Method for preparing flat ceramic membranes by means of compression molding and product prepared by aid of method

A press molding and ceramic membrane technology, which is applied in the field of flat ceramic membrane preparation, can solve the problems of complex process and easy deformation of membrane parts, and achieve the effects of easy control of operating conditions, small deformation of membrane parts and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

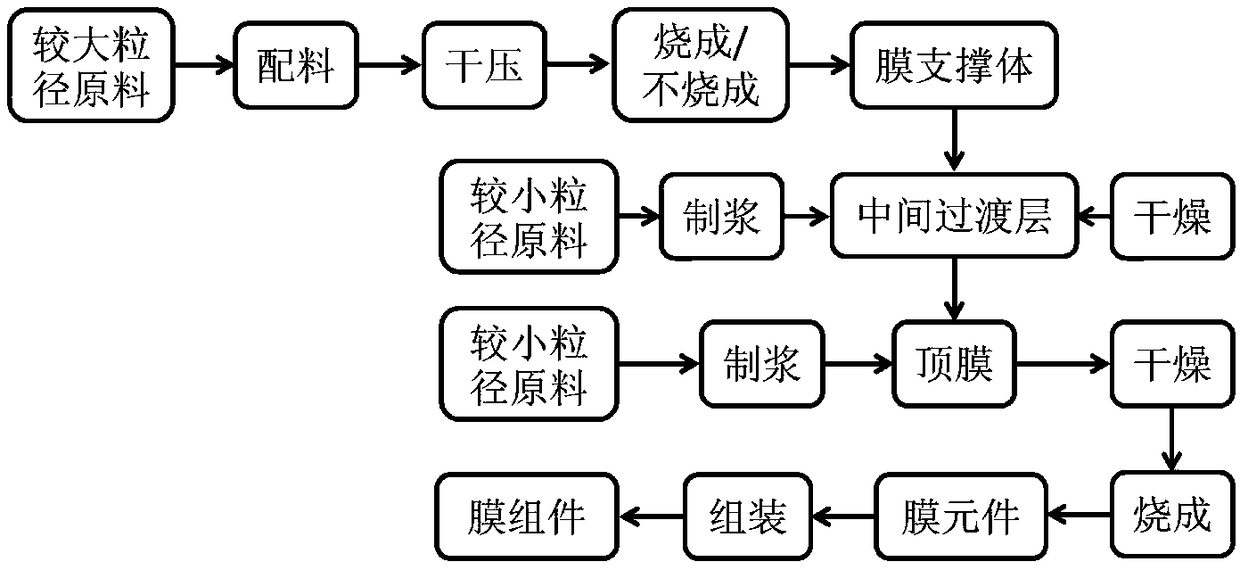

[0027] A kind of preparation method of flat ceramic film compression molding of present embodiment, such as figure 1 As shown, the steps are as follows:

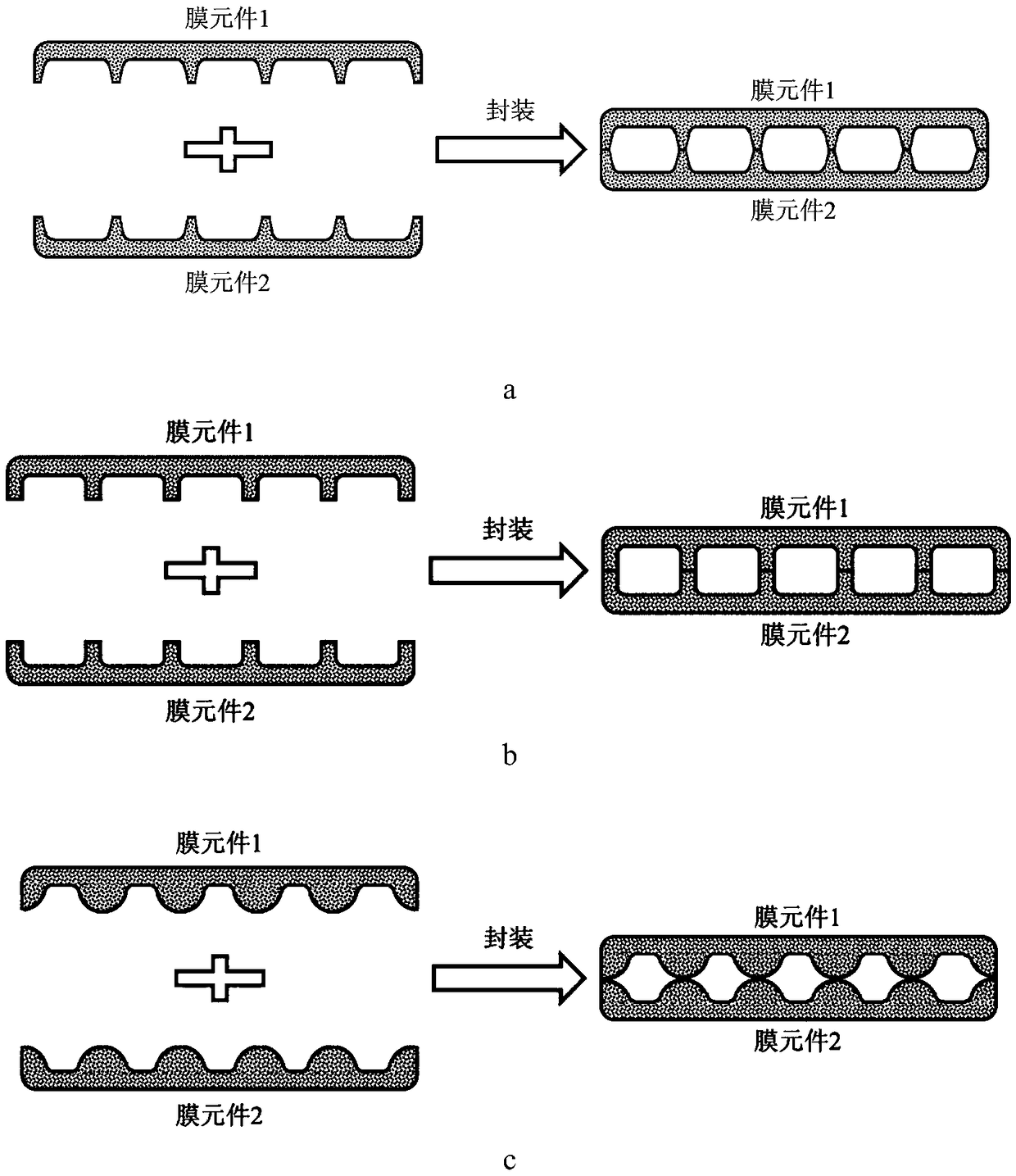

[0028] (1) Use alumina powder with an average particle size of 50 μm as raw material, add water in an amount of 8wt% of the alumina powder, and 0.5wt% polyvinyl alcohol solution (concentration is 5wt%), after mixing, stale 1. After granulation, under a pressure of 50 MPa, a flat ceramic membrane support body with a size of 300 x 100 x 1 mm in length and an arc-shaped outer edge (arc is π / 3) is pressed out, and the lower surface There are 39 convex strips with a height of 0.5 mm that are consistent with the length direction of the support and arranged side by side at intervals (the cross-section of the convex strips is as follows: figure 2 The one shown in a is an inverted trapezoid with a hypotenuse angle of 30°, a width of the bottom of 0.5mm, and a chamfering radian of the joint between the convex strip and the support b...

Embodiment 2

[0034] A kind of preparation method of flat ceramic film compression molding of present embodiment, such as figure 1 As shown, the steps are as follows:

[0035] (1) With the cordierite powder having an average particle diameter of 5 μm as a raw material, the amount of the cordierite powder added is 6wt% water, 5wt% starch, and 0.5wt% carboxymethyl cellulose solution (concentration is 10wt%) ), after mixing, aging, and granulation, under a pressure of 40MPa, press out a flat ceramic membrane support with a size of 600 x 200 x 1mm and an arc-shaped outer edge (radian 2π / 3) Green body, its lower surface is evenly distributed with 49 convex strips with a height of 1mm that are consistent with the length direction of the support and arranged side by side at intervals (the cross section of the convex strips is as follows: figure 2 The one shown in a is an inverted trapezoid, the trapezoid hypotenuse angle is 60°, the width of the bottom is 1mm, and the chamfering arc of the joint...

Embodiment 3

[0040] A kind of preparation method of flat ceramic film compression molding of present embodiment, such as figure 1 As shown, the steps are as follows:

[0041] (1) Using silicon carbide powder with an average particle size of 5 μm as a raw material, add water in an amount of 3wt% of the silicon carbide powder, 5wt% carbon powder, and 1wt% polyvinyl alcohol solution (concentration is 10wt%), After mixing, aging, and granulation, under a pressure of 20 MPa, a flat ceramic membrane support body with a size of 600 x 100 x 2mm and an arc-shaped outer edge (radian π / 3) was pressed out. There are 24 convex strips with a height of 2mm that are aligned with the length direction of the support body and arranged side by side at intervals evenly distributed on the lower surface (the cross section of the convex strips is as follows: figure 2 The square shown in b, the width of the bottom is 1mm, and the chamfering arc of the joint between the raised strip and the support body is π / 6); ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com