Three-dimensional carbon material and preparation method thereof, as well as metal lithium composite electrode and preparation method thereof

A carbon material and lithium metal technology, applied in the field of nanomaterials, can solve the problems of lithium metal battery cycle stability and coulombic efficiency, few high current density and high surface capacity, and potential safety hazards, so as to achieve no dendrites, The effect of simple preparation method and high surface capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention also provides a method for preparing the above-mentioned three-dimensional carbon material, including: S1) immersing the sponge in the aqueous solution of the soluble catalyst precursor, and drying to obtain the immersed sponge; the soluble catalyst is a salt of an iron-based element Compound; S2) heating and insulating the soaked sponge in a protective atmosphere to obtain a three-dimensional carbon material.

[0037] Among them, the present invention does not have special restrictions on the source of all raw materials, as long as they are commercially available.

[0038] The sponge is a sponge well-known to those skilled in the art, and there is no special limitation. In the present invention, it is preferably polyether sponge, polyvinyl alcohol sponge, melamine sponge, polyurethane sponge, cotton fiber sponge, bamboo fiber sponge and wood fiber. One or more of the plain sponges. When melamine sponge or polyurethane sponge is used, the obtained three...

Embodiment 1

[0050] 1) Dissolve 0.15g nickel nitrate in 200ml ultrapure water.

[0051] 2) Dissolve 1g of urea in the above solution.

[0052] 3) The melamine sponge is completely immersed in the above solution, fully adsorbed for 12 hours and then dried at 60° C. to obtain the soaked sponge.

[0053] 4) Put the sponge into a quartz boat, and under the protection of argon, raise the temperature from room temperature to 800°C at a heating rate of 1°C per minute, and keep it for 2 hours to obtain a three-dimensional carbon material.

[0054] The melamine sponge is directly carbonized in argon according to step 4) to obtain a carbonized melamine sponge. Analyze the carbonized melamine sponge by scanning electron microscope to get its scanning electron microscope image, such as figure 1 Shown.

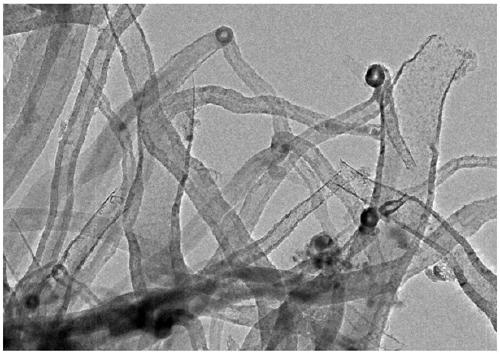

[0055] Use a scanning electron microscope to analyze the three-dimensional carbon material obtained in Example 1 to obtain a scanning electron microscope image, such as figure 2 Shown. From figure 2 It can b...

Embodiment 2

[0059] 1) Dissolve 0.15g nickel nitrate in 200ml ultrapure water.

[0060] 2) Dissolve 0.5 g of urea in the above solution.

[0061] 3) The melamine sponge is completely immersed in the above solution, fully adsorbed for 12 hours and then dried at 60° C. to obtain the soaked sponge.

[0062] 4) Put the sponge into a quartz boat, and under the protection of argon, raise the temperature from room temperature to 800°C at a heating rate of 1°C per minute, and keep it for 2 hours to obtain a three-dimensional carbon material.

[0063] Analyze the three-dimensional carbon material obtained in Example 2 with a scanning electron microscope to obtain a scanning electron microscope image, such as Figure 5 Shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com