Combination electrode of transition metal modified TiO2-MOFs membrane and preparation method and application of combination electrode

A composite electrode and transition metal technology, applied in the field of water treatment, can solve the problem of limited ability to remove such pollutants, and achieve the effect of improving photocatalytic activity, stable properties, stability and photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1 A kind of transition metal modified TiO 2 - Preparation of composite electrode of MOFs membrane

[0045] 1) Preparation of MOFs membrane material:

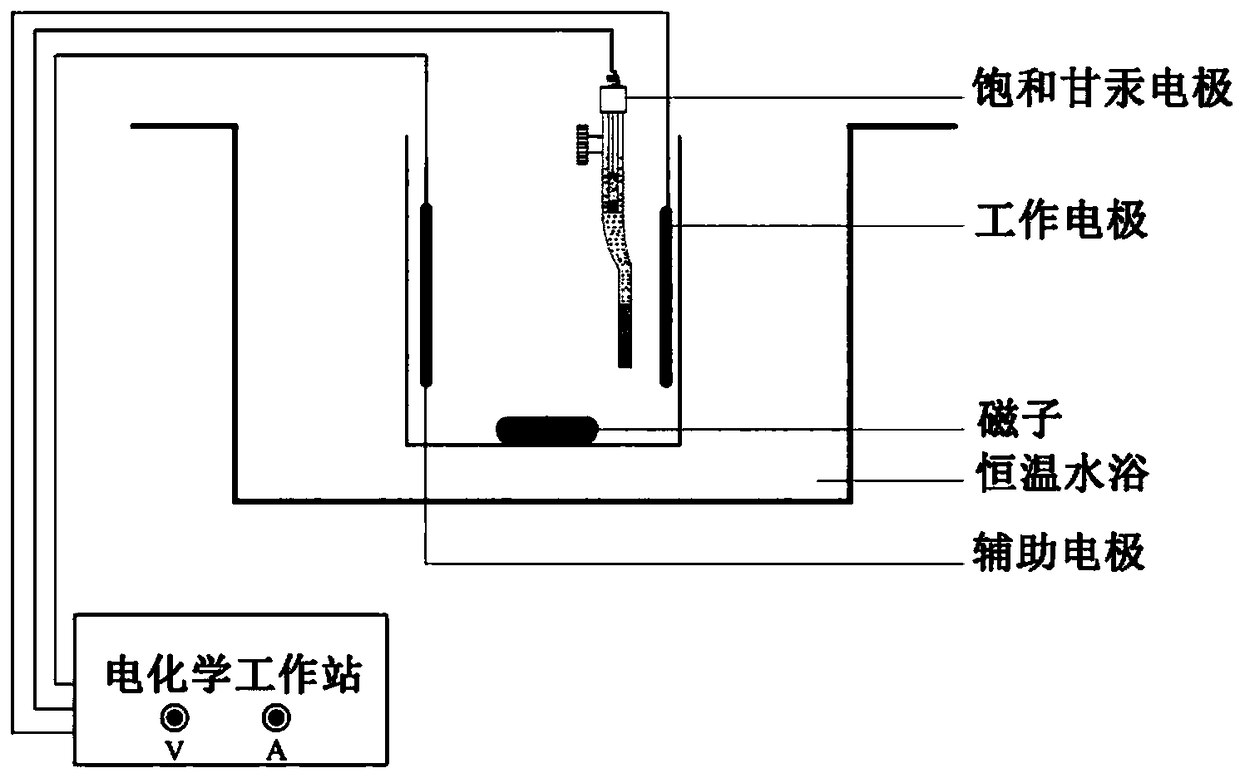

[0046] The auxiliary electrode is a platinum wire mesh, the reference electrode is a saturated calomel electrode, and the working electrode is a pure copper mesh with a diameter of 5.0 cm and an aperture of 5 mesh. After ultrasonic cleaning with pure water, use degreasing liquid (10g / L NaOH, 70g / L NaOH 2 CO 3 , 40g / L Na 3 PO 4 12H 2 O and 4g / L Na 2 SiO 3 ) to remove surface oil stains, fully soaked in 100mL of terephthalic acid solution, then electrodeposited (cathode current density 10 mA / cm 2 , solution temperature 30°C, pH 3, stirring rate 200rpm and deposition time 30min) to obtain MOFs film;

[0047] 2) TiO 2 - Preparation of MOFs film: After adding the MOFs film obtained in step 1) to the ethanol solvent, after the wetting is sufficient, slowly add 5 mL of tetrabutyl titanate (Ti(OBu) 4 ), ultr...

Embodiment 2

[0049] Example 2 Transition metal modified TiO 2 - Preparation of MOFs membrane composite electrode

[0050] 1) Preparation of MOFs membrane material:

[0051] The auxiliary electrode is a platinum wire mesh, the reference electrode is a saturated calomel electrode, and the working electrode is a pure copper mesh with a diameter of 5.0 cm and an aperture of 8 mesh. After ultrasonic cleaning with pure water, use degreasing liquid (11g / L NaOH, 70g / L NaOH 2 CO 3 , 70g / L Na 3 PO 4 12H 2 O and 8g / L Na 2 SiO 3 ) to remove surface oil stains, fully soak in 150mL tereoxalic acid solution, and then conduct electrodeposition (cathode current density 55 mA / cm 2 , solution temperature 45°C, pH 4, stirring rate 400rpm and deposition time 60min) to obtain MOFs film;

[0052] 2) TiO 2 - Preparation of MOFs film: After adding the MOFs film obtained in step 1) into the ethanol solvent, after the wetting is sufficient, slowly add 10 mL of tetrabutyl titanate (Ti(OBu) 4 ), ultrasonica...

Embodiment 3

[0054] Example 3 Transition metal modified TiO 2 - Preparation of MOFs membrane composite electrode

[0055] 1) Preparation of MOFs membrane material:

[0056] The auxiliary electrode is a platinum wire mesh, the reference electrode is a saturated calomel electrode, and the working electrode is a pure copper mesh with a diameter of 5.0 cm and an aperture of 20 mesh. Use degreasing liquid (16g / L NaOH, 100g / L NaOH) after ultrasonic cleaning with pure water 2 CO 3 , 100g / L Na 3 PO 4 12H 2 O and 12g / L Na 2 SiO 3 ) to remove surface oil stains, fully soak in 100mL of succinic acid solution, and then conduct electrodeposition (cathode current density 100 mA / cm 2 , solution temperature 60°C, pH 6, stirring rate 600rpm and deposition time 90min) to obtain MOFs film;

[0057] 2) TiO 2 - Preparation of MOFs film: After adding the MOFs film obtained in step 1) into the ethanol solvent, after the wetting is sufficient, slowly add 4 mL of tetrabutyl titanate (Ti(OBu) 4 ), ultras...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com