Energy-saving and environmentally-friendly thermal insulation material and preparation method thereof

A thermal insulation material, energy-saving and environmental protection technology, applied in the field of thermal insulation materials, can solve the problems of thermal insulation material performance degradation, low work efficiency of installers, failure to achieve energy conservation and environmental protection, etc., to achieve improved thermal insulation effect, which is conducive to popularization and application, The effect of preventing the conduction of heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

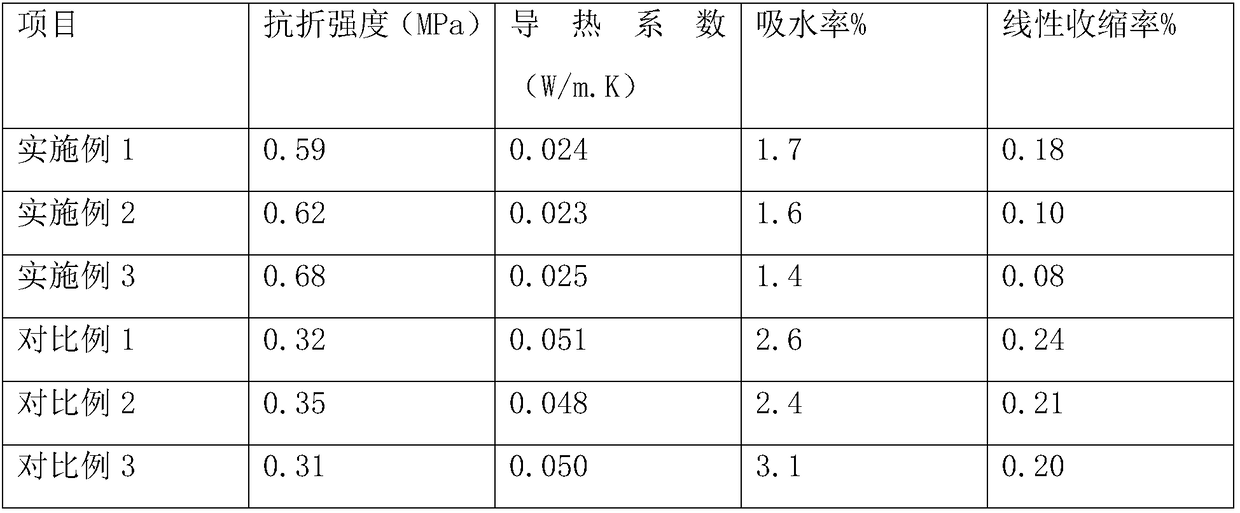

Examples

Embodiment 1

[0032] An energy-saving and environment-friendly thermal insulation material, comprising the following raw materials in parts by weight: 20 parts of calcium silicate plate waste powder, 4 parts of nano-scale superfine calcium carbonate, 20 parts of modified shell powder, 10 parts of sodium-based white bentonite, organic silicon 4 parts of water-repellent agent, 2 parts of cold water type polyvinyl alcohol, 2 parts of powdered silicone defoamer, 30 parts of high alumina refractory fiber, 10 parts of polyethylene oxide block polybutylacrylate, 5 parts of water glass, 30 parts of water.

[0033] Nanoscale ultrafine calcium carbonate is calcium carbonate micropowder with particles in the range of 50-150nm.

[0034] The preparation method of modified shell powder comprises the following steps:

[0035] (1), shells are washed with deionized water, dried after removing the cuticle, naturally cooled to room temperature to obtain dried shells, and the dried shells are soaked in a 5% s...

Embodiment 2

[0047]An energy-saving and environment-friendly thermal insulation material, comprising the following raw materials in parts by weight: 25 parts of calcium silicate plate waste powder, 7 parts of nano-scale superfine calcium carbonate, 30 parts of modified shell powder, 15 parts of sodium-based white bentonite, organic silicon 6 parts of water-repellent agent, 4 parts of cold-water polyvinyl alcohol, 3 parts of powdered silicone defoamer, 35 parts of high-alumina refractory fiber, 12.5 parts of polyethylene oxide block polybutylacrylate, 10 parts of water glass, 35 parts of water.

[0048] Nanoscale ultrafine calcium carbonate is calcium carbonate micropowder with particles in the range of 50-150nm.

[0049] The preparation method of modified shell powder comprises the following steps:

[0050] (1), the shells are washed with deionized water, dried after removing the surface cuticle, naturally cooled to room temperature to obtain dried shells, and the dried shells are soaked ...

Embodiment 3

[0062] An energy-saving and environment-friendly thermal insulation material, comprising the following raw materials in parts by weight: 30 parts of calcium silicate plate waste powder, 10 parts of nano-scale superfine calcium carbonate, 40 parts of modified shell powder, 20 parts of sodium-based white bentonite, organic silicon 8 parts of water-repellent agent, 6 parts of cold water polyvinyl alcohol, 4 parts of powdered silicone defoamer, 40 parts of high-alumina refractory fiber, 15 parts of polyethylene oxide block polybutylacrylate, 15 parts of water glass, 40 parts of water.

[0063] Nanoscale ultrafine calcium carbonate is calcium carbonate micropowder with particles within the range of 150nm.

[0064] The preparation method of modified shell powder comprises the following steps:

[0065] (1), the shells are washed with deionized water, dried after removing the surface cuticle, naturally cooled to room temperature to obtain dried shells, and the dried shells are soaked...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com