Emulsion for cathodic electrophoretic paint and preparation method thereof, cathodic electrophoretic paint and preparation method thereof

A cathodic electrophoretic paint and emulsion technology, which is applied in the field of paint, can solve the problems of low reaction efficiency between alcohol hydroxyl groups and epoxy groups, high charge density of cathodic electrophoretic paint, and further improvement in throwing power, so as to achieve a smooth and smooth appearance of the paint film. Easy to operate on a large scale and improve the effect of throwing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

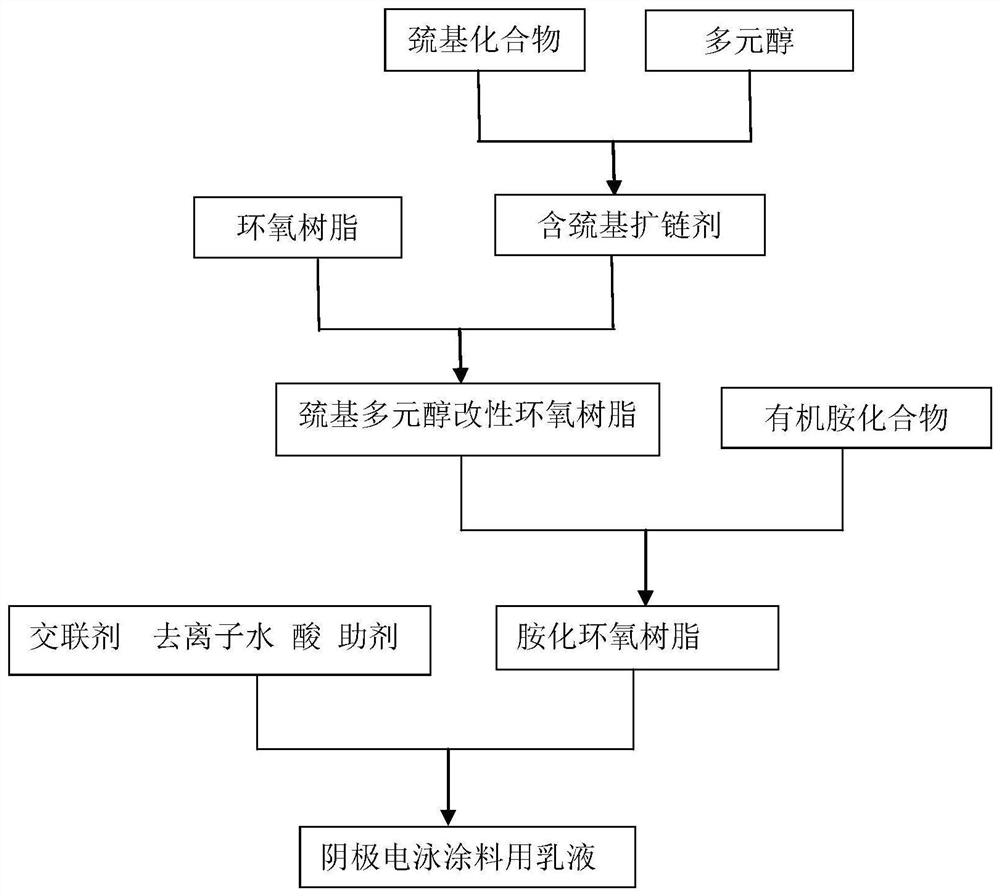

[0058] The preparation method of the cathodic electrophoretic coating emulsion of the present embodiment, such as figure 1 shown, including the following steps:

[0059] 1) Preparation of chain extender

[0060]

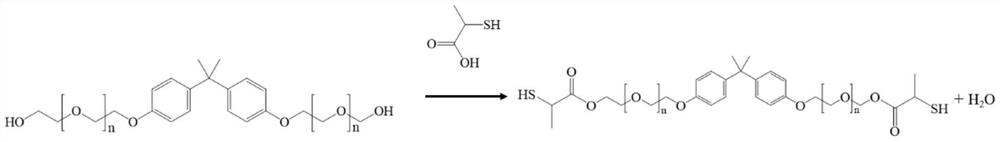

[0061] Drop into 360 parts of bisphenol A type polyoxyethylene ether (average molecular weight 450), 106 parts of thiolactic acid, 160 parts of di Toluene, control the speed of the stirring device to 400rpm, heat to 100°C; after mixing evenly, add 0.5 parts of dibutyltin oxide catalyst, 0.5 parts of SO 4 2- / TiO 2 Solid super acid catalyst, heat up to 160°C and start to reflux, continue to heat up to 170°C, and keep it at 170°C for 7 hours; cool down to 160°C and feed nitrogen to remove the remaining xylene, keep it at 160°C for 1 hour, and then continue Feed nitrogen to cool down. When the temperature drops below 140°C, stop feeding nitrogen and continue to cool down. When the acid value is less than 10mgKOH / g, the reaction is complete and the chain extender ...

Embodiment 2

[0079] The preparation method of the cathodic electrophoretic coating emulsion of the present embodiment may further comprise the steps:

[0080] 1) Drop into 530 parts of polycaprolactone glycol (PCL-205), 284 parts of 3-mercaptoisobutyric acid, 150 parts of xylene, control the speed of the stirring device at 600rpm, heat to 100°C; after mixing evenly, add 0.5 parts of tetraphenyltin catalyst and 0.5 parts of SO 4 2- / ZrO 2 Solid super acid catalyst, heat up to 170°C and start to reflux, continue to heat up to 200°C, and keep it at 200°C for 8 hours; cool down to 150°C and feed nitrogen to remove the remaining xylene, keep it at 150°C for 2 hours, and then continue Feed nitrogen to cool down. When the temperature drops below 140°C, stop feeding nitrogen and continue to cool down. When the acid value is less than 10mgKOH / g, the reaction is complete and the chain extender is obtained;

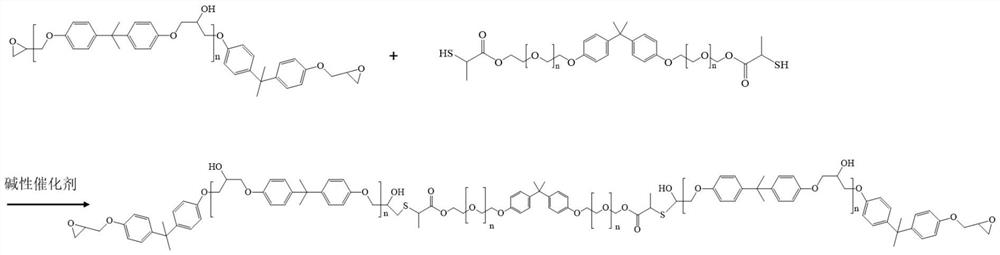

[0081] 2) Under nitrogen protection, put 203 parts of chain extender and 475 parts of epo...

Embodiment 3

[0088] The preparation method of the cathodic electrophoretic coating emulsion of the present embodiment may further comprise the steps:

[0089] 1) Drop into 850 parts of polytetrahydrofuran diol (average molecular weight 850), 310 parts of 2-mercaptonicotinic acid, 150 parts of dimethylformin in the reactor with heating and stirring device, water separating device, condensation reflux device and inert gas protection device Dibutyltin dilaurate catalyst and 0.5 part of SO 4 2- / Fe 2 o 3 Solid superacid catalyst, heat up to 170°C and start reflux, continue to heat up to 190°C, keep at 190°C for 7 hours; cool down to 160°C, blow nitrogen to remove the remaining dimethylformamide, and keep at 160°C for 1 hour , and then continue to feed nitrogen to cool down. When the temperature drops below 140°C, stop feeding nitrogen and continue to cool down. When the acid value is less than 10mgKOH / g, the reaction is complete and a chain extender is obtained;

[0090] 2) Under the prote...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com