Electrochemical-membrane separation water-treatment plant and treatment method thereof

A water treatment device and technology of a treatment device, applied in the field of water treatment, can solve the problems of membrane flux decrease, pH value easy to change, and precipitated particles clogging membrane pores, etc., to simplify the structure and composition, speed up the treatment speed, and slow down membrane fouling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

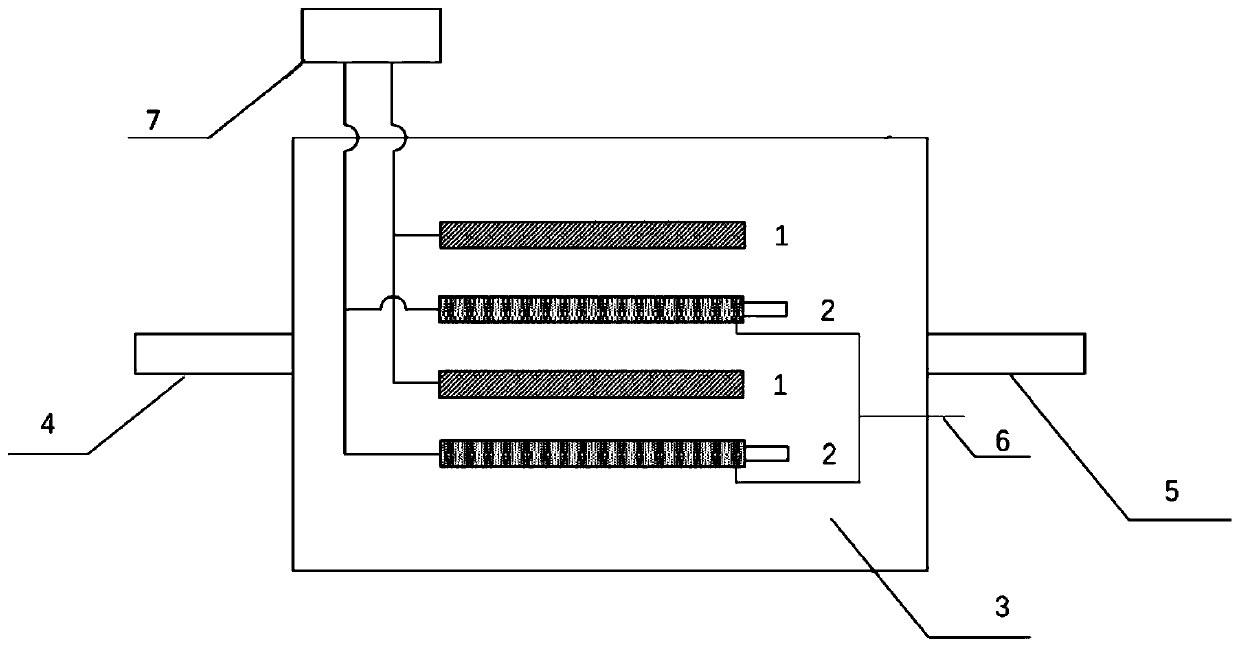

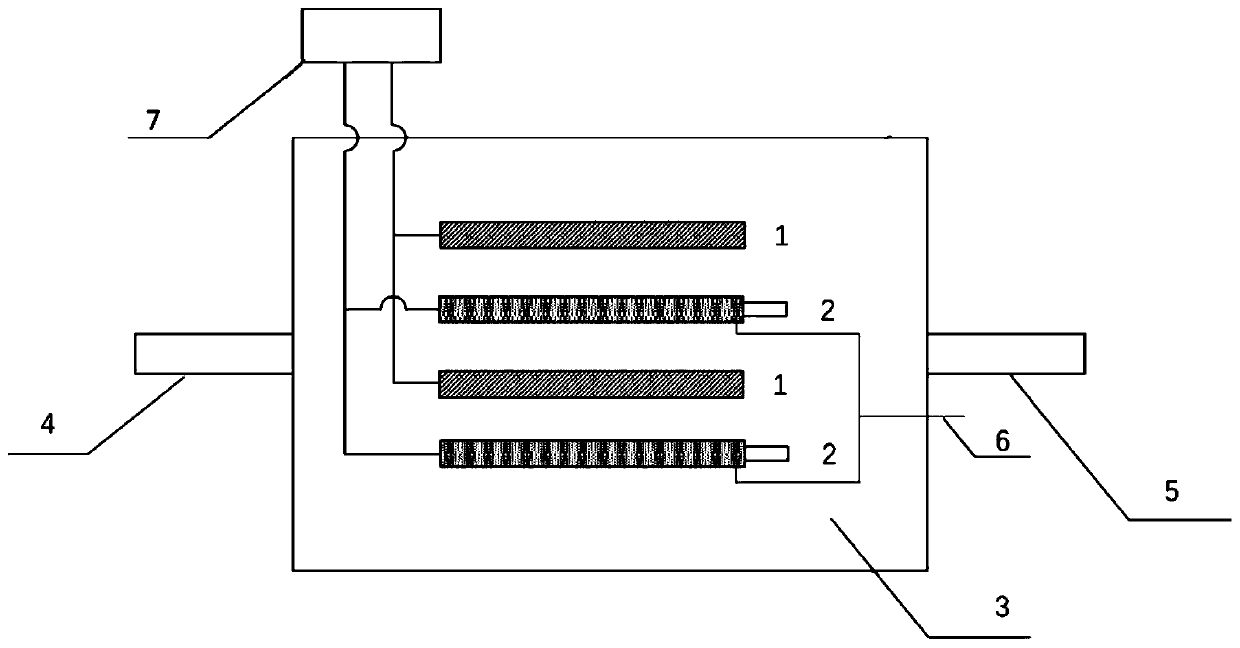

[0053] This embodiment provides an electrochemical-membrane separation water treatment device, the structural diagram of the device is as follows figure 1 As shown, a reaction pool 3 is included, and a membrane module 2 is arranged in the reaction pool 3. The membrane module 2 is a hollow fiber membrane module, and the membrane is a conductive membrane, and the conductive membrane material is a carbon material.

[0054] One side of the membrane assembly 2 is provided with an anode plate 1 parallel to the membrane assembly 2 , and the membrane assembly 2 is used as a cathode plate and the anode plate 1 is connected to an external power supply 7 .

[0055] The main body of the reaction tank 3 is provided with a water inlet 4 and a water outlet 6, and the outlet of the membrane module 2 is connected with the water outlet 6 on the main body of the reaction tank 3; There is a water return port 5.

[0056] There are two membrane components 2 and two anode plates 1, which are arrang...

Embodiment 2

[0059] This embodiment provides an electrochemical-membrane separation water treatment device, the device includes a reaction tank 3, a membrane module 2 is arranged in the reaction tank 3, the membrane module 2 is a plate-type membrane module, and the membrane therein is a conductive membrane, The conductive film material is a porous titanium plate.

[0060] One side of the membrane assembly 2 is provided with an anode plate 1 parallel to the membrane assembly 2 , and the membrane assembly 2 is used as a cathode plate and the anode plate 1 is connected to an external power supply 7 .

[0061] The main body of the reaction tank 3 is provided with a water inlet 4 and a water outlet 6, and the outlet of the membrane module 2 is connected with the water outlet 6 on the main body of the reaction tank 3; There is a water return port 5.

[0062] The membrane assembly 2 and the anode plate 1 are all one; an induction electrode is arranged between the membrane assembly 2 and the anod...

Embodiment 3

[0065] This embodiment provides an electrochemical-membrane separation water treatment device, the device includes a reaction tank 3, a membrane module 2 is arranged in the reaction tank 3, and an anode is arranged on one side of the membrane module 2 parallel to the membrane module 2 plate 1, the membrane assembly 2 is used as a cathode plate and the anode plate 1 is connected to an external power supply 7.

[0066] The main body of the reaction tank 3 is provided with a water inlet 4 and a water outlet 6, and the outlet of the membrane module 2 is connected with the water outlet 6 on the main body of the reaction tank 3; There is a water return port 5.

[0067] The membrane module 2 and the anode plate 1 are three, and are arranged alternately in the reaction cell 3; wherein in the anode plate 1, one is an aluminum electrode, and the other is an RuO electrode. 2 electrodes, the last one is IrO 2 -MnO 2 Composite electrode; the membrane module 2 is a hollow fiber membrane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com