Method for extracting cannabidiol

A technology of cannabidiol and hemp, which is applied in the field of industrial extraction, can solve the problems of difficult to realize industrial scale-up production, low solubility of cannabidiol, product safety impact, etc., achieve good promotion and use value, shorten extraction time, and save solvent consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] 1) Pretreatment: After screening 10Kg of the flower leaves of the cannabis plant in the flowering stage, spread them flat in an oven for drying treatment at a temperature of 100-130°C for 2-3 hours until the content of the cannabis flower leaves The amount of water is less than 6%, and then it is added into a pulverizer to grind and pulverize until the particle size is 10-20 mesh;

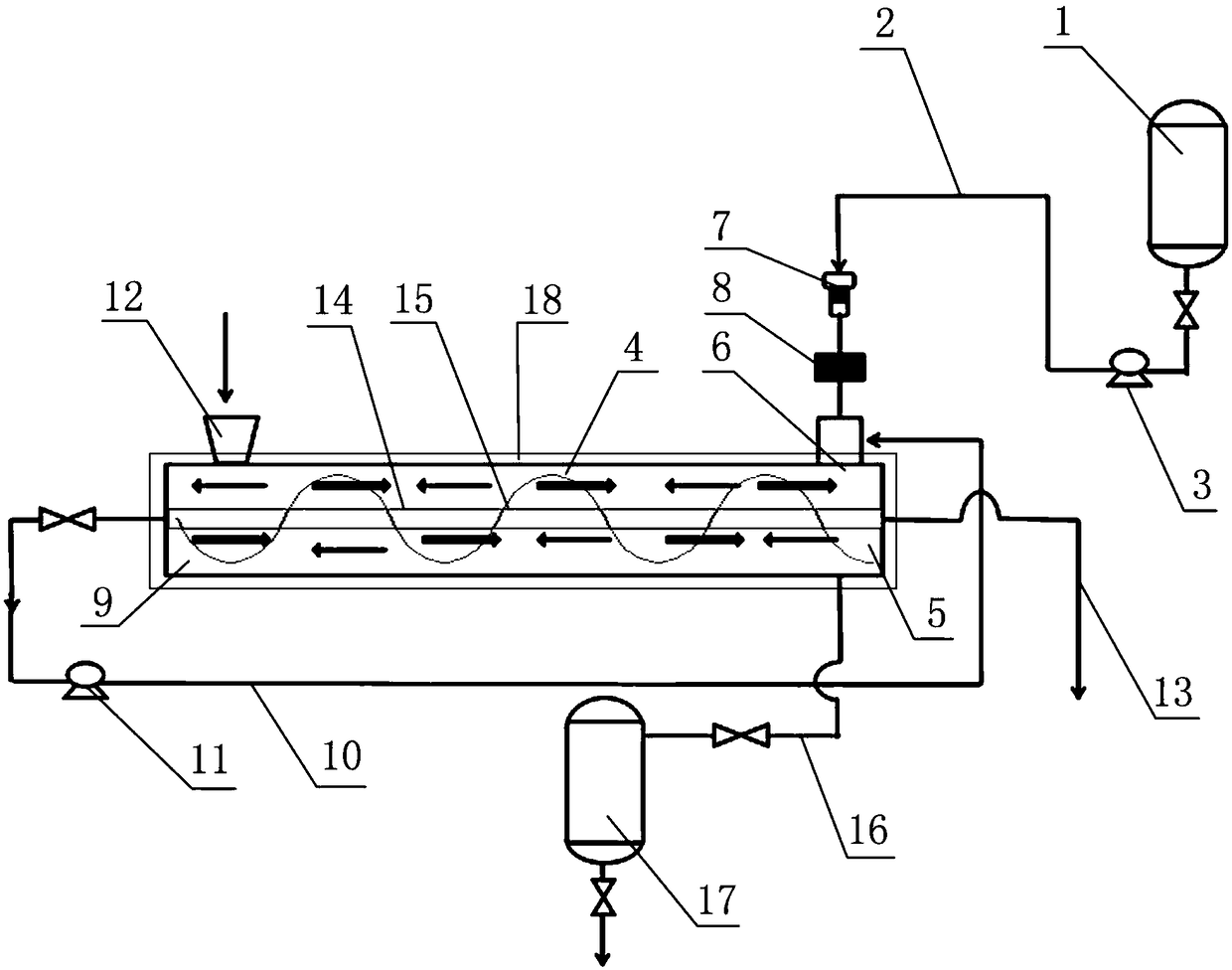

[0077] 2) Continuous extraction: the dried and pulverized hemp mosaic powder is evenly fed into the feeding port through the quantitative feeding device, and then the hemp mosaic powder is pushed from one end to the other under the action of the screw propeller inside the device The discharge device is automatically discharged according to the certain time required by the process; while the solvent is quantitatively added by the flow meter at the other end according to the required solid-liquid ratio according to the process requirements, so that the trend of the cannabis flower leaf coarse p...

Embodiment 2

[0083] 1) Pretreatment: After screening 100Kg of the flower leaves of the cannabis plant in the flowering stage, spread them flat in an oven for drying treatment at a temperature of 100-130°C for 2-2.5 hours until the content of the cannabis leaves The amount of water is less than 6%, and then it is added into a pulverizer to grind and pulverize until the particle size is 10-20 mesh;

[0084] 2) Continuous extraction: the dried and pulverized hemp mosaic powder is evenly fed into the feeding port through the quantitative feeding device, and then the hemp mosaic powder is pushed from one end to the other under the action of the screw propeller inside the device The discharge device is automatically discharged according to the certain time required by the process; while the solvent is quantitatively added by the flow meter at the other end according to the required solid-liquid ratio according to the process requirements, so that the trend of the cannabis flower leaf coarse powde...

Embodiment 3

[0090] 1) Pretreatment: After screening 10Kg of the flower leaves of cannabis plants in the flowering stage, spread them flat in an oven for drying treatment at a temperature of 100-130°C for 2-2.5 hours until the content of cannabis leaves The amount of water is less than 6%, and then it is added into a pulverizer to grind and pulverize until the particle size is 10-20 mesh;

[0091] 2) Soaking and extracting: put the dried and crushed marijuana flowers and leaves in an airtight container, add 95% ethanol according to the ratio of material to liquid 1:10 (W / V), soak and extract 3 times, each time for 2-3 hours, and filter Separating the waste residue from the aqueous solution and combining the extracts;

[0092] 3) Concentration: heating the extract obtained above under reduced pressure (65-75° C.) and evaporating excess ethanol to dryness;

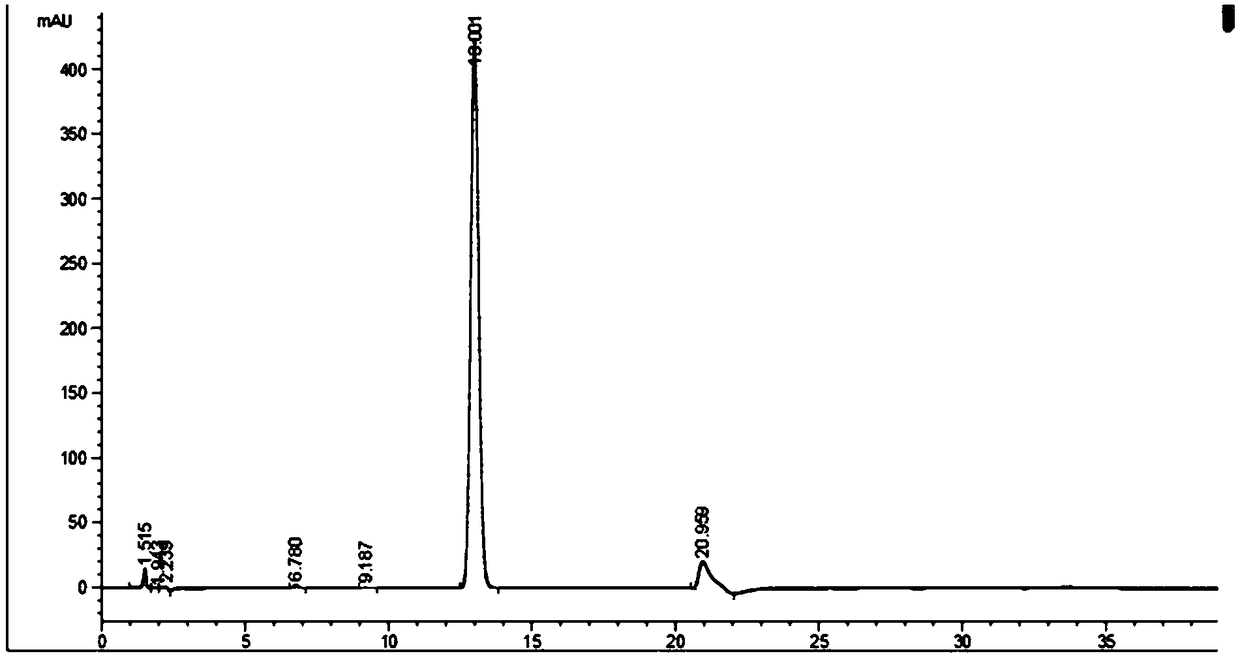

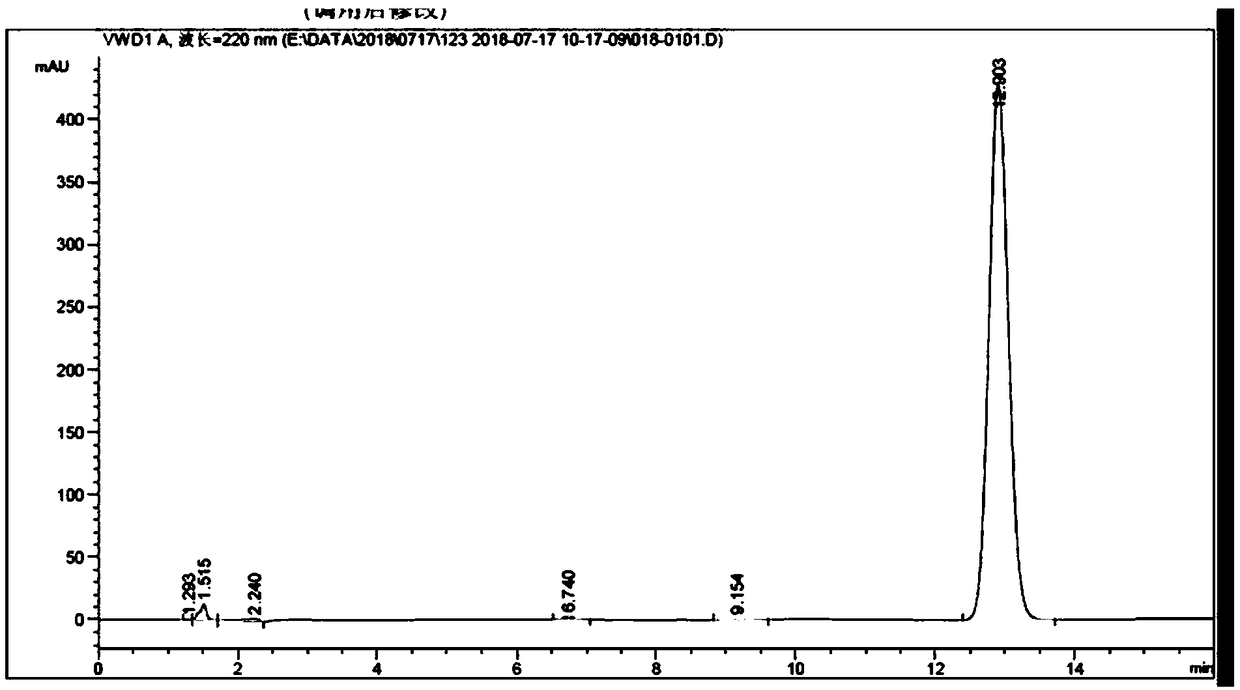

[0093] 4) Column chromatography: add the concentrated solution of cannabidiol to dilute with pure water, so that the solid content of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com