with concrete to seal the gaps formed during concrete pouring and play a good role in preventing water leakage or seepage of the building structure. In one of the embodiments, the material of the rubber waterstop 100 is natural rubber, EPDM or neoprene. It can be understood that natural rubber, EPDM and neoprene all have good physical properties. The mechanical properties can meet the high requirements of construction engineering on the puncture resistance of the waterstop. The thickness of the rubber waterstop is 6mm to 10mm. Of course, in other embodiments, the thickness of the rubber waterstop can also be other value, the thickness of the rubber waterstop 100 can be adjusted according to actual needs.

[0056]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com