High-alloy and corrosion-resistant continuous oil pipe formed by high frequency induction welding and manufacturing method thereof

A high-frequency induction welding and corrosion-resistant technology, which is applied in high-frequency current welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of high technical difficulty and undiscovered high-frequency induction welding of high-alloy duplex stainless steel, and achieve Good fatigue life, good resistance to uniform corrosion, and high welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

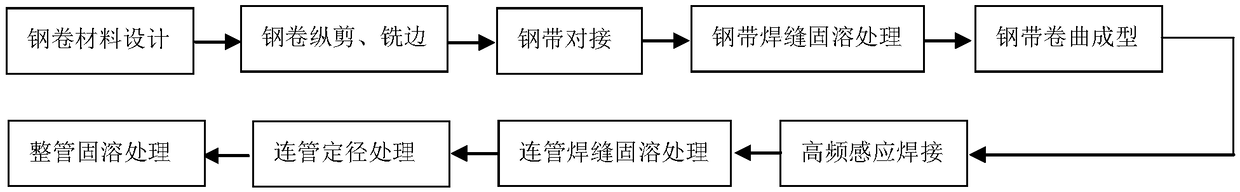

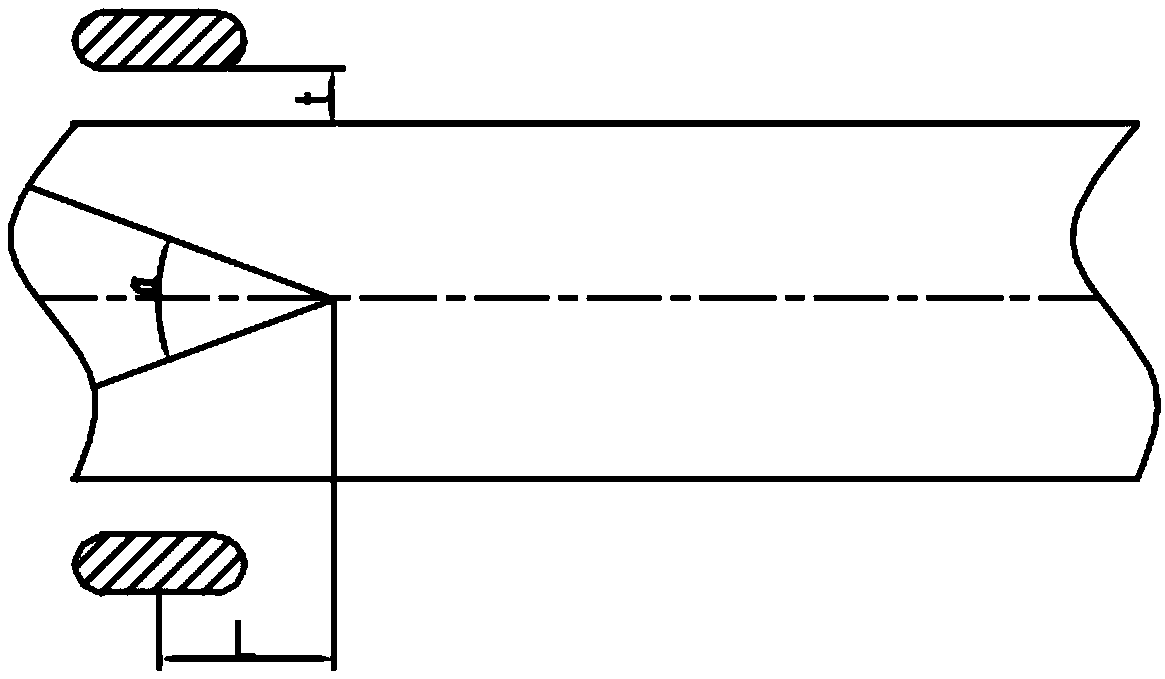

[0034] A high-frequency induction welded high-alloy corrosion-resistant coiled tubing, the coiled tubing is a duplex stainless steel coiled tubing, the duplex stainless steel coiled tubing is a ferrite and austenitic duplex stainless steel, and the alloy elements of the duplex stainless steel coiled tubing are determined according to the quality In terms of fractions, it includes the following composition and components: C 0.012%, Mn 1.1%, P 0.013%, S 0.002%, Si 0.55%, Cr 22.5%, Mo 3.2%, Ni 4.8%, N 0.17%, Fe balance. It is smelted by EAF AC electric arc furnace, and then refined by VOD vacuum electric arc furnace. Through chemical composition ratio and hot rolling + solid solution treatment, a ferrite + austenite two-phase structure is obtained, wherein the ferrite content is 35%. After the pickling treatment, the finished steel coil material with a wall thickness of 0.175in was obtained. The steel coil is longitudinally cut according to the outer diameter requirement of the ...

Embodiment 2

[0038] A high-frequency induction welded high-alloy corrosion-resistant coiled tubing, the coiled tubing is a duplex stainless steel coiled tubing, the duplex stainless steel coiled tubing is a ferrite and austenitic duplex stainless steel, and the alloy elements of the duplex stainless steel coiled tubing are determined according to the quality In terms of fractions, it includes the following composition and components: C 0.01%, Mn 1.25%, P 0.017%, S 0.002%, Si 0.36%, Cr 25%, Mo 4.5%, Ni 8.0%, N 0.26%, Fe balance. It is smelted by EAF AC electric arc furnace, and then refined by AOD argon oxygen decarburization. Through chemical component distribution and hot rolling + solution treatment, a ferrite + austenite two-phase structure is obtained, wherein the ferrite content is 55%. After the pickling treatment, the finished steel coil material with a wall thickness of 0.156in was obtained. The steel coil is longitudinally cut according to the outer diameter requirement of 1.75in...

Embodiment 3

[0042] A high-frequency induction welded high-alloy corrosion-resistant coiled tubing, the coiled tubing is a duplex stainless steel coiled tubing, the duplex stainless steel coiled tubing is a ferrite and austenitic duplex stainless steel, and the alloy elements of the duplex stainless steel coiled tubing are determined according to the quality Fractional, including the following composition and components: C 0.018%, Mn 0.96%, P 0.01%, S 0.002%, Si 0.45%, Cr 30.0%, Mo 1.5%, Ni 4.5%, N 0.4%, Fe balance . It is smelted by EAF AC electric arc furnace, and then refined by VOD vacuum electric arc furnace. Through chemical composition ratio and hot rolling + solution treatment, a ferrite + austenite two-phase structure is obtained, wherein the ferrite content is 45%. After the pickling treatment, the finished steel coil material with a wall thickness of 0.156in was obtained. The steel coil is longitudinally cut according to the outer diameter requirement of the 2in pipe. After mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com