Combined strengthening treatment method for plasma immersion ion implantation and deposition on surfaces of spallation target balls

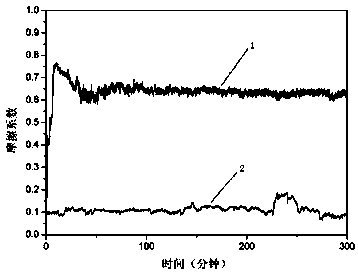

An immersion ion implantation and plasma technology, which is applied in the field of powder metallurgy, can solve the problems of insufficient bonding force of the film base, low bombardment strength of the target ball surface, and easy peeling of the film layer, and achieves low friction coefficient and good wear resistance. , The effect of improving hardness and bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A metal plasma immersion ion implantation and deposition compound strengthening treatment method on the surface of a spallation target ball, the strengthening treatment method comprising the following steps:

[0041] (1) The spallation target sphere is ultrasonically cleaned twice in an ethanol solution with a purity of 99.9%;

[0042] (2) Place the spallation target ball on the vacuum target table, vacuumize and start the sputtering cleaning equipment for argon ion sputtering cleaning, the flow rate of argon gas is controlled at 15 sccm, and the working pressure is 1.0×10 -1 Pa, the bias amplitude is 2 kV, the bias pulse width is 80 μs, the pulse frequency is 75 Hz, the RF power is 200 W, and the processing time is 40 min;

[0043] (3) Titanium ions are purely implanted into the spallation target ball. The titanium plasma is generated from cast titanium with a purity of 99.99% as the cathode through a magnetic filter pulse cathode arc source. The working pressure of t...

Embodiment 2

[0054] A metal plasma immersion ion implantation and deposition compound strengthening treatment method on the surface of a spallation target ball, the strengthening treatment method comprising the following steps:

[0055] (1) The spallation target sphere is ultrasonically cleaned twice in an ethanol solution with a purity of 99.9%;

[0056] (2) Place the spallation target ball on the vacuum target table, vacuumize and start the sputtering cleaning equipment for argon ion sputtering cleaning, the flow rate of argon gas is controlled at 30 sccm, and the working pressure is 6.0×10 -1 Pa, the bias amplitude is 3 kV, the bias pulse width is 120 μs, the pulse frequency is 90 Hz, the RF power is 400 W, and the processing time is 50 min;

[0057] (3) Pure titanium ion implantation is carried out on the spallation target ball. The titanium plasma is generated by cast titanium with a purity of 99.99% as the cathode through the magnetic filter pulse cathode arc source. The working pre...

Embodiment 3

[0067] A metal plasma immersion ion implantation and deposition compound strengthening treatment method on the surface of a spallation target ball, the strengthening treatment method comprising the following steps:

[0068] (1) The spallation target sphere is ultrasonically cleaned twice in an ethanol solution with a purity of 99.9%;

[0069] (2) Place the spallation target ball on the vacuum target table, vacuumize and start the sputtering cleaning equipment for argon ion sputtering cleaning, the argon gas flow rate is controlled at 25 sccm, and the working pressure is 3.0×10 -1 Pa, the bias amplitude is 2.5 kV, the bias pulse width is 100 μs, the pulse frequency is 80 Hz, the RF power is 300 W, and the processing time is 45 min;

[0070] (3) Pure titanium ion implantation is performed on the spallation target ball. The titanium plasma is generated by the cast titanium with a purity of 99.99% as the cathode through the magnetic filter pulse cathode arc source. The working pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com