Multi-scale multi-phase dispersion strengthening iron-based alloy and preparing and representation method thereof

A technology for dispersion strengthening, iron-based alloys, applied in the field of powder metallurgy materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

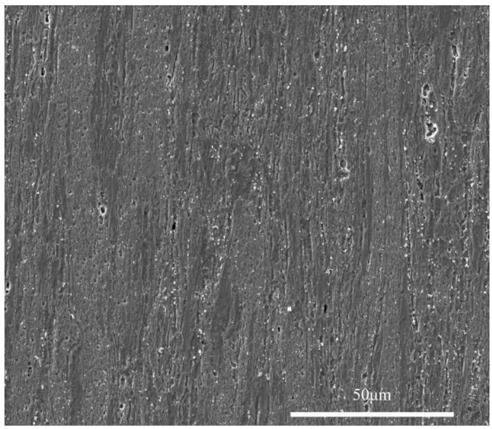

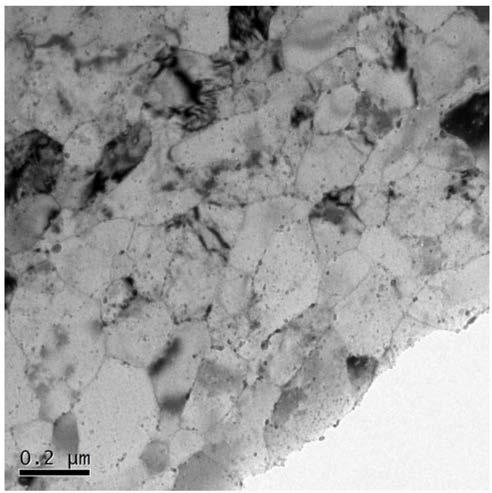

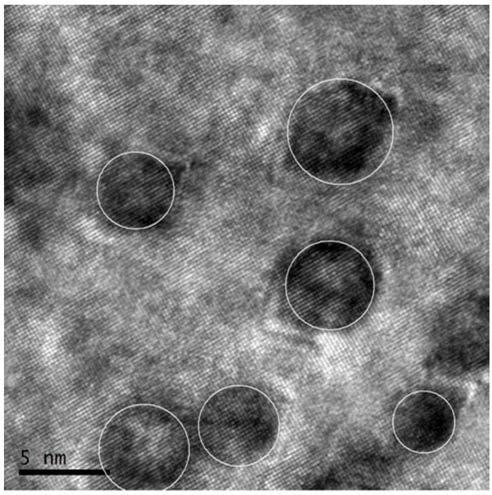

[0094] Embodiment 1: Fe-14Cr-3W-0.4Ti-1.5Y 2 o 3 (wt.%) Alloy

[0095] Powder preparation:

[0096] First, weigh the gas-atomized Fe-14Cr-3W-0.4Ti (wt.%) iron-based pre-alloyed powder and Y 2 o 3A total of 150g of powder was put into a ball mill jar. Among them, the iron-based pre-alloyed powder particle size is less than or equal to 150μm, Y 2 o 3 Powder particle size is less than or equal to 45μm. According to the ball-to-material ratio of 10:1, the diameter of the grinding balls is 20mm:15mm:10mm:8mm:5mm:3mm=1:1:1:1:1:1, weigh 1500g of grinding balls and put them into the ball milling tank.

[0097] Step 2: Seal the ball mill tank, vacuumize it, the vacuum degree is less than or equal to 0.1Pa, and fill it with high-purity argon.

[0098] Step 3: Put the ball mill jar into the vertical planetary ball mill for mechanical ball milling; set the parameters of the mechanical ball mill, the rotation speed is 300r / min, and the mechanical ball milling time is 60h. During b...

Embodiment 2

[0115] Embodiment 2: Fe-14Cr-3W-0.4Ti-1.0Y 2 o 3 (wt.%) Alloy

[0116] Powder preparation:

[0117] First, according to the mass ratio of 99:1, weigh the gas-atomized Fe-14Cr-3W-0.4Ti (wt.%) iron-based pre-alloyed powder and Y 2 o 3 A total of 150g of powder was put into a ball mill jar. Among them, the iron-based pre-alloyed powder particle size is less than or equal to 150μm, Y 2 o 3 Powder particle size is less than or equal to 75μm. According to the ball-to-material ratio of 10:1, the diameter of the grinding balls is 20mm:15mm:10mm:8mm:5mm:3mm=1:1:1:1:1:1, weigh 1500g of grinding balls and put them into the ball milling tank.

[0118] Step 2: Seal the ball mill tank, vacuumize it, the vacuum degree is less than or equal to 0.1Pa, and fill it with high-purity argon.

[0119] Step 3: Put the ball mill jar into the vertical planetary ball mill for mechanical ball milling; set the parameters of the mechanical ball mill, the rotation speed is 320r / min, and the mechanic...

Embodiment 3

[0127] Embodiment 3: Fe-14Cr-3W-0.4Ti-2.0Y 2 o 3 (wt.%) Alloy

[0128] Powder preparation:

[0129] First, weigh the gas-atomized Fe-14Cr-3W-0.4Ti (wt.%) iron-based pre-alloyed powder and Y 2 o 3 A total of 150g of powder was put into a ball mill jar. Among them, the iron-based pre-alloyed powder particle size is less than or equal to 150μm, Y 2 o 3 Powder particle size is less than or equal to 45μm. According to the ball-to-material ratio of 10:1, the diameter of the grinding balls is 20mm:15mm:10mm:8mm:5mm:3mm=1:1:1:1:1:1, weigh 1500g of grinding balls and put them into the ball milling tank.

[0130] Step 2: Seal the ball mill tank, vacuumize it, the vacuum degree is less than or equal to 0.1Pa, and fill it with high-purity argon.

[0131] Step 3: Put the ball mill jar into the vertical planetary ball mill for mechanical ball milling; set the parameters of the mechanical ball mill, the rotation speed is 300r / min, and the mechanical ball milling time is 60h. During ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com