Gel product instant-dissolving block and preparation method thereof

A product, instant technology, applied in pharmaceutical formulations, medical preparations with non-active ingredients, and medical preparations containing active ingredients, etc., can solve the problems of insoluble block glue products, etc., achieve special texture, meet packaging and Transportation needs, the effect of solid appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

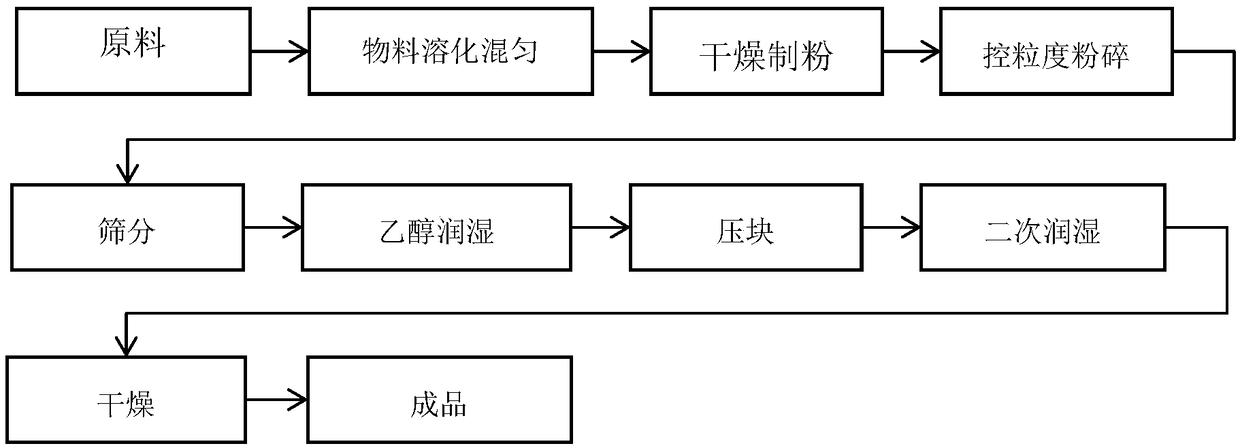

[0031] In order to overcome the technical problems of poor solubility, inconvenient use, and a single way of taking the same product in traditional block-shaped gelatinous products, the present invention provides a preparation method for instant blocks of gelatinous products, which includes the following steps:

[0032] (1) The raw material glue is dissolved in water, and the glue is obtained after concentration;

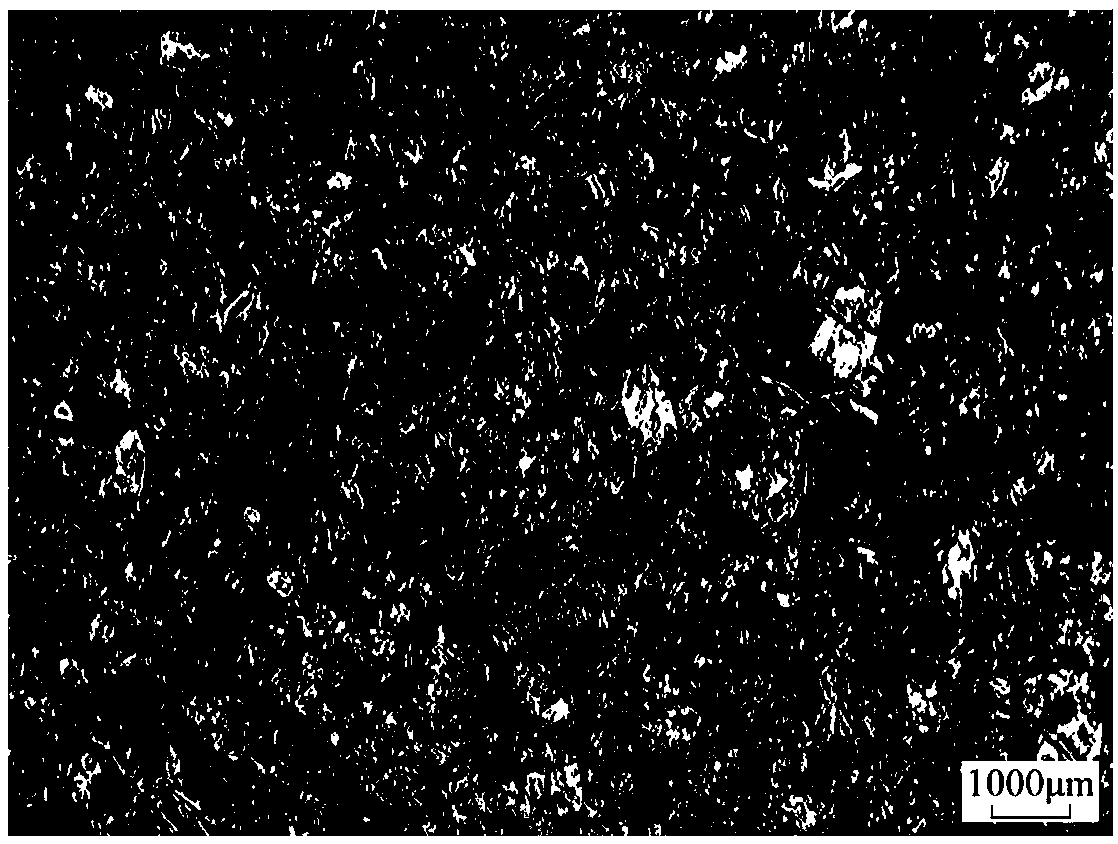

[0033] (2) the glue solution is processed through vacuum belt drying to obtain a honeycomb-shaped colloid;

[0034] (3) pulverize the colloid, and sieve to obtain flake rubber powder with a particle size not less than 80 mesh;

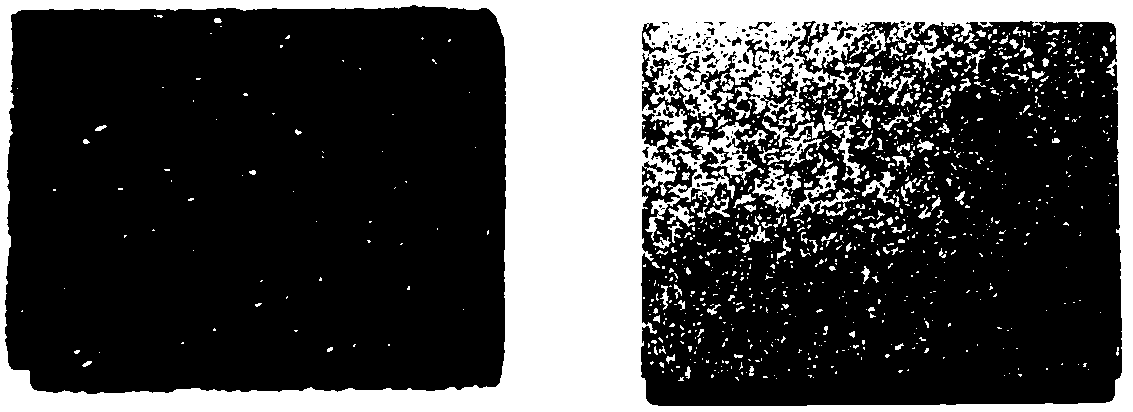

[0035] (4) After the rubber powder is wetted with 85-95% alcohol, it is pressed with a compression ratio of 30%-60%, and the obtained pressed block is the instant block of the rubber product.

[0036] In the present invention, the raw material glue is the well-known medicinal and edible homologous glue or glue-like traditional Chinese medic...

Embodiment 1

[0051] (1) Add the donkey-hide gelatin raw material together with a certain amount of rock sugar and yellow rice wine into water of 5 times the total mass, heat and stir to dissolve completely. Concentrate the melted donkey-hide gelatin solution to a relative density of 1.16-1.19 (75°C);

[0052] (2) The concentrated donkey-hide gelatin liquid is dried by a vacuum belt drying process to obtain a coarse powder. The vacuum belt drying parameters are: feed temperature 67°C, feed speed 19L / h, crawler running speed 15cm / min; heating temperature of the first, second, third, fourth and fifth sections are 95±5°C respectively , 97±5℃, 97±5℃, 97±5℃, 25±5℃; cutter 25 seconds / time, vacuum degree 98KPa.

[0053] (3) Grinding with particle size control: the coarse powder obtained by drying is pulverized by a low-speed pulverizer at a frequency of 15 Hz using a sieve with an aperture of 2 to 3 mm. Then pass through a 30-mesh to 80-mesh vibrating sieve and sieve, and take the particles betw...

Embodiment 2

[0060] (1) Add the tortoise shell gum raw material and rock sugar to 3 times the amount of water, heat and stir to dissolve completely. Concentrate the melted glue to a relative density of 1.16-1.19 (75°C);

[0061] (2) The concentrated tortoise shell glue solution is dried by a vacuum belt drying process to obtain a coarse powder. Vacuum belt drying parameters are: feed temperature 62°C, feed speed 14L / h, crawler running speed 13cm / min; heating temperature of the first, second, third, fourth and fifth sections are respectively 95±5°C , 97±5℃, 97±5℃, 97±5℃, 25±5℃; cutter 19 seconds / time, vacuum degree 98KPa.

[0062] (3) Grinding with particle size control: use a low-speed pulverizer to pulverize the dried coarse powder with a 2-3mm aperture screen at a frequency of 13Hz, and then sieve through a 30-mesh-80-mesh vibrating sieve, and take a 30-mesh-80-mesh sieve The particles in between are tortoise shell glue powder, set aside.

[0063] (4) Spray evenly the alcohol with a v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com