Preparation method for high-strength cable

A high-strength, high-strength cable technology, which is applied in the direction of cable/conductor manufacturing, insulated cables, and conductor/cable insulation. It can solve problems that affect the physical and mechanical properties and transmission performance of cables, affect signal transmission, and break internal wires, etc., to reduce combustion. Formation and diffusion of heat, improvement of high temperature resistance, and effect of prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

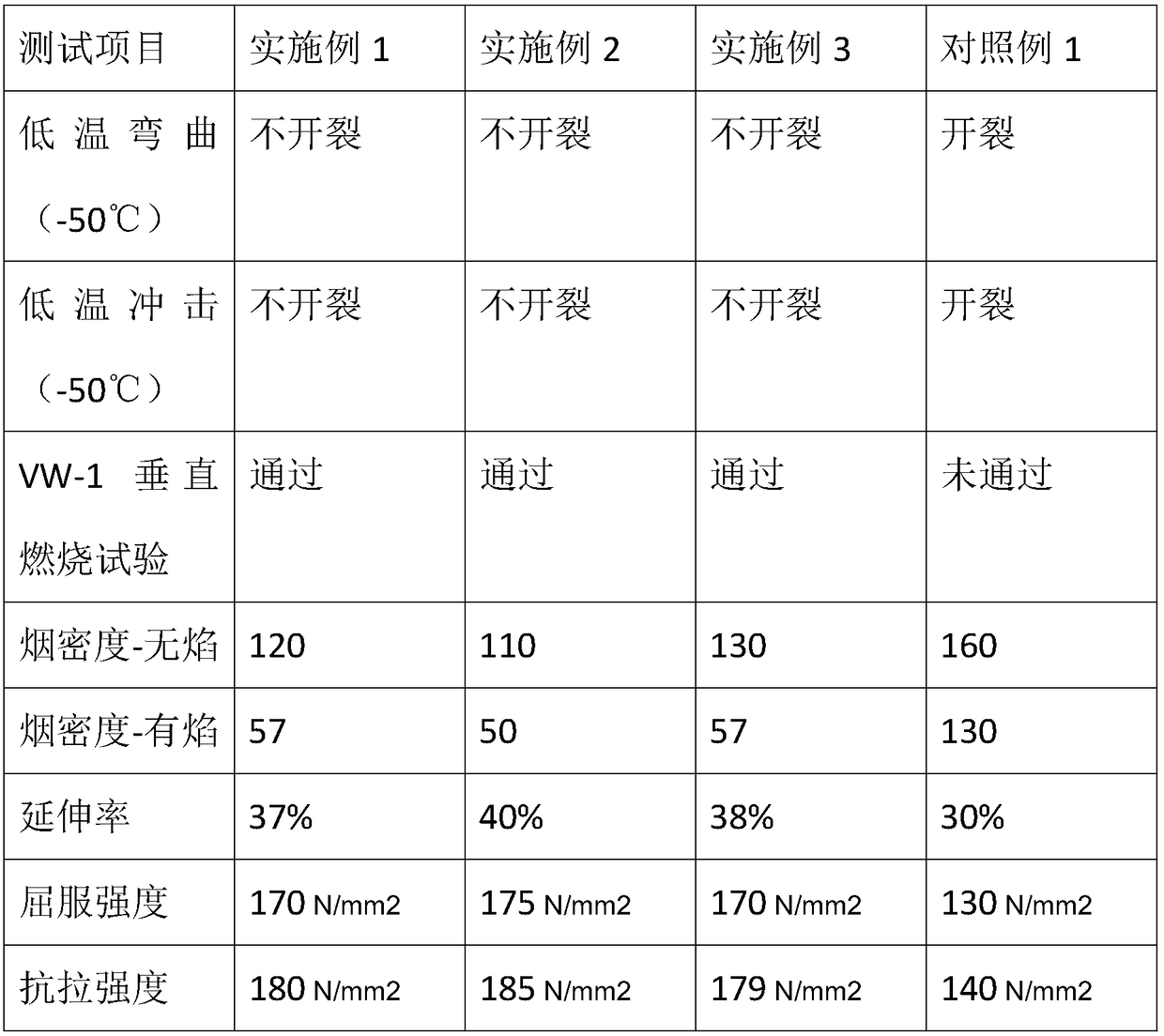

Examples

Embodiment 1

[0030] 1) The nano-semimetal bismuth bundle is used as a conductor core, the core diameter is 60nm, and the conductor core is coated with insulating high-strength cable material to form a high-strength insulating core;

[0031] The components of the cable material described in step 1) are as follows: 60 parts of modified polyurethane, 8 parts of EVA, 5 parts of acrylonitrile, 30 parts of butadiene, 1 part of antimony pentoxide, 0.5 part of vinylbisstearamide, Antioxidant CA 0.1 part, lubricant 1 part, ultraviolet absorber 0.6 part.

[0032] The modified polyurethane is modified by the following methods: 20 parts of inorganic nanosilicate, 16 parts of vegetable oil, 30 parts of trimethylolpropane, 0.01 part of catalyst, 30 parts of isocyanate, 6 parts of ethanol, 0.1 part of antioxidant, 2 parts of plasticizer 36 parts, 36 parts of phosphorus nitrogen high-strength agent, 2 parts of color paste.

[0033] 2) Step 1) 3 processed wire cores are wound around a PV lining core to ob...

Embodiment 2

[0037] 1) The nano-semimetal bismuth bundle is used as a conductor core, the core diameter is 70nm, and the conductor core is coated with insulating high-strength cable material to form a high-strength insulating core;

[0038] The components of the cable material described in step 1) are as follows: 65 parts of modified polyurethane, 9 parts of EVA, 7 parts of acrylonitrile, 40 parts of butadiene, 2 parts of antimony pentoxide, 0.7 part of vinylbisstearamide, 0.3 parts of antioxidant CA, 1.5 parts of lubricant, and 1.3 parts of ultraviolet absorber.

[0039] The modified polyurethane is modified by the following methods: 25 parts of inorganic nano-silicate, 18 parts of vegetable oil, 35 parts of trimethylolpropane, 0.02 parts of catalyst, 35 parts of isocyanate, 7 parts of ethanol, 0.05 parts of antioxidant, 3 parts of plasticizer 42 parts, 42 parts of phosphorus nitrogen high strength agent, 3 parts of color paste.

[0040] 2) Step 1) 4 processed wire cores are wound around...

Embodiment 3

[0044] 1) The nano-semimetal bismuth bundle is used as a conductor core, the core diameter is 80nm, and the conductor core is coated with insulating high-strength cable material to form a high-strength insulating core;

[0045] The components of the cable material described in step 1) are as follows: 70 parts of modified polyurethane, 10 parts of EVA, 10 parts of acrylonitrile, 50 parts of butadiene, 3 parts of antimony pentoxide, 1 part of vinylbisstearamide, Antioxidant CA 0.5 parts, lubricant 2 parts, ultraviolet absorber 2 parts.

[0046] Modified polyurethane is modified by the following methods: 30 parts of inorganic nano-silicate, 20 parts of vegetable oil, 40 parts of trimethylolpropane, 0.03 parts of catalyst, 40 parts of isocyanate, 8 parts of ethanol, 1 part of antioxidant, 4 parts of plasticizer 46 parts, 46 parts of phosphorus nitrogen high-strength agent, 4 parts of color paste.

[0047] 2) Step 1) 5 processed cores are wound around a PV filling core to obtain a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com