Method for improving organic matter adsorption performance of activated carbon, prepared product and use thereof

A technology of activated carbon adsorption and organic matter, applied in separation methods, chemical instruments and methods, inorganic chemistry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

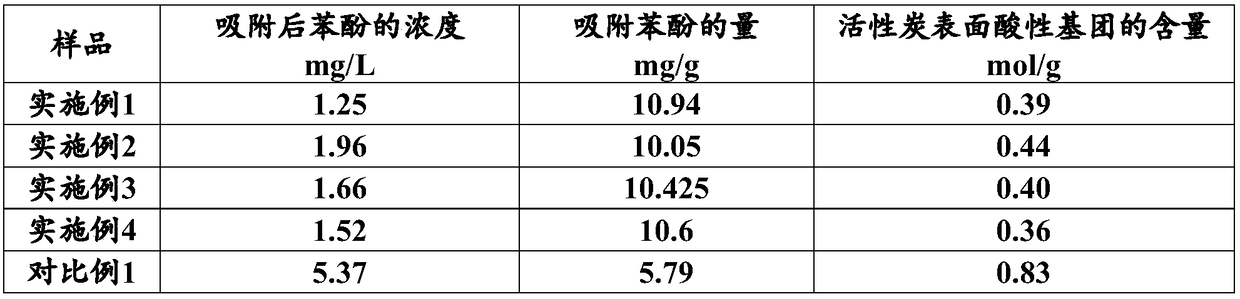

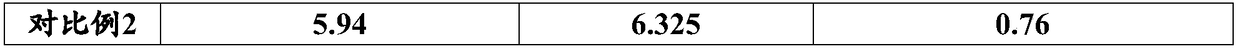

Examples

preparation example Construction

[0070] The preparation method of the present invention will be further described in detail in conjunction with specific examples below. It should be understood that the following examples are only for illustrating and explaining the present invention, and should not be construed as limiting the protection scope of the present invention. All technologies realized based on the above contents of the present invention are covered within the scope of protection intended by the present invention.

[0071] The experimental methods used in the following examples are conventional methods unless otherwise specified; the reagents and materials used in the following examples can be obtained from commercial sources unless otherwise specified.

Embodiment 1

[0073] 1.1 Preparation of spherical polymer

[0074] Under argon protection, add 0.011mol 2,2 bis(trifluoromethyl)diaminobenzidine to 14.94g polar solvent N,N-dimethylacetamide in a 250mL three-necked flask equipped with mechanical stirring , after stirring to completely dissolve the diamine, add 0.01mol 3,3',4,4'-diphenyl ether tetracarboxylic dianhydride to the reaction system, react for 4 hours, add 0.0005mol norbornene anhydride, and continue the reaction for 24 hours to obtain Polyamic acid soluble.

[0075] The mixture of 2.26g triethylamine and 0.22g pyridine is used as a catalyst, the catalyst is added to the polyamic acid solution, and 9.24g dehydrating agent acetic anhydride is added, and the reaction is continued for 24 hours to obtain a polyimide prepolymer solution, and then the polyimide After diluting the imide prepolymer solution with the polar solvent N-methylpyrrolidone to an equal volume, drop it into methanol to obtain a precipitate, wash and filter the pr...

Embodiment 2

[0086]2.1 step is the same as 1.1 in embodiment 1

[0087] 2.2 Carbonization

[0088] Put the spherical polymer in step 2.1 into an acid-resistant and alkali-resistant rotary tube furnace, and carry out the following carbonization treatment at a heating rate of 2°C / min under a nitrogen atmosphere and an ammonia atmosphere (flow ratio: 4:1):

[0089] Heat to 110°C and stay for 100 minutes;

[0090] Heat to 500°C and stay for 400 minutes;

[0091] Continue to heat up at a heating rate of 3°C / min, and carry out carbonization treatment in a mixed atmosphere with a volume percentage of 3% of oxygen. At this time, because ammonia gas is generated during the carbonization process of the spherical polymer, the amount of ammonia gas introduced is reduced to The flow ratio is 8:1:

[0092] Heat to 650°C and hold for 600 minutes. Lower the temperature to obtain carbonized products.

[0093] 2.3 Activation

[0094] In a rotary tube furnace, under a mixed atmosphere of water vapor, n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

| Median aperture | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com