Preparation method of methane reforming reaction catalyst

A reforming reaction and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, inorganic chemistry, etc., can solve the problems of activated carbon pore collapse, easy consumption of surface functional groups, affecting the catalytic life of catalysts, etc., to reduce the reaction temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

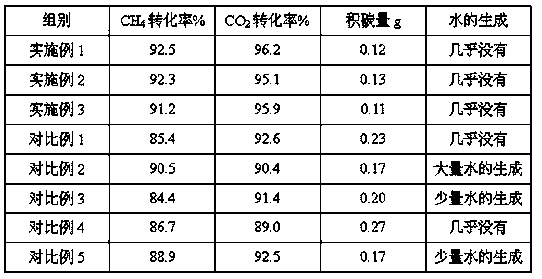

Embodiment 1

[0022] Embodiment 1 A kind of preparation method of methane reforming reaction catalyst

[0023] Follow these steps:

[0024] (1) Mix and stir 25 parts of activated carbon powder, 0.8 part of titanium dioxide powder, 6 parts of hexamethyldisilazane, 1.5 parts of dispersant and 1.5 parts of polystyrene in parts by weight for 10 minutes to obtain a mixed reagent; the dispersant It is composed of polyammonium methacrylate and polyethylene glycol-6000 in a weight ratio of 1:2;

[0025] (2) Mix the mixed reagent obtained in step (1) with expanded perlite (30:1 by weight), and ball mill at 75°C for 40 hours to obtain a black slurry;

[0026] (3) Sublimate and dry the black slurry obtained in step (2) at a temperature of -35°C and 0.25 atmospheres for 110 hours, pulverize, and then pass ammonia gas at a temperature of 800°C with a flow rate of 30ml / min and roast for 6 hours , cooled to obtain a light solid;

[0027] (4) Dissolve the light solid matter obtained in step (3) in water...

Embodiment 2

[0028] Embodiment 2 A kind of preparation method of methane reforming reaction catalyst

[0029] Follow these steps:

[0030] (1) Mix and stir 20 parts of activated carbon powder, 0.5 part of titanium dioxide powder, 7 parts of hexamethyldisilazane, 1 part of dispersant and 2 parts of polystyrene in parts by weight for 8 minutes to obtain a mixed reagent; the dispersant It is composed of polyammonium methacrylate and polyethylene glycol-6000 in a weight ratio of 1:1;

[0031] (2) Mix the mixed reagent obtained in step (1) with expanded perlite (weight ratio: 20:1), and ball mill at 90°C for 30 hours to obtain a black slurry;

[0032] (3) Sublimate and dry the black slurry obtained in step (2) for 120 hours at a temperature of -30°C and 0.1 atmospheric pressure, and pulverize it, then pass through ammonia gas at a temperature of 700°C with a flow rate of 40ml / min, and roast for 4 hours , cooled to obtain a light solid;

[0033] (4) Dissolve the light solid matter obtained in...

Embodiment 3

[0034] Embodiment 3 A kind of preparation method of methane reforming reaction catalyst

[0035] Follow these steps:

[0036] (1) Mix and stir 30 parts of activated carbon powder, 1 part of titanium dioxide powder, 5 parts of hexamethyldisilazane, 2 parts of dispersant and 1 part of polystyrene in parts by weight for 12 minutes to obtain a mixed reagent; the dispersant It is composed of polyammonium methacrylate and polyethylene glycol-6000 in a weight ratio of 1:3;

[0037] (2) Mix the mixed reagent obtained in step (1) with expanded perlite (40:1 by weight), and ball mill at 60°C for 50 hours to obtain a black slurry;

[0038] (3) The black slurry obtained in step (2) was sublimed and dried for 90 hours at a temperature of -40°C and 0.4 atmospheric pressure, and pulverized, and then passed through ammonia gas at a temperature of 900°C, with a flow rate of 20ml / min, and roasted for 8 hours , cooled to obtain a light solid;

[0039] (4) Dissolve the light solid matter obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com