Core-shell structure compound prepared by fuse salt method and preparation method thereof

A technology of core-shell structure and molten salt method, which is applied in the field of materials, can solve the problems of high cost, cumbersome process, and low crystallinity, and achieve the effect of excellent material performance, simple preparation process, and regular crystal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1: Porous CuO@MnO 2 preparation of

[0029] (1) Weigh 150mg (CH3COO) 2 ·Cu·(H 2 O), 3g NaNO 3 , 150 mg of alkylphenol polyoxyethylene ether was mixed and ground evenly, placed in a tube furnace, heated to 350°C for calcination, and kept for 2 hours. After it was cooled to room temperature, the sample was taken out and placed in a centrifuge tube, and washed with distilled water for several times. Once, NaNO3 was removed and dried at 80°C to obtain the precursor target product CuO.

[0030] (2) Weigh 50mg CuO and 50mg KMnO 4 and 3g Na 2 SO 4 Grinding, calcination at 300°C for 2 hours, after cooling to room temperature, take out the sample and place it in a centrifuge tube, add distilled water and wash it several times by centrifugation to remove Na 2 SO 4 , dried at 80°C to obtain the target product CuO@MnO 2 .

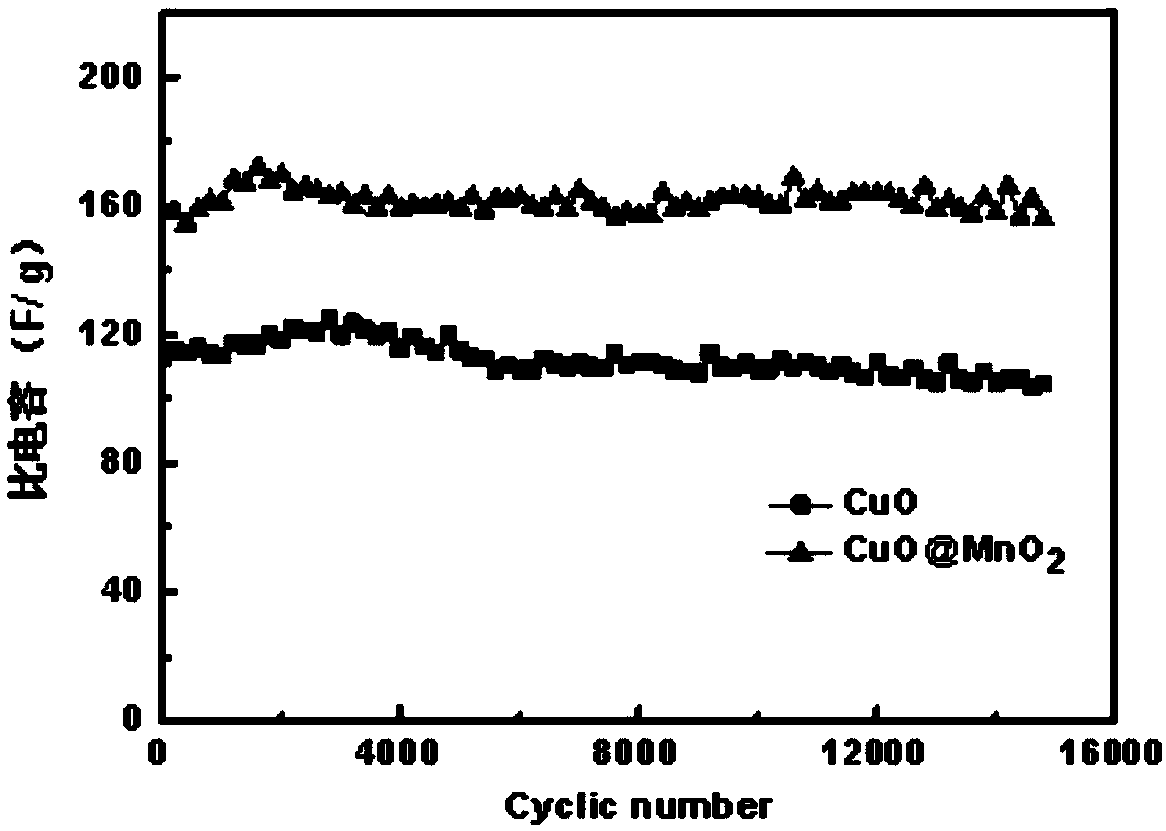

[0031] From figure 1 SEM image, it can be found that the porous CuO@MnO obtained in this example 2 Compared with the precursor target produc...

Embodiment 2

[0032] Example 2: Preparation of CuO@NiO

[0033] Cu(OH) 2 Preparation of: Add 20mL 0.1M NaOH dropwise to 20mL 0.05M CuCl 2 , stirred at room temperature for 5min, washed by centrifugation, and dried at 60°C to obtain the transition metal compound precursor Cu(OH) 2 .

[0034] (1) Weigh 150mg Cu(OH) 2 , 3g NaNO 3 Mix and grind evenly with 150 mg of octadecylamine, place in a tube furnace, heat up to 350°C for calcination, and keep for 2 hours. After cooling to room temperature, take out the sample and place it in a centrifuge tube, add distilled water and wash it several times by centrifugation, remove NaNO 3 , dried at 80°C to obtain the precursor target product CuO.

[0035] (2) Weigh 50mg CuO, 50mg Ni(NO 3 ) 2 ·6H 2 O, 5g Na 2 SO 4 Mix and grind evenly, place in a tube, heat up to 300°C for calcination, and keep for 2 hours. After it cools down to room temperature, take out the sample and place it in a centrifuge tube, add distilled water and wash it several time...

Embodiment 3

[0037] Example 3: Porous NiO@Co 3 o 4 preparation of

[0038] (1) Weigh 150mgNi(NO 3 ) 2 ·6H 2 O, 3gNaNO 3 Mix and grind evenly with 150 mg of CO-630, place in a tube furnace, heat up to 500°C for calcination, and keep for 2 hours. After cooling to room temperature, take out the sample and place it in a centrifuge tube, add distilled water and wash it several times by centrifugation, remove NaNO 3 , dried at 80°C to obtain the precursor target product NiO.

[0039] (2) Weigh 50mgNiO, 50mgCo(NO 3 ) 2 ·6H 2 O, 5g LiNO 3 Mix and grind evenly, place in a tube furnace, heat up to 300°C for calcination, and keep for 2 hours. After cooling to room temperature, take out the sample and place it in a centrifuge tube, add distilled water and wash it several times to remove LiNO 3 , dried at 80°C to obtain the precursor target product NiO@Co 4 o 3 . Here the molten salt has a certain reduction or oxidation effect, and also plays a role in the formation of (Li / Na) intercalati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Charge and discharge current density | aaaaa | aaaaa |

| Capacitance | aaaaa | aaaaa |

| Capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com