Self-cleaning type double-helical-ribbon differential velocity mixer

A double-screw belt, self-cleaning technology, applied in the direction of mixers, mixers with rotating stirring devices, mixer accessories, etc., can solve the problems of easy mixing dead angles, inability to completely replace, and lower mixing efficiency, so as to improve production Efficiency and product quality, small footprint and fast mixing times for results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

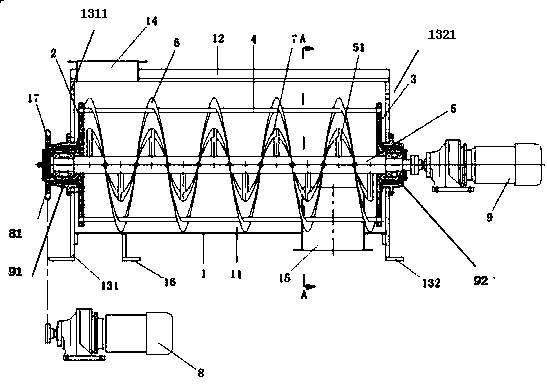

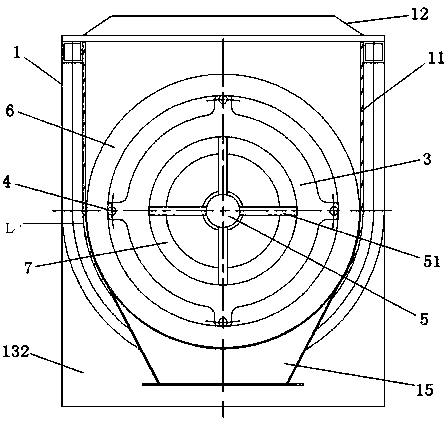

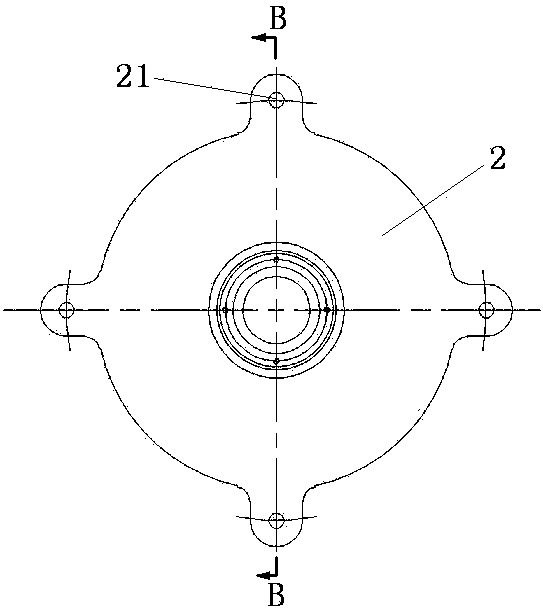

[0051] see figure 1 It is a schematic diagram of the structure of the present invention, figure 2 It is A-A sectional view of the present invention, image 3 It is a part diagram of the drive disc 2 of the present invention, Figure 4 for image 3 The B-B sectional view, Figure 5 for Figure 4 The C-C section view, Figure 6 It is part drawing and Figure 7 for Figure 6 The D-D sectional view.

[0052] Such as figure 1 As shown, a self-cleaning double-screw belt differential speed mixer includes a U-shaped casing 1, a motor-driven main shaft 5 located in the U-shaped casing 1, an inner screw belt 7 and an outer screw belt 6, wherein :

[0053] The U-shaped casing 1 is composed of a U-shaped wall 11, left and right side panels 131, 132 and a top cover 12, and a feed port 14 and a discharge port 15 are respectively arranged at two ends of the U-shaped casing 1. , the feed inlet 14 is arranged on the top cover 12, the outlet 15 is arranged at the bottom of the U-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com