Aluminum nitride ceramic pipe shell and fabrication method thereof

A technology of aluminum nitride ceramics and a production method, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve problems such as large signal transmission loss, signal delay, and large square resistance, and achieve good heat dissipation and light reduction. Small size and weight, low density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions of the present invention will be further clearly and completely described below in conjunction with the accompanying drawings and specific embodiments.

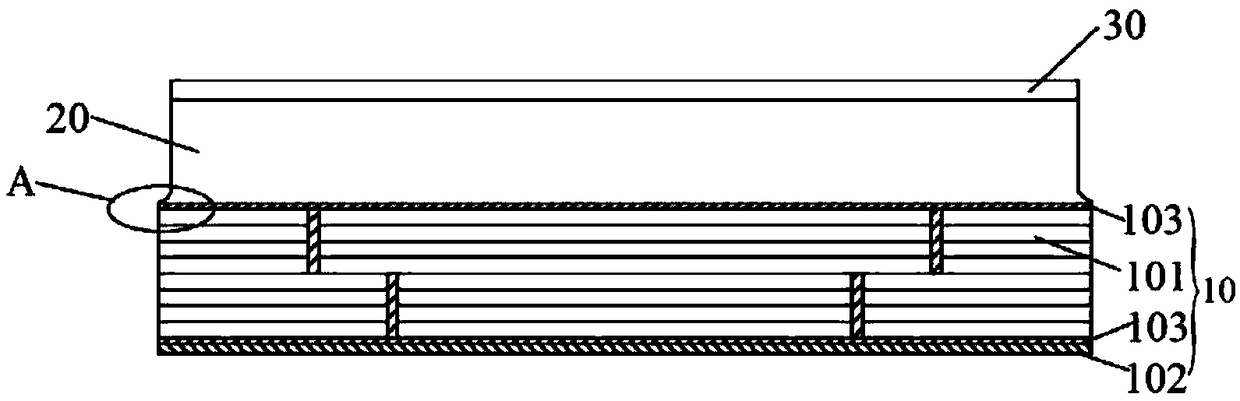

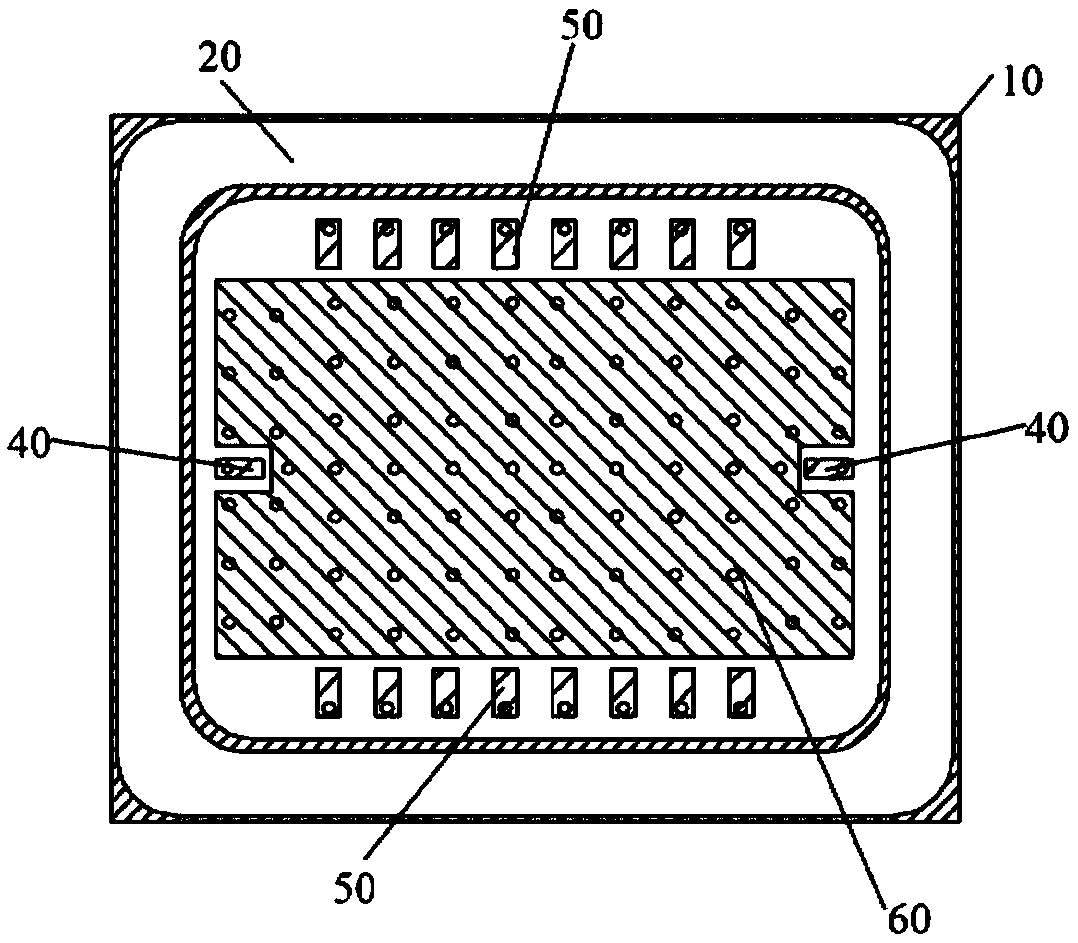

[0035] Such as figure 1 As shown, an aluminum nitride ceramic shell is composed of a base plate 10, a metal ring frame 20 and a cover plate 30. The base plate 10 is composed of an aluminum nitride ceramic substrate 101 and a bottom pad 102 located at the lower part of the aluminum nitride ceramic substrate 101. , wherein the surface of the aluminum nitride ceramic substrate 101 is covered with a metal film layer 103, and the material of the metal ring frame 20 can be Kovar or titanium alloy. In the embodiment of the present application, the metal ring frame 20 is a Kovar ring frame.

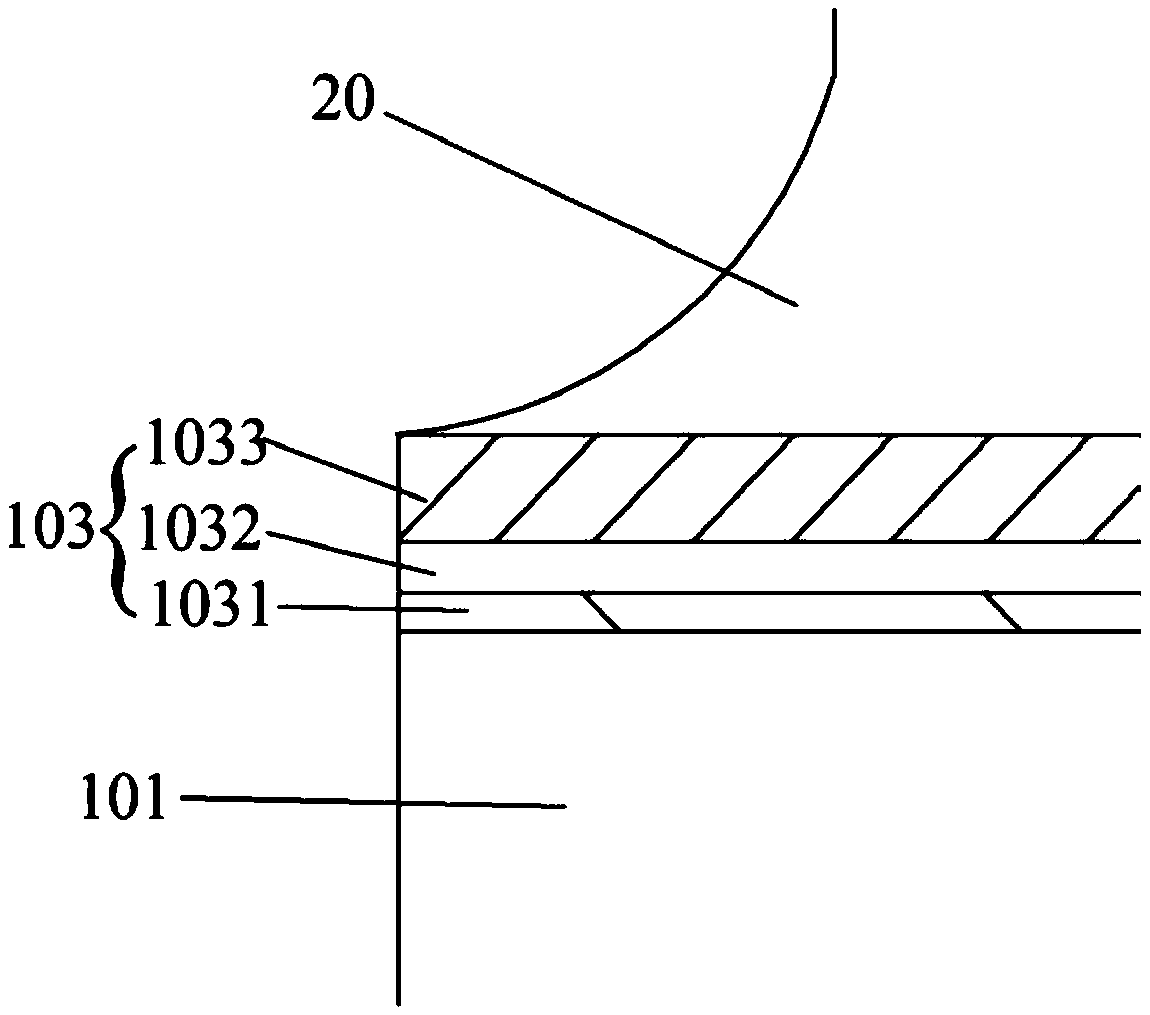

[0036] Further, by figure 1 As shown, the upper and lower surfaces of the aluminum nitride ceramic substrate 101 are covered with a metal thin film layer 103, please refer to figure 2, the metal thin film layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com