Preparation method of high toughness PE hollow wall twined pipe based on red mud modification

A preparation process and high toughness technology, which is applied in the direction of tubular articles, household utensils, applications, etc., to achieve the effects of environmental protection of the preparation process, improved compatibility, and excellent waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

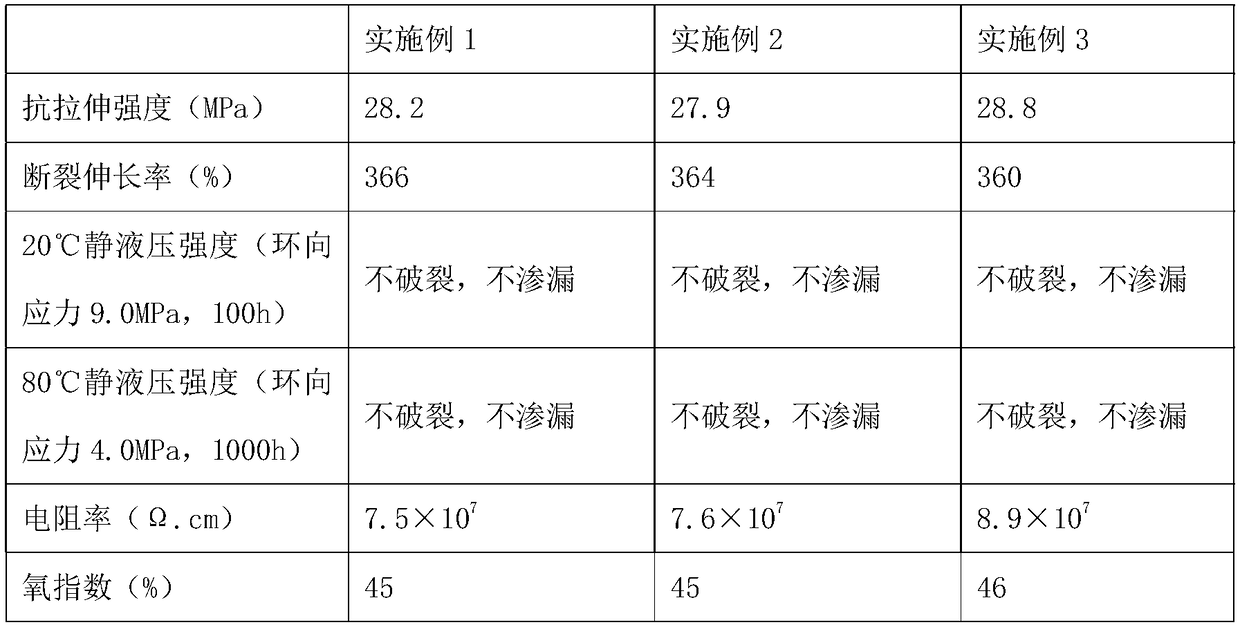

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the embodiments.

[0028] The invention discloses a preparation process of a high-toughness PE hollow-wall wound pipe based on red mud modification, which comprises the following steps:

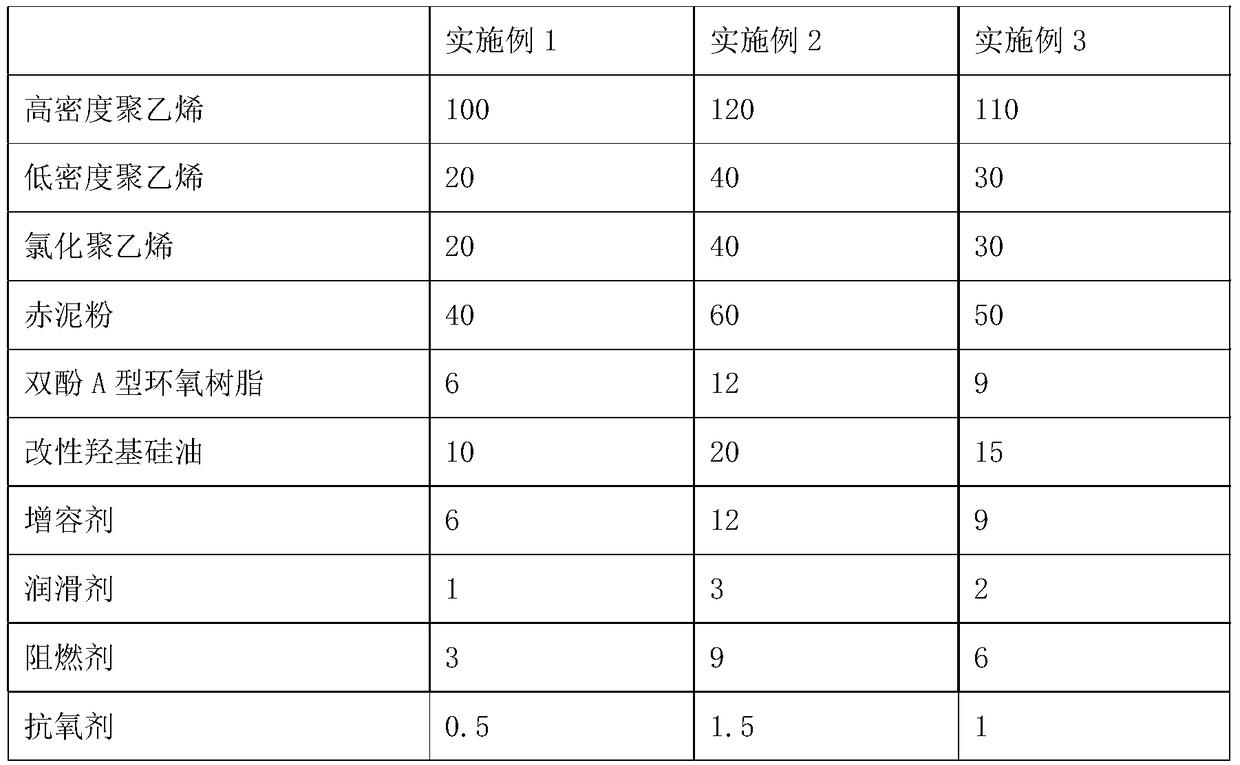

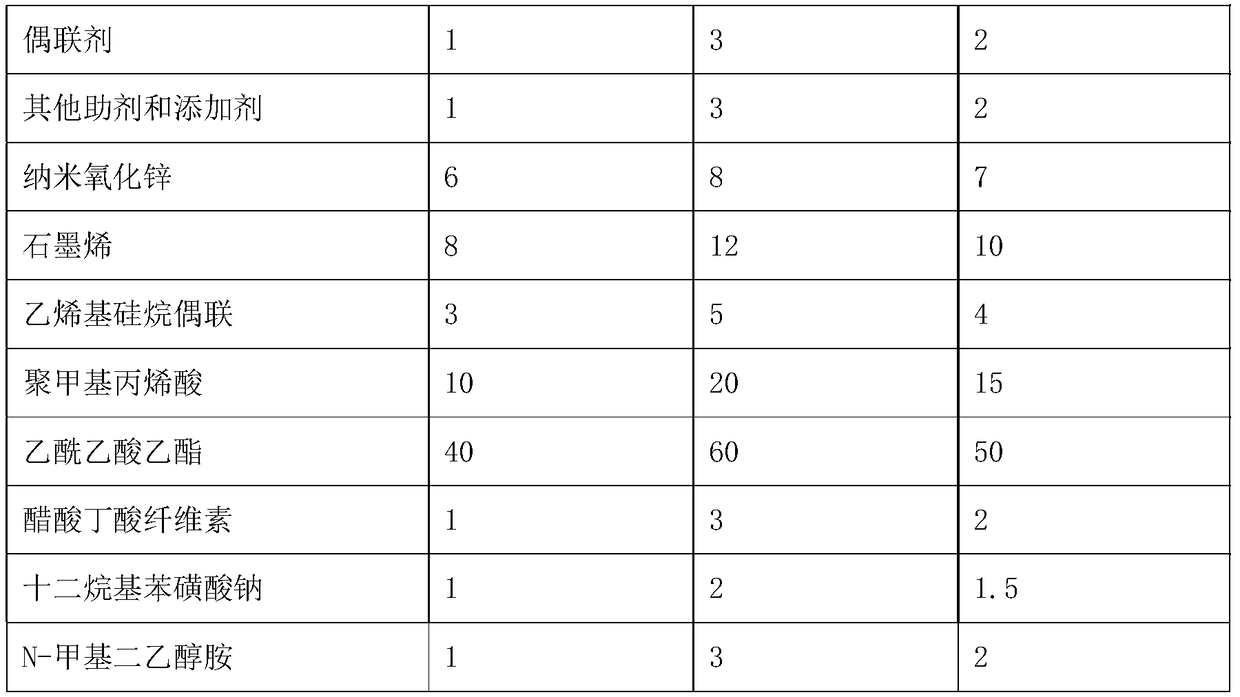

[0029] (1) By weight fraction, weigh polyethylene mixed resin, red mud powder, bisphenol A epoxy resin, modified hydroxyl silicone oil, nano zinc oxide, graphene, compatibilizer, lubricant, flame retardant , antioxidant, coupling agent, polymethacrylic acid, ethyl acetoacetate, vinyl silane coupling agent, cellulose acetate butyrate, sodium dodecylbenzenesulfonate, N-methyldiethanolamine, other additives agents and additives;

[0030] (2) Add polymethacrylic acid to ethyl acetoacetate to prepare solution A, stir with a stirrer for 2-3h, add vinyl silane coupling agent, nano-zinc oxide and graphene powder to the above-mentioned solution A in sequence, and ultrasonically 30-40min, add cellulose acetate butyrate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com