Photoelectric hybrid cable with high tensile strength and capable of monitoring water seepage

An optoelectronic hybrid cable and tensile force technology, applied in power cables, power cables including optical transmission elements, insulated cables, etc., can solve problems such as increased cost, inability to transmit electrical signals, increased damage, etc., to improve high temperature resistance. , the effect of strong tensile resistance and strong lateral pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

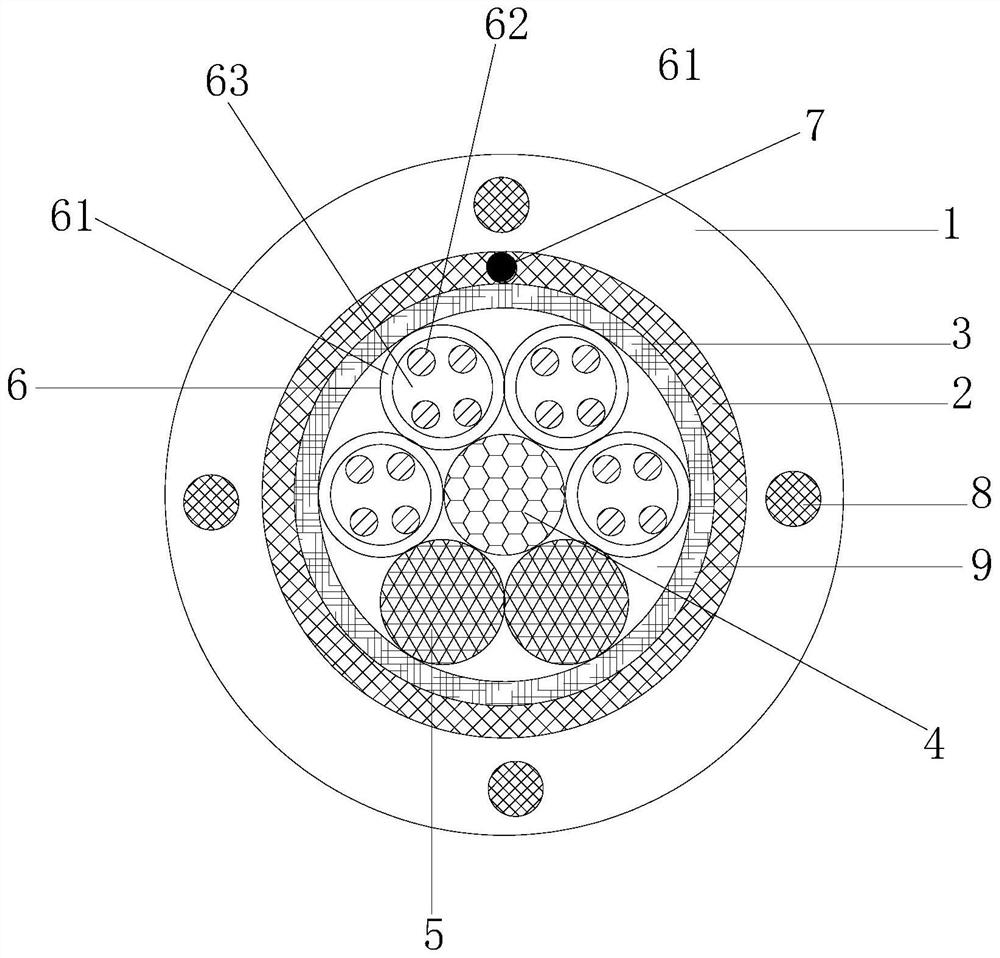

[0021] Such as figure 1 Shown is a preferred embodiment of a photoelectric hybrid cable with high tensile strength and capable of monitoring water seepage. The photoelectric hybrid cable includes an outer sheath 1 arranged from outside to inside, a water-absorbing resin layer 2, a wrapping layer 3 and Cable core; the central position of the cable core is provided with a central reinforcement 4, the central reinforcement 4 is made of thermoplastic resin and glass fiber mixed material, and the cable core also includes a filling rope 5 arranged around the central reinforcement 4 and a plurality of optical fiber cables 6; in this embodiment, the numb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com