A kind of electrode material for solid-state lithium-sulfur battery at room temperature and its preparation method and solid-state lithium-sulfur battery

An electrode material, lithium-sulfur battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as reducing electrochemical reaction kinetics, increasing local stress/strain and interface resistance, and improving electrochemical reaction kinetics. The effect of improving electrochemical performance and long cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The present invention also provides a preparation method of the electrode material for the above-mentioned solid-state lithium-sulfur battery, comprising the following steps:

[0031] A) ball milling the transition metal sulfide and sulfur to obtain the mixture;

[0032] B) reacting the mixture under high temperature and high pressure conditions to obtain an electrode material for a solid lithium-sulfur battery.

[0033] In the present invention, the transition metal sulfide and sulfur are firstly mixed, and the present invention has no special limitation on the mixing method of the two, and manual grinding and mixing are preferred. Next, ball milling is performed. Wherein, the rotational speed of the ball mill is 100-400 rpm, preferably 200-300 rpm; the time is 1-36 h, preferably 2-30 h.

[0034] The mass ratio of the transition metal sulfide to sulfur is (0.01-10):(0.01-10), preferably (0.1-1):(0.1-1).

[0035] After the mixture is obtained, the mixture is reacted ...

Embodiment 1

[0045] 4 mmol FeSO 4 ·7H 2 O was added to 40 mL of N,N-dimethylformamide and 30 mL of ethylene glycol mixed solvent, stirred at room temperature for 1.0 h until completely dissolved, and a mixed solution was obtained; then 40 mmol of urea was added to the above mixed solvent and stirred magnetically for a period of time. Finally, under the protection of argon atmosphere, 20 mmol of sublimed sulfur was added therein, and reacted in a three-necked flask at 180° C. for 8 h. The black precipitate was washed by centrifugation and freeze-dried for 24 hours to obtain iron disulfide.

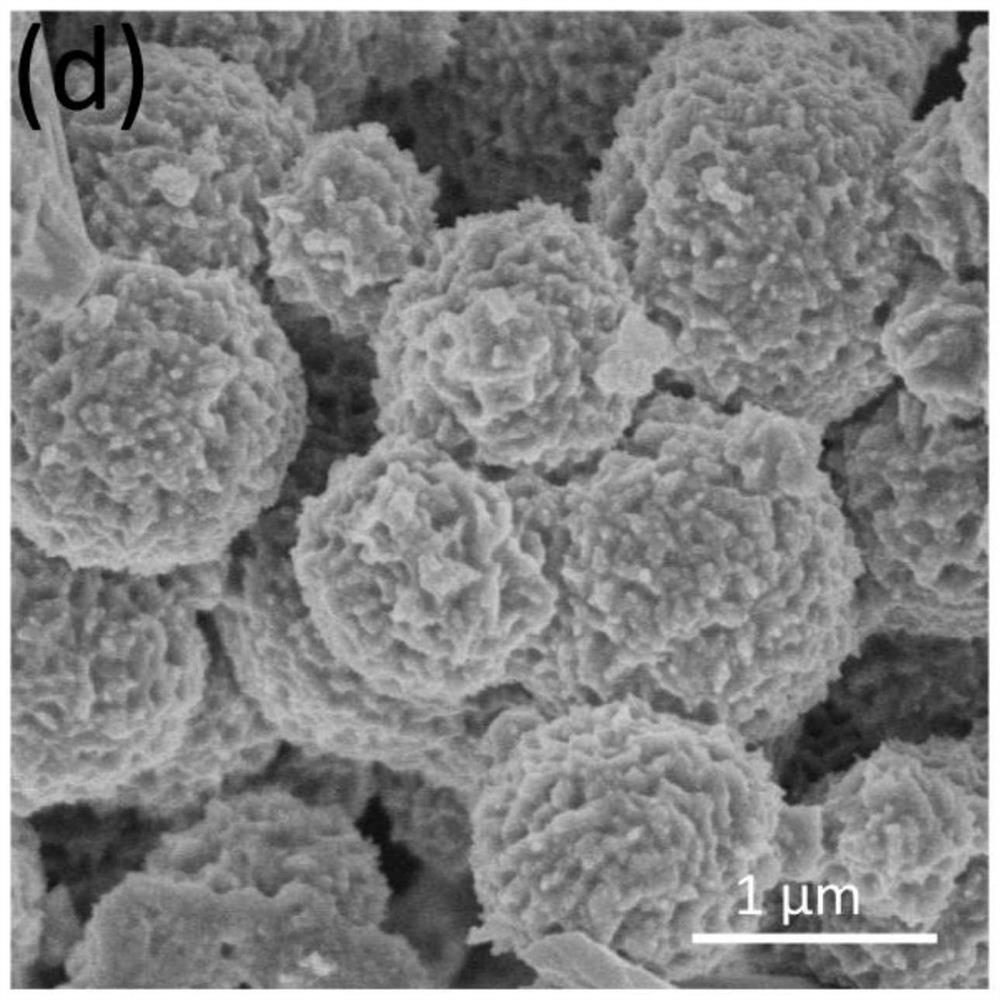

[0046] It is determined that the size of the iron disulfide is 100 nm-10 μm, and its microscopic appearance is spherical.

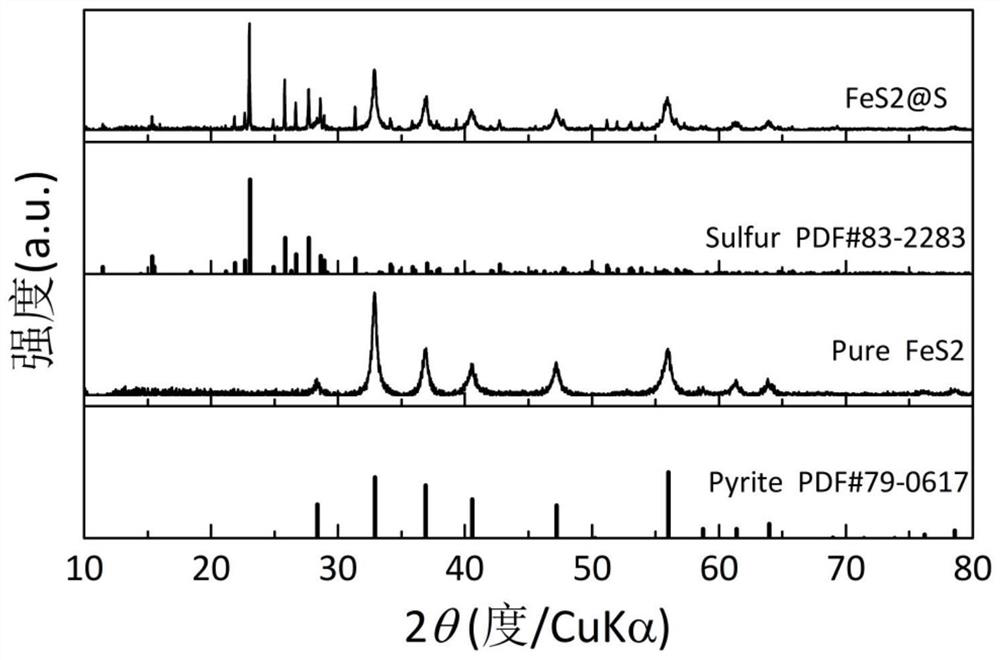

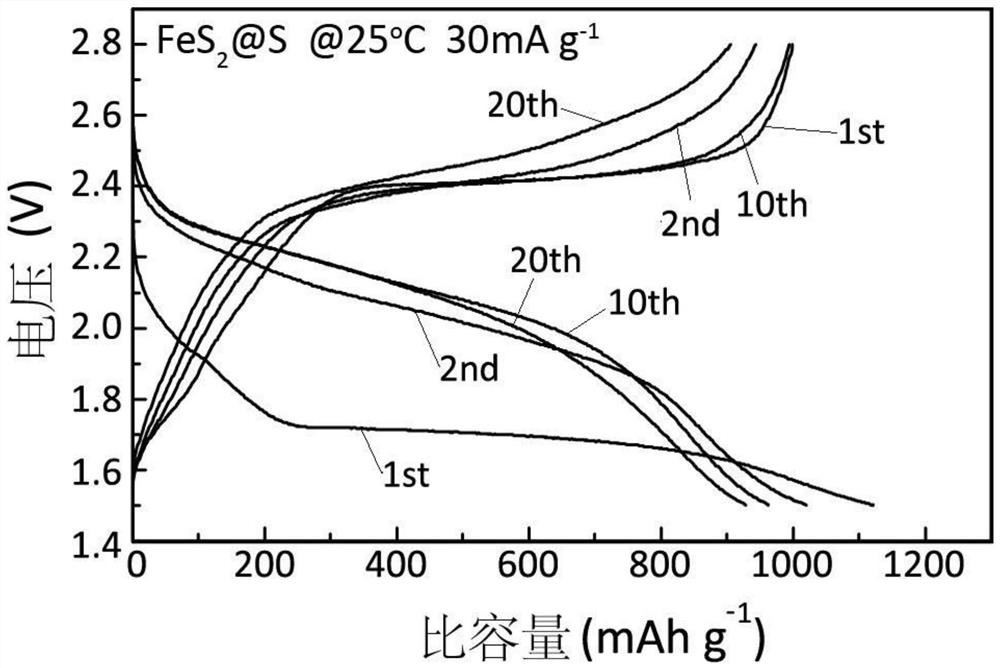

[0047] Then 100 mg of iron disulfide and 100 mg of elemental sulfur were manually ground and mixed, then ball milled and mixed at a speed of 500 rpm for 12 hours, and then reacted at 155° C. for 12 hours to obtain a composite electrode material of iron disulfide and elemental sul...

Embodiment 2

[0053] 1g Na 3 VO 4 Completely dissolve in 70mL of deionized water, stir magnetically for 2h, add 2g of thioacetamide and continue stirring until completely dissolved. Then transfer to a 100mL hydrothermal reaction kettle to react at 160°C for 24h, finally centrifuge washing, and freeze-drying to obtain vanadium tetrasulfide.

[0054] It is determined that the size of the vanadium tetrasulfide is 100 nm to 10 μm, and its microscopic appearance is spherical.

[0055] Then 100 mg of vanadium tetrasulfide and 100 mg of sublimed sulfur were manually ground and mixed, then ball milled and mixed for 12 hours at a speed of 500 rpm, and then reacted at 155 °C for 12 hours under airtight conditions to obtain a composite of vanadium tetrasulfide and elemental sulfur electrode material.

[0056] The electrode material prepared above was mixed with Li 10 GeP 2 S 12 The solid electrolyte and super P were manually ground for 0.5h according to the mass ratio of 45:50:5 to prepare the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com