Method for preparing composite silicon-based aerogel by using iron tailings as raw material

A composite technology of iron tailings, applied in the direction of airgel preparation, chemical instruments and methods, colloid chemistry, etc., can solve the problems of low safety factor, restriction of industrial production, harsh conditions, etc., to reduce environmental impact, improve Recycling rate, effect of enhancing structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

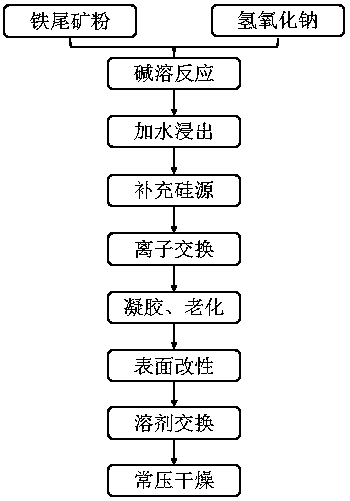

[0027] A method for preparing composite silicon-based airgel with iron tailings as raw material, comprising the following steps:

[0028] 1) The iron tailings are crushed, and the iron tailings powder with a mesh number of more than 100 meshes is mixed with sodium hydroxide particles at a mass ratio of 1:1.4, and heated to 400°C in a muffle furnace for 2 hours for alkali dissolution reaction. After cooling to room temperature, mix with water at a solid-to-liquid ratio of 1:3 (that is, mix the whole mixture of cooled iron tailings and sodium hydroxide with water, the following are the same, and the unit of solid-to-liquid ratio is g / mL). Heat and stir at 70°C for 20 hours, collect the filtrate after filtration, and obtain a crude silicon solution;

[0029] 2) The crude silicon solution obtained in step 1) is mixed evenly with the water glass solution at a volume ratio of 6:1 (the water glass solution is added to supplement the silicon source), and the ion exchange is carried ou...

Embodiment 2

[0036] A method for preparing composite silicon-based airgel with iron tailings as raw material, comprising the following steps:

[0037] 1) The iron tailings are crushed, and the iron tailings powder with a mesh number of more than 100 meshes is mixed with sodium hydroxide particles at a mass ratio of 1:2.2, and heated to 500°C in a muffle furnace for 3 hours for alkali dissolution reaction. After cooling to room temperature, mix it with water at a solid-liquid ratio of 1:6 (the unit of solid-liquid ratio is g / mL), heat and stir at 85°C for 24 hours, collect the filtrate after filtration, and obtain a crude silicon solution;

[0038] 2) The crude silicon solution obtained in step 1) is mixed evenly with the water glass solution at a volume ratio of 8:1 (the water glass solution is added to supplement the silicon source), and the ion exchange is carried out through the D-62 macroporous strongly acidic styrene-based cation exchange resin , add dropwise 0.5mol / L ammonia solution...

Embodiment 3

[0042] A method for preparing composite silicon-based airgel with iron tailings as raw material, comprising the following steps:

[0043] 1) The iron tailings are crushed, and the iron tailings powder with a mesh number of more than 100 meshes is mixed with sodium hydroxide particles at a mass ratio of 1:1.8, and heated to 450°C in a muffle furnace for 2.5 hours for alkali dissolution reaction , after cooling to room temperature, mix it with water according to the solid-liquid ratio of 1:5 (the unit of solid-liquid ratio is g / mL), heat and stir at 80°C for 23h, collect the filtrate after filtration, and obtain a crude silicon solution;

[0044] 2) The crude silicon solution obtained in step 1) is mixed evenly with the water glass solution at a volume ratio of 7:1 (the water glass solution is added to supplement the silicon source), and the ion exchange is carried out through the D-62 macroporous strongly acidic styrene-based cation exchange resin , add dropwise 0.4mol / L ammoni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com