Preparation method of chelate adsorbent

A technology of chelating adsorbents and organic solvents, applied in the field of materials, can solve problems such as poor economy, property loss, landslides and debris flows, and achieve good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation of graft monomer EDTAD, its preparation steps are as follows:

[0030] Suspend 18g of EDTA (acid) in 31ml of anhydrous pyridine, then add 25ml of anhydride under nitrogen protection, and stir at 65°C for a certain period of time. According to this, the product is cooled and filtered under a stable nitrogen flow, washed with 200ml of anhydrous acetic anhydride and anhydrous acetic anhydride, and finally dried in a vacuum oven at 50-60°C to obtain the grafted monomer EDTAD. The EDTAD obtained by the reaction was tested by infrared.

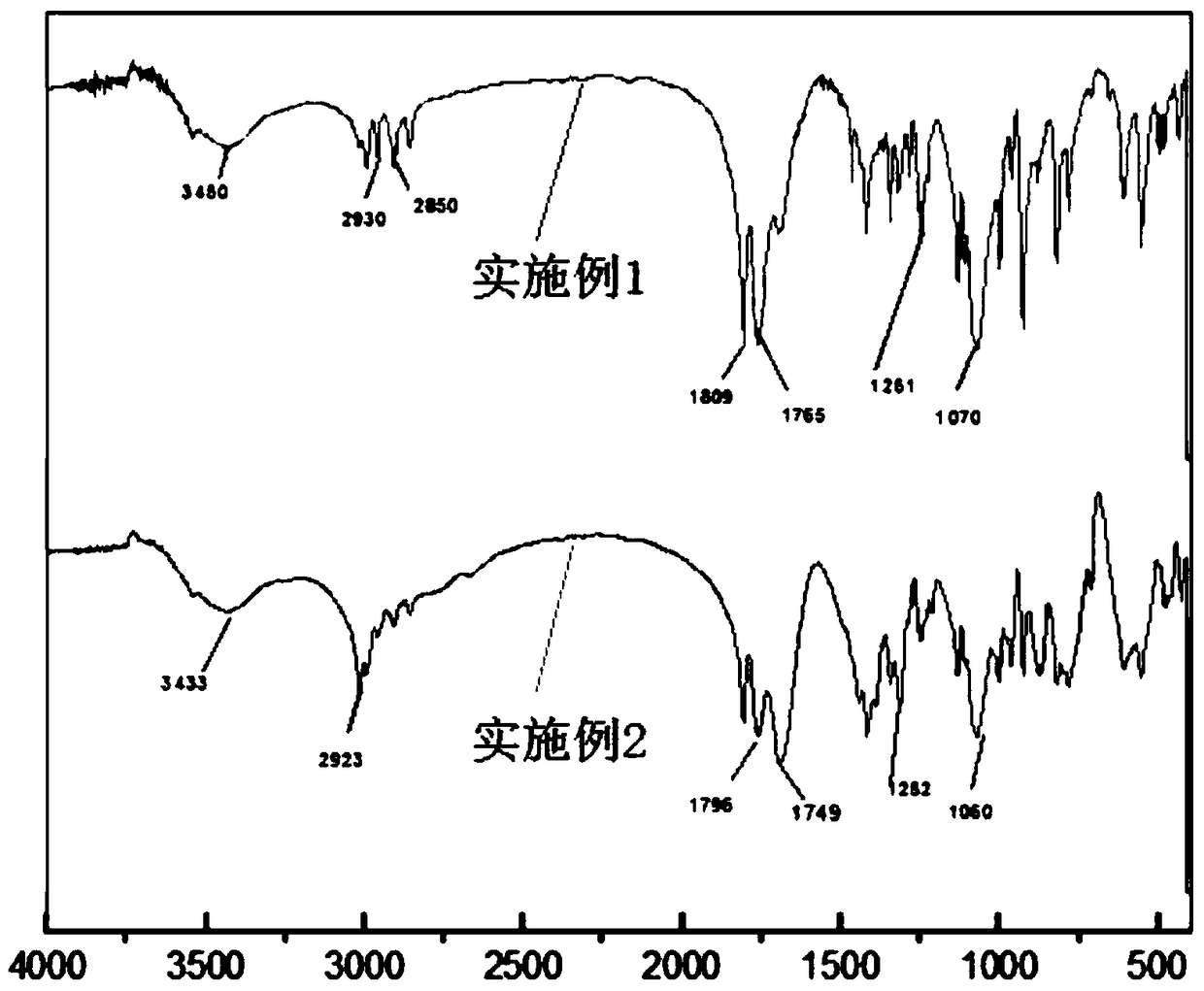

[0031] The infrared spectrum of the present embodiment gained EDTAD sees figure 1 , in the infrared spectrum of EDTAD at 1809cm -1 and 1765cm -1 Absorption characteristic peaks appear and the low-frequency peak is slightly stronger than the high-frequency peak, which are two characteristic absorption peaks of the C=O stretching vibration absorption of the acid anhydride. These are the characteristic peaks of the cyclic anhy...

Embodiment 2

[0033] Suspend 30g of EDTA (acid) in 50m of anhydrous pyridine, then add 50ml of anhydride under nitrogen protection, and stir at 65°C for a certain period of time. According to this, the product was cooled and filtered under a stable nitrogen flow, washed with 200ml of anhydride and ether, and finally dried in a vacuum oven at 50-60°C to obtain the grafted monomer EDTAD. The EDTAD obtained by the reaction was tested by infrared.

[0034] The infrared spectrum of the present embodiment gained EDTAD sees figure 1 , in the infrared spectrum of EDTAD at 1796cm -1 and 1749cm -1 Absorption characteristic peaks appear and the low frequency peak is slightly stronger than the high frequency peak, which are two characteristic absorption peaks of the C=O stretching vibration absorption of the acid anhydride. These are the characteristic peaks of the cyclic anhydride. at 1252cm -1 The stretching vibration peak at is the C-O-C stretching vibration peak of the cyclic anhydride, at 1060...

Embodiment 3

[0036] 1g chitosan monomer is completely dissolved with 2ml glacial acetic acid, after a certain period of time, after dissolving, solution is added in 50mlN, in the N-dimethylformamide, then add 1g embodiment 1 gained EDTAD grafting monomer, and at 65 Polymerization reaction was carried out at ℃ and in a nitrogen-enclosed environment until the reaction was complete. After the reaction was completed, it was washed with 50ml of N,N-dimethylformamide and filtered, then washed with 100ml of distilled water for centrifugation, and then washed with 100ml of saturated sodium bicarbonate solution for centrifugation. , then wash with 100ml of distilled water and carry out centrifugation, finally wash with 50ml of 95% ethanol and carry out centrifugation, place it in a vacuum oven and dry it at 70°C to obtain the chitosan graft of the present invention.

[0037] The chitosan graft obtained is placed in the calcium solution of configuration and adsorbed for 2h, and the solution after ads...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com