Laser surface alloying method

A laser alloying and laser technology, which is applied in the field of laser surface alloying, can solve the problems of long-term heat accumulation, high stress of the workpiece, and increased difficulty, and achieve the effects of small deformation, increased wear resistance, and improved wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

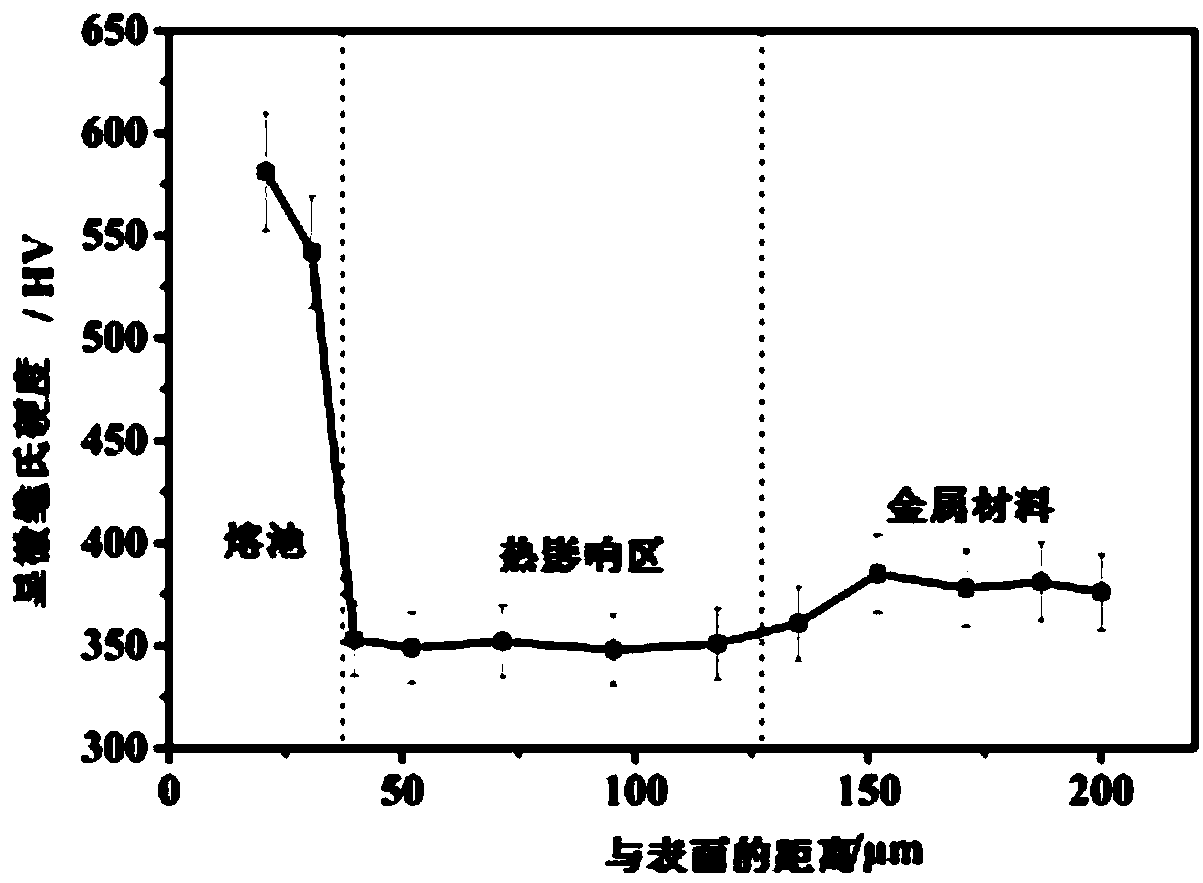

[0030] Embodiment 1 laser surface alloying method X1

[0031] Specifically include the following steps:

[0032] The carbon coating process consists of colloid preparation containing carbon powder, carbon coating on the surface of the workpiece, and drying. The colloid preparation adopts the method of compound addition, that is, adding alcohol and acetone to the nano-sized carbon powder to obtain a colloid with a high viscosity, and then adding carbon powder, alcohol and acetone in sequence after standing for 5 minutes to further improve its fluidity. Dispersion. After the preparation of the colloid is completed, the self-designed carbon coating device is used to coat the surface of the cleaned and dried workpiece, and the quantitative control of the carbon powder is carried out by adjusting the brush in the vertical direction. Drying is then carried out to obtain a workpiece coated with uniform carbon powder on the surface.

[0033] In the process of laser alloying, it is ...

Embodiment 2

[0039] Embodiment 2 laser surface alloying method X2

[0040]Add alcohol and acetone to the nano-sized carbon powder to obtain a colloid with high viscosity. After standing for 5 minutes, add carbon powder, alcohol and acetone in order to further improve its fluidity and dispersion. After the preparation of the colloid is completed, the self-designed carbon coating device is used to coat the surface of the cleaned and dried workpiece, and the quantitative control of the carbon powder is carried out by adjusting the brush in the vertical direction. Drying is then carried out to obtain a workpiece coated with uniform carbon powder on the surface.

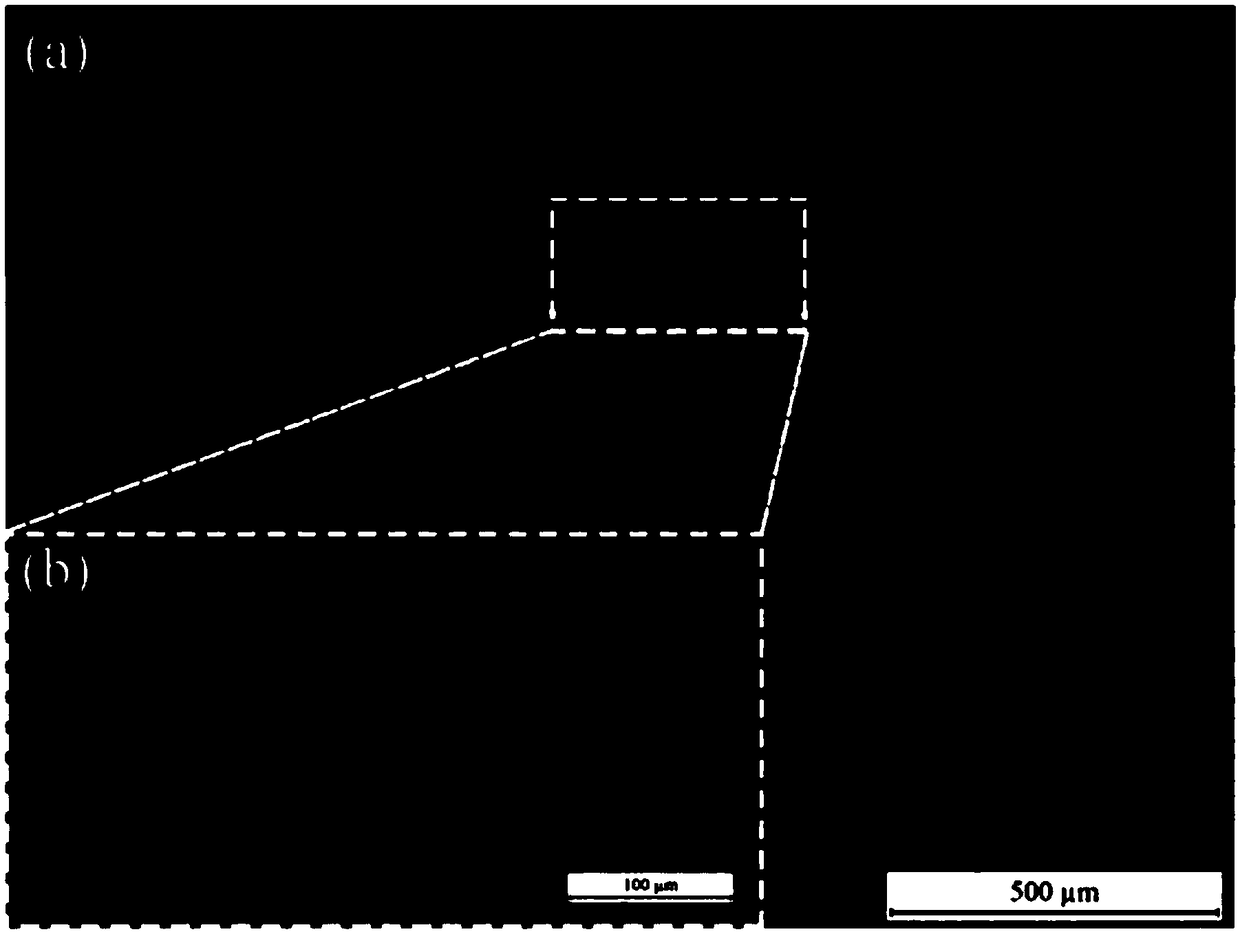

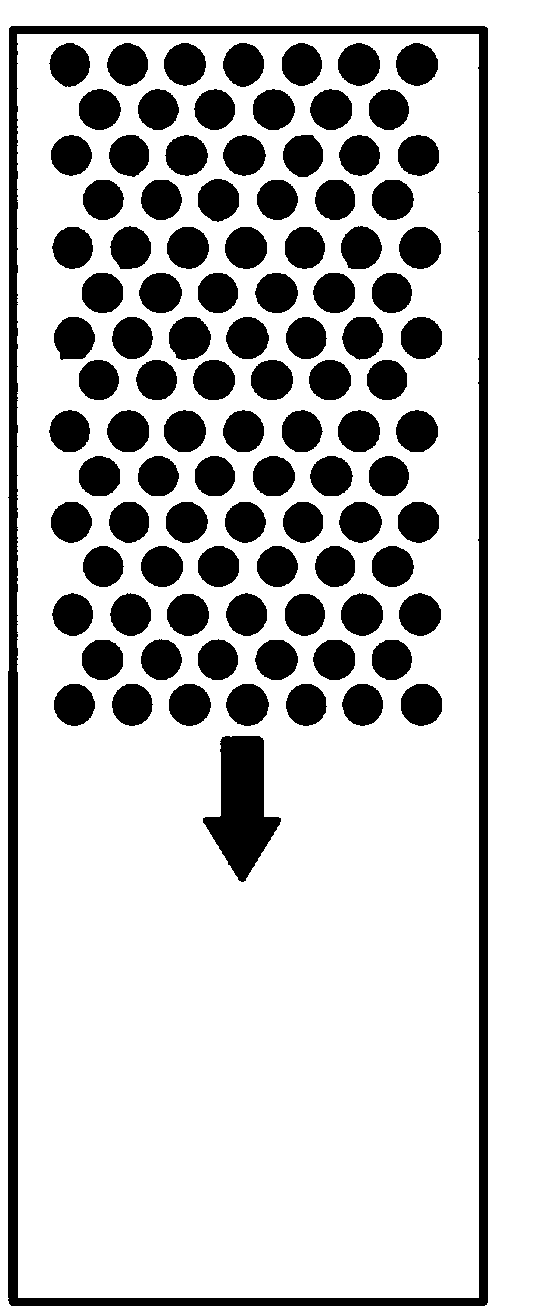

[0041] Divide the surface of the metal workpiece into 5 work areas, each work area is 5×5cm in size, and each work area is divided into 100 light spots, each light spot size is 4.5×4.5mm. A white border with a width of about 0.5mm flows out from the edge of the workpiece.

[0042] Put the workpiece into the operation box, use argon ...

Embodiment 3

[0047] Embodiment 3 laser surface alloying method X3

[0048] Add alcohol and acetone to the nano-sized carbon powder to obtain a colloid with high viscosity. After standing for 5 minutes, add carbon powder, alcohol and acetone in order to further improve its fluidity and dispersion. After the preparation of the colloid is completed, the self-designed carbon coating device is used to coat the surface of the cleaned and dried workpiece, and the quantitative control of the carbon powder is carried out by adjusting the brush in the vertical direction. Drying is then carried out to obtain a workpiece coated with uniform carbon powder on the surface.

[0049] Divide the surface of the metal workpiece into 2 working areas, the size of each working area is 3×3cm, divide each working area into 100 light spot positions, and the size of each light spot position is 2.5×2.5mm. A white border with a width of about 0.5mm flows out from the edge of the workpiece.

[0050] Put the workpiece...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| oxygen content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com