Rare earth ion-doped PTR (Photo-Thermo-Refractive) laser glass ceramic and preparation method thereof

A technology of laser glass and rare earth ions, applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems of complex process, low thermal conductivity, poor thermal shock resistance, etc., and achieve the effect of simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A preparation method of rare earth ion-doped photothermographic laser glass ceramics, the specific steps are:

[0054] (1) According to the above formula 1 # Calculate the weight percentage of the glass from the molar composition in the glass, then weigh a total of 25kg of raw materials, and mix them uniformly in the mixing box.

[0055] (2) Add the prepared powder into an 11-liter platinum crucible in turn, heat and melt through a silicon carbide electric furnace, control the melting temperature at about 1250°C, and the melting time is 6 hours. During the melting process, use platinum leaf slurry to stir The device stirs the molten glass;

[0056] (3) After the cloudy glass liquid in step (2) eliminates bubbles and is fully stirred evenly, the glass cloudy liquid is melted, clarified, and homogenized by an optical glass melting method to form molten glass, and the melting temperature is 1420° C.; It is injected into a copper mold that has been preheated to 500°C to f...

Embodiment 2

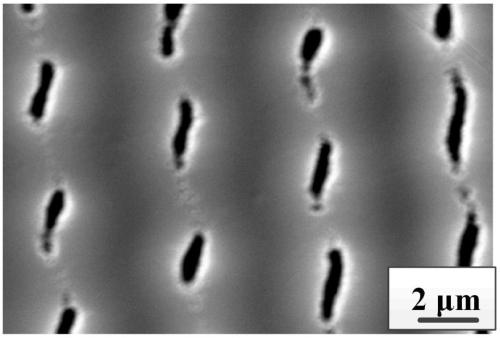

[0063] The difference from Embodiment 1 is that the writing optical power of the ultrashort pulse laser in step (6) is 200 mW. The SEM of the laser glass ceramics that the present embodiment makes is as figure 2 shown.

Embodiment 3

[0065] The difference from Embodiment 1 is that the writing optical power of the ultrashort pulse laser in step (6) is 300 mW. The SEM of the laser glass ceramics that the present embodiment makes is as image 3 shown.

[0066] right Figure 1~3 Statistical calculation of the size of the inner nanocrystalline particles shows that the average size of the nanoparticles is 175±50nm. It can be seen that the size of the nanoparticles has nothing to do with the writing optical power, but the density distribution of the nanocrystalline particles is related to the light focused in the PTR glass. The power density distribution is closely related. When the writing power of the ultrashort pulse laser was increased from 100mW to 200mW, the distribution area of nanocrystalline particles became wider and the density of nanocrystalline particles increased; when the writing power increased to 300mW, serious clustering of nanocrystalline particles occurred Phenomena eventually cluster int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com