A kind of preparation method of molybdenum metal grid

A molybdenum metal and grid technology is applied in the field of preparation of molybdenum metal grid, which can solve the problems of low plasticity and poor forming performance, and achieve the effects of dense and uniform particles, increased density and good fluidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

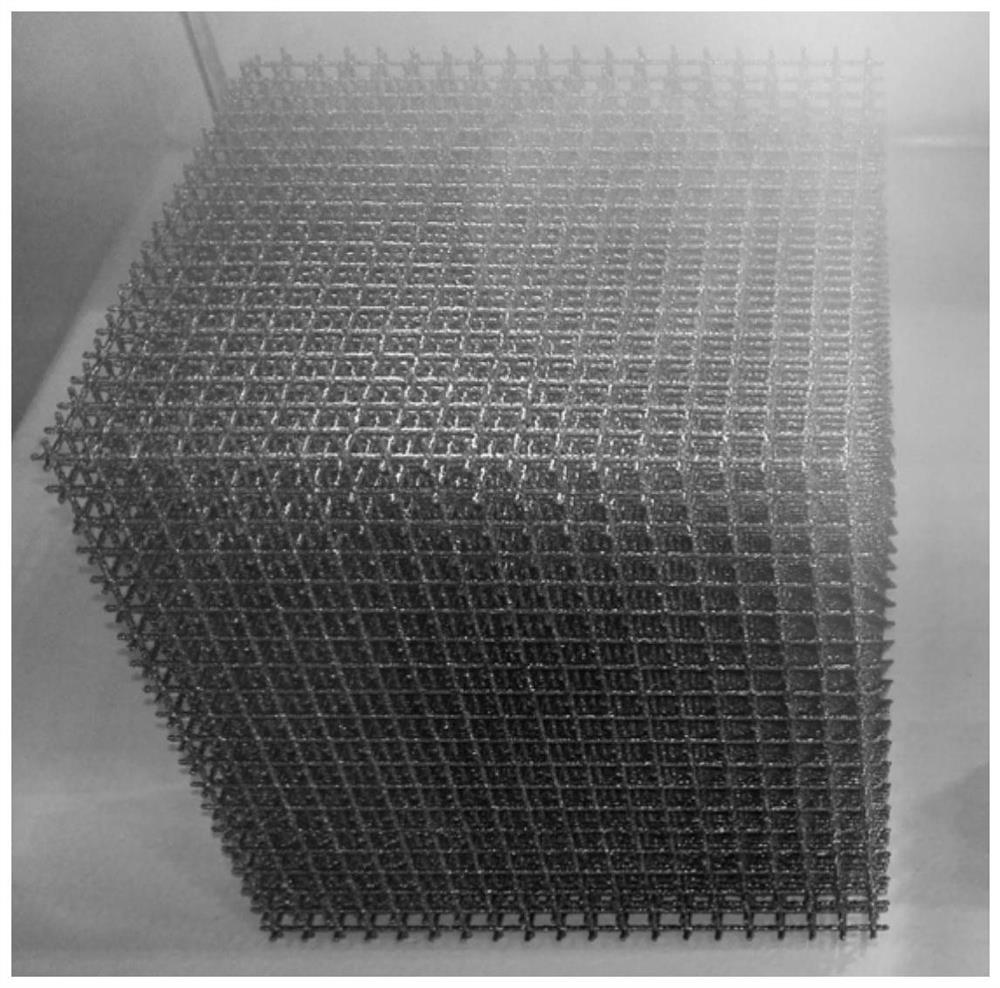

Image

Examples

Embodiment 1

[0035] The preparation method of the present embodiment comprises the following steps:

[0036] Step 1, preparation of molybdenum rods:

[0037] Step 101, put the molybdenum powder into the prefabricated rubber sleeve mold, seal it with a rubber stopper after vibration treatment, and then place it in the pressure chamber of the cold isostatic press for 12 minutes of cold isostatic pressing under the condition of a pressure of 180 MPa, Molybdenum rod biscuit is obtained after demolding; the particle size of the molybdenum powder is 3.6 μm, the mass purity of the molybdenum powder is 99.97%, the mass content of oxygen is 1100ppm, and the tap density of the molybdenum powder is 3.5g / cm 3 ;

[0038] Step 102, trimming the outer surface of the molybdenum rod blank obtained in step 101 to remove its corner burrs and surface defects, and then placing it in a vacuum furnace for high-temperature sintering treatment to obtain a molybdenum rod semi-finished product; the specific process...

Embodiment 2

[0048] The preparation method of the present embodiment comprises the following steps:

[0049] Step 1, preparation of molybdenum rods:

[0050] Step 101, put the molybdenum powder into the prefabricated rubber sleeve mold, seal it with a rubber stopper after vibration treatment, and then place it in the pressure chamber of the cold isostatic press for 10 minutes of cold isostatic pressing under the condition of a pressure of 150 MPa, The molybdenum rod biscuit is obtained after demolding; the particle size of the molybdenum powder is 2.0 μm, the mass purity of the molybdenum powder is 99.95%, the mass content of oxygen is 1500 ppm, and the tap density of the molybdenum powder is 2.0 g / cm 3 ;

[0051] Step 102, trimming the outer surface of the molybdenum rod blank obtained in step 101 to remove its corner burrs and surface defects, and then placing it in a vacuum furnace for high-temperature sintering treatment to obtain a molybdenum rod semi-finished product; the specific p...

Embodiment 3

[0061] The preparation method of the present embodiment comprises the following steps:

[0062] Step 1, preparation of molybdenum rods:

[0063] Step 101, put the molybdenum powder into the prefabricated rubber sleeve mold, seal it with a rubber stopper after vibration treatment, and then place it in the pressure chamber of the cold isostatic press for 15 minutes of cold isostatic pressing under the condition of 230 MPa After cold isostatic pressing, molybdenum rod green body is obtained after demoulding; the particle size of the molybdenum powder is 4.5 μm, the mass purity of the molybdenum powder is 99.97%, the mass content of oxygen is 1200ppm, and the tap density of the molybdenum powder is 6.0 g / cm 3 ;

[0064] Step 102, trimming the outer surface of the molybdenum rod blank obtained in step 101 to remove its corner burrs and surface defects, and then placing it in a vacuum furnace for high-temperature sintering treatment to obtain a molybdenum rod semi-finished product...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com