Fe-Cr-Ni-Ti micropowder coated honeycomb ZTA ceramic preform as well as preparation and application thereof

A fe-cr-ni-ti, honeycomb technology, used in ceramic products, applications, other household appliances, etc., can solve the problems of ceramic preform size limit, composite interface tearing, non-wetting, etc., to improve Interfacial bonding properties, improving metallurgical bonding strength, and improving wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] 1) Take Fe, Cr, Ni, Ti powder with a purity of about 99.99%, particle size less than 200 mesh, Fe: 75%, Cr: 10.8%, Ni: 13.3%, Ti: 0.90% by weight, and alloy Chemical treatment, main mechanical alloying parameters: ball diameter: 5mm, ball to material ratio 10:1, speed 400r / min, ball milling time 48h. Usually the whole process of ball milling and powder filling is carried out under the environment of inert gas;

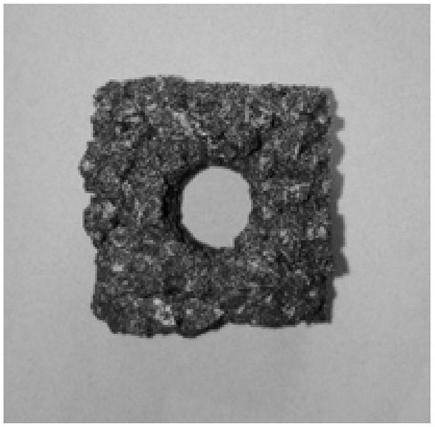

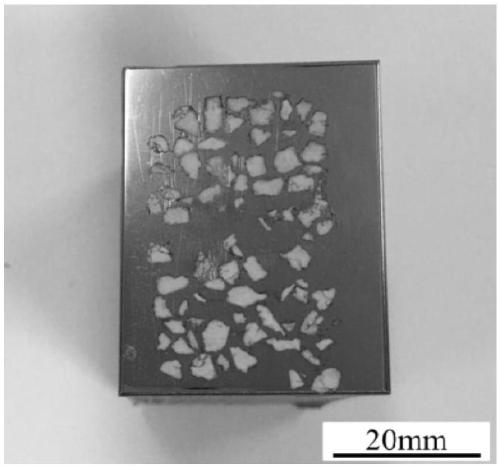

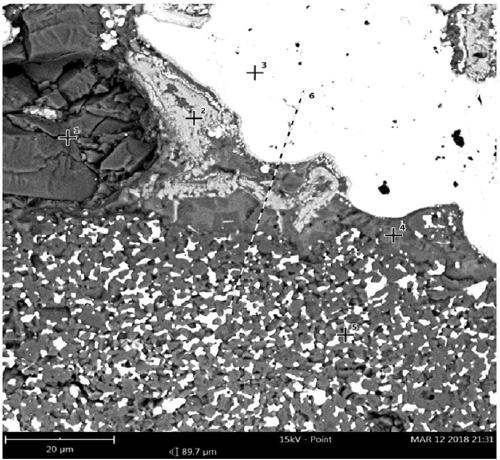

[0050] 2) In a 30mm×20mm×10mm cavity and a through Φ10mm cylindrical mold, add the Fe, Cr, Ni, Ti micropowder and ZTA ceramic particles obtained in step (1), then add water glass, and then add 10~ 12 purpose paraffin, wherein choose Fe, Cr, Ni, Ti mixed micropowder 2.4g, ZTA ceramic particles (ZrO 2 20wt.%, Al 2 o 3 Accounting for 80wt.%) 30g, the amount of water glass is 0.12g, 10-12 mesh paraffin wax particles are added as 0.65g as a pore-forming agent, the four are evenly mixed and processed, and the whole process is carried out in a protective atmosphere....

Embodiment 2

[0056] 1) Take Fe, Cr, Ni, Ti powder with a purity of about 99.99%, particle size less than 200 mesh, Fe: 78%, Cr: 10.0%, Ni: 11.0%, Ti: 1.0% by weight, and alloy Chemical treatment, main mechanical alloying parameters: ball diameter: 5mm, ball to material ratio 10:1, speed 400r / min, ball milling time 48h. Usually the whole process of ball milling and powder filling is carried out under the environment of inert gas;

[0057] 2) In a 30mm×20mm×10mm cavity and a through Φ10mm cylindrical mold, first add the Fe, Cr, Ni, Ti micropowder and ZTA ceramic particles obtained in step (1), then add water glass, and then add 10 ~12 purpose paraffin wax, wherein choose Fe, Cr, Ni, Ti mixed micropowder 2.4g, ZTA ceramic particles (ZrO 2 20wt.%, Al 2 o 3 Accounting for 80wt.%) 30g, the amount of water glass is 0.12g, 0.65g of 10-12 mesh paraffin particles are added as a pore-forming agent, and the four are uniformly mixed and processed, and the whole process is carried out in a protective...

Embodiment 3

[0062] 1) Take Fe, Cr, Ni, Ti powder with a purity of about 99.99%, particle size less than 200 mesh, Fe: 78.3%, Cr: 10%, Ni: 10.5%, Ti: 1.2% by weight, and mix the powder for alloying Chemical treatment, main mechanical alloying parameters: ball diameter: 5mm, ball to material ratio 10:1, speed 400r / min, ball milling time 48h. Usually the whole process of ball milling and powder filling is carried out under the environment of inert gas;

[0063] 2) In a 30mm×20mm×10mm cavity and a through Φ10mm cylindrical mold, add the Fe, Cr, Ni, Ti micropowder and ZTA ceramic particles obtained in step (1), then add water glass, and then add 10~ 12 purpose paraffin, wherein choose Fe, Cr, Ni, Ti mixed micropowder 2.4g, ZTA ceramic particles (ZrO 2 20wt.%, Al 2 o 3 Accounting for 80wt.%) 30g, the amount of water glass is 0.12g, 0.65g of 10-12 mesh paraffin particles are added as a pore-forming agent, the four are uniformly mixed, and the whole process is carried out in a protective atmos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Crush strength | aaaaa | aaaaa |

| Crush strength | aaaaa | aaaaa |

| Crush strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com