High electron mobility transistor with coupling field plates

A high electron mobility, transistor technology, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of uneven lateral electric field distribution, large lateral electric field front value of the source field plate, and low lateral voltage withstand capability of the device. Achieve the effects of optimized electric field distribution, low lateral withstand voltage capability, and fast switching speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

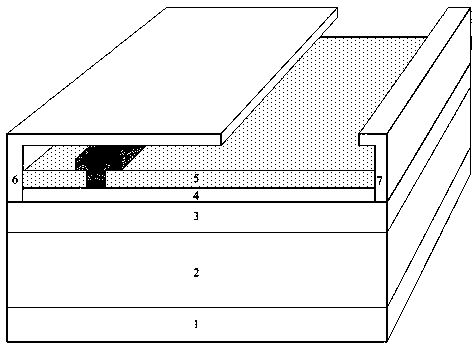

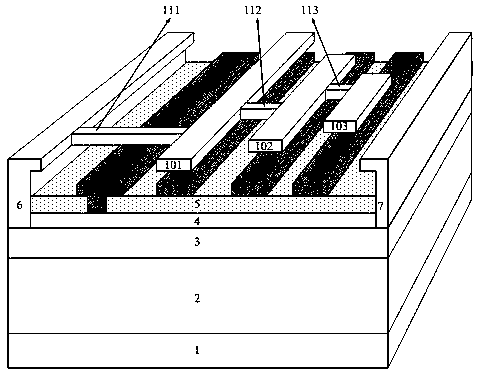

[0023] The invention discloses a high electron mobility transistor with a coupling field plate, comprising: a substrate 1; a buffer layer 2 is arranged above the substrate 1; a channel layer 3 is arranged above the buffer layer 2; and a channel layer 3 is arranged above the channel layer 3 A source electrode 6, a drain electrode 7 and a barrier layer 4 are provided, and the source electrode 6 and the drain electrode 7 are located at both ends of the barrier layer 4, and the barrier layer 4 is located in the middle of the source electrode 6 and the drain electrode 7; the barrier layer 4, a dielectric layer 5 and a gate electrode 8 are arranged above; it is characterized in that several coupling field plates are arranged on the surface of the dielectric layer 5 between the gate electrode 8 and the drain electrode 7, and all coupling field plates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com