Ceramic sponge material method for preparing nanowire woven microspheres by reverse template method

A technology of ceramic sponge and nanowire, which is applied in the field of ceramic materials and achieves the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A kind of reverse template method prepares the ceramic sponge material method of nanowire weaving microsphere, comprises the steps:

[0018] (1) Add water-soluble carbon black with 40 wt% mass of silica sol particles to 20 wt% alkaline silica sol (average particle size: 20nm), and mix for 12 hours with a planetary ball mill.

[0019] (2) Add 0.1 wt.% dodecyltrimethylammonium bromide to the above slurry, and adjust the pH to 11.5.

[0020] (3) Foaming the slurry at a rotational speed of 1500-2000 rpm for 20 minutes by mechanical stirring to obtain a stable foam slurry of silica sol and carbon black particles.

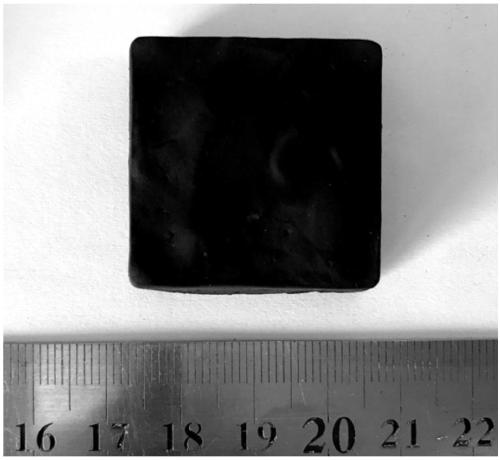

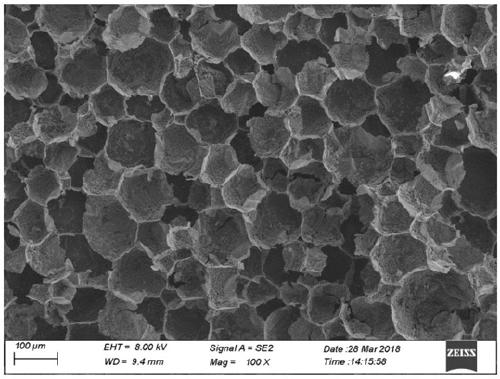

[0021] (4) keep the humidity in a constant temperature and humidity box as 70%, and the temperature is 20°C to dry the particle-stabilized foam to obtain a porous green body, such as figure 1 shown. Its microstructure is as figure 2 shown.

[0022] (5) The foam body obtained above was reacted and sintered in an atmospheric nitrogen environment, heated to 1650...

Embodiment 2

[0024] A kind of reverse template method prepares the ceramic sponge material method of nanowire weaving microsphere, comprises the steps:

[0025] (1) Add water-soluble carbon black with a mass of 70 wt% of silica sol particles to 5 wt% alkaline silica sol (average particle size: 50 nm), and mix for 12 hours using a planetary ball mill.

[0026] (2) Add 0.5wt% cetyltrimethylammonium chloride to the above slurry to adjust the pH to 9.0.

[0027] (3) Foaming the slurry at a rotational speed of 1500-2000 rpm for 5 minutes by mechanical stirring to obtain a stable foam slurry of silica sol and carbon black particles.

[0028] (4) Dry the foam in a constant temperature and humidity box in an environment of 95% humidity and 35° C. to obtain a dry billet.

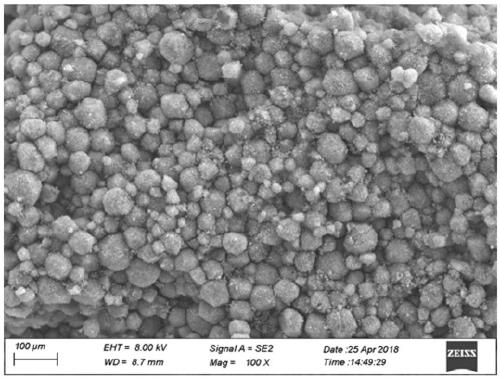

[0029] (5) Sinter the foam body obtained above under an argon atmosphere at normal pressure, heat it to 1450°C at a heating rate of 0.5°C / min, and then keep it warm for 5h. The prepared SiC nanowire braided microspheres are as f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com