Basalt fiber preparation method, mineral mixture and production technology

A technology of basalt fiber and mixture, which is applied in the field of materials, can solve the problems of narrow source of raw materials, fluctuations in composition, costing a lot of manpower and financial resources, etc., and achieve the effects of short mixing time, sufficient mixing reaction, and improved drawing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5、 comparative example 1~2

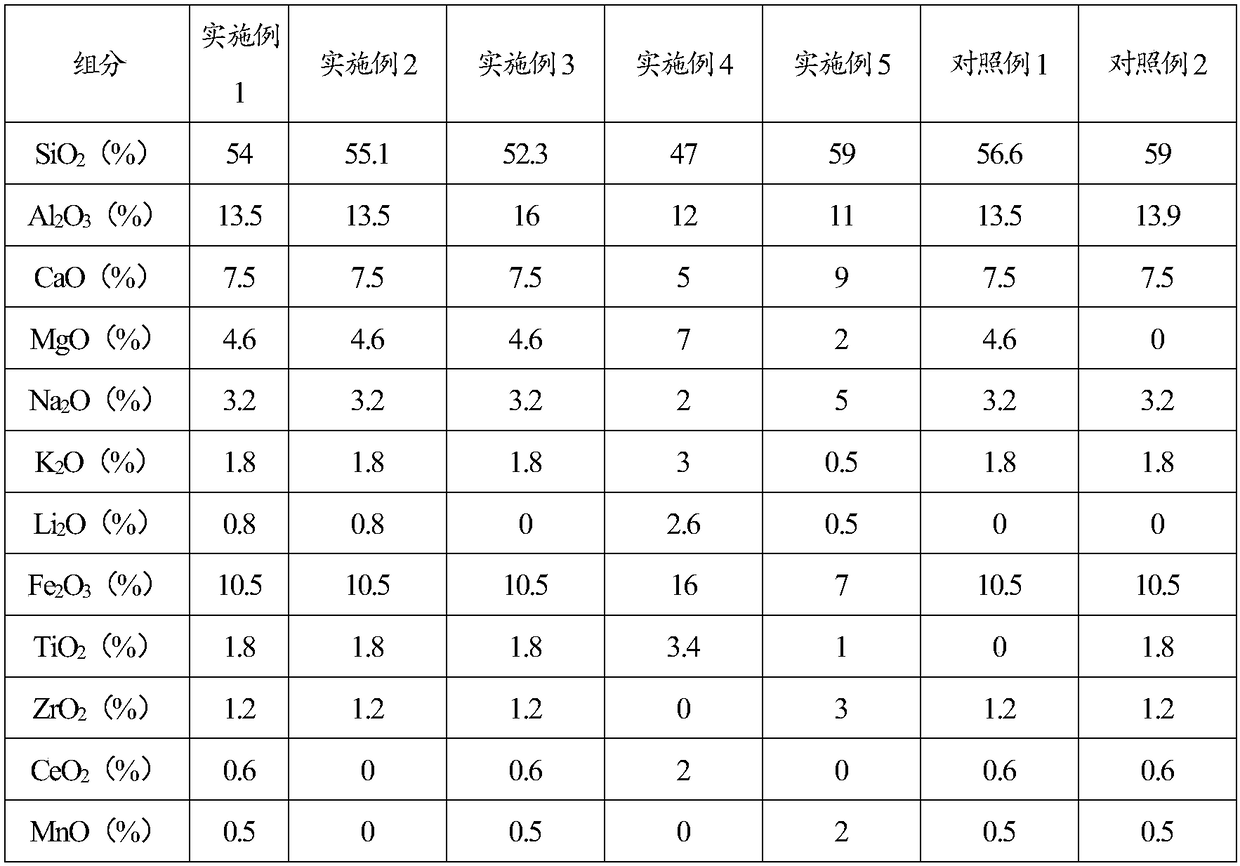

[0031] The batching method of basalt fiber includes: taking SiO 2 raw materials and detection of SiO 2 Content, Al 2 o 3 raw materials and detection of Al 2 o 3 content, CaO raw material and detect CaO content, MgO raw material and detect MgO content, Na 2 Feedstock for O and detection of Na 2 O content, K 2 Feedstock for O and detection of K 2 O content, Li 2 Feedstock for O and detection of Li 2 O content, Fe 2 o 3 Raw materials and detection of Fe 2 o 3 Content, ZrO 2 Raw materials and detection of ZrO 2 Content, CeO 2 raw materials and detect CeO 2 content and the raw material of MnO and detect the MnO content, counter-stirring and mixing to obtain the mineral mixture and detect the component content in the mineral mixture, and grind the mineral mixture into 200-300 mesh powder; in weight percentage, the The components in the mineral mixture are listed in Table 1.

[0032] Among them, the SiO 2 The raw material is selected from basalt, the Al 2 o 3 The...

Embodiment 6

[0040] The basalt fiber obtained by the batching method of the basalt fiber of the present invention has good performance, and the good performance of the basalt fiber obtained by the batching method of the basalt fiber of the present invention is specifically demonstrated through the following tests.

[0041] Performance test and method:

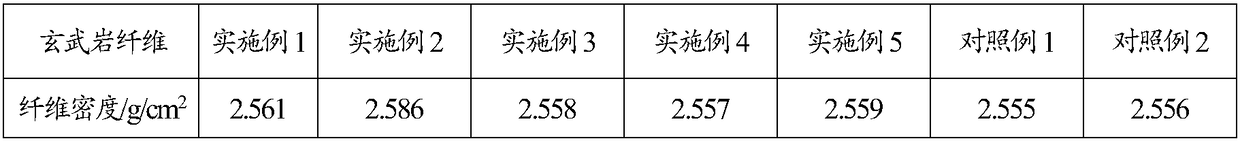

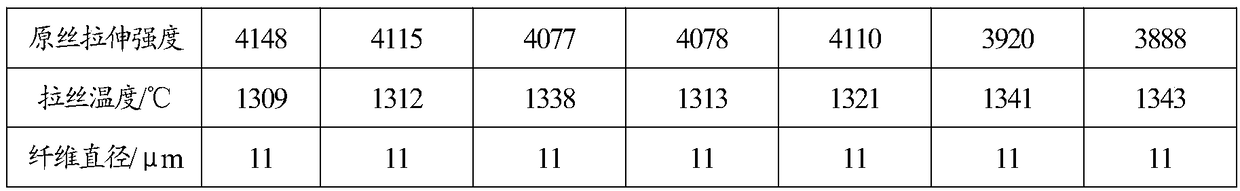

[0042] 1. Wire drawing operation temperature test

[0043] The viscosity of the basalt melt was tested with a high-temperature viscosity tester from Theta Company of the United States, and the temperature corresponding to the viscosity value of 103dPa.s was taken as the wire drawing temperature. The test results are shown in Table 2.

[0044] Table 2 Test results

[0045]

[0046]

[0047] Wherein, as can be seen from Table 2, the batching method of the basalt fiber of the present invention introduces Li 2 O, MgO, TiO 2 , ZrO 2 , CeO 2 And MnO make basalt fiber high strength, good stability, lower melting temperature, lower draw...

Embodiment 7~10

[0054] The difference between embodiment 7~10 and embodiment 1 is only:

[0055] The SiO 2 raw material, the Al 2 o 3 The raw material, the CaO raw material, the MgO raw material, the Na 2 O raw material, the K 2 The raw material of O, the Li 2 O raw material, the Fe 2 o 3 raw material, the TiO 2 The raw materials are shown in Table 4.

[0056] Table 4

[0057]

[0058]

[0059] After testing, the compounding method obtained in Examples 7-10 of the present invention uses various raw materials to hedge and mix, and the stability of the obtained basalt fiber is obviously better than that of the basalt fiber obtained by directly compounding only basalt as a single ore raw material on the market. sex. The invention adopts a variety of mineral mixtures, and the mineral mixture is prepared from various ores, so that the fluctuation range of the overall components is minimized, the stability is good, and the wire drawing performance is improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com