A method for retaining entry along the gob with mesh cage filling and support at the entryway

A technology of empty entry retaining and mesh cage, which is applied in the direction of filling, earth square drilling, mining equipment, etc., can solve the problems of low degree of mechanization, failure of entry retaining, cracking of walls, etc., and achieve high strength and shrinkage, The effect of improving coal recovery rate and strong lateral pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

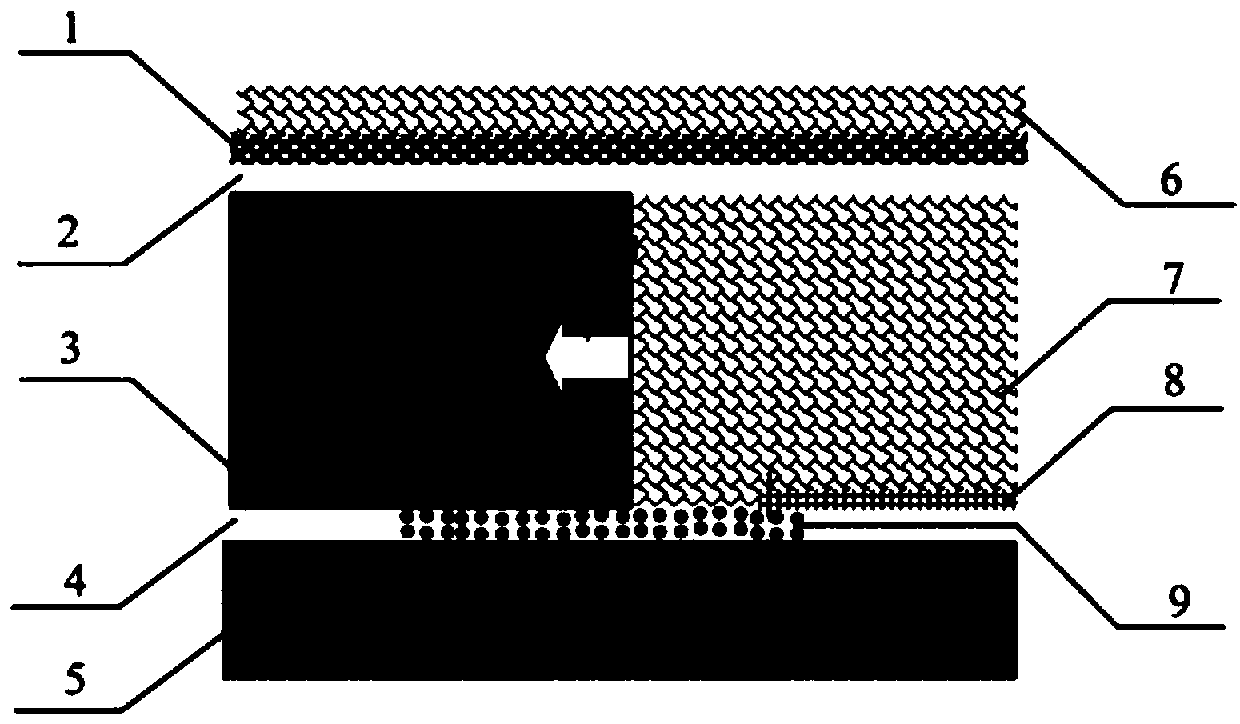

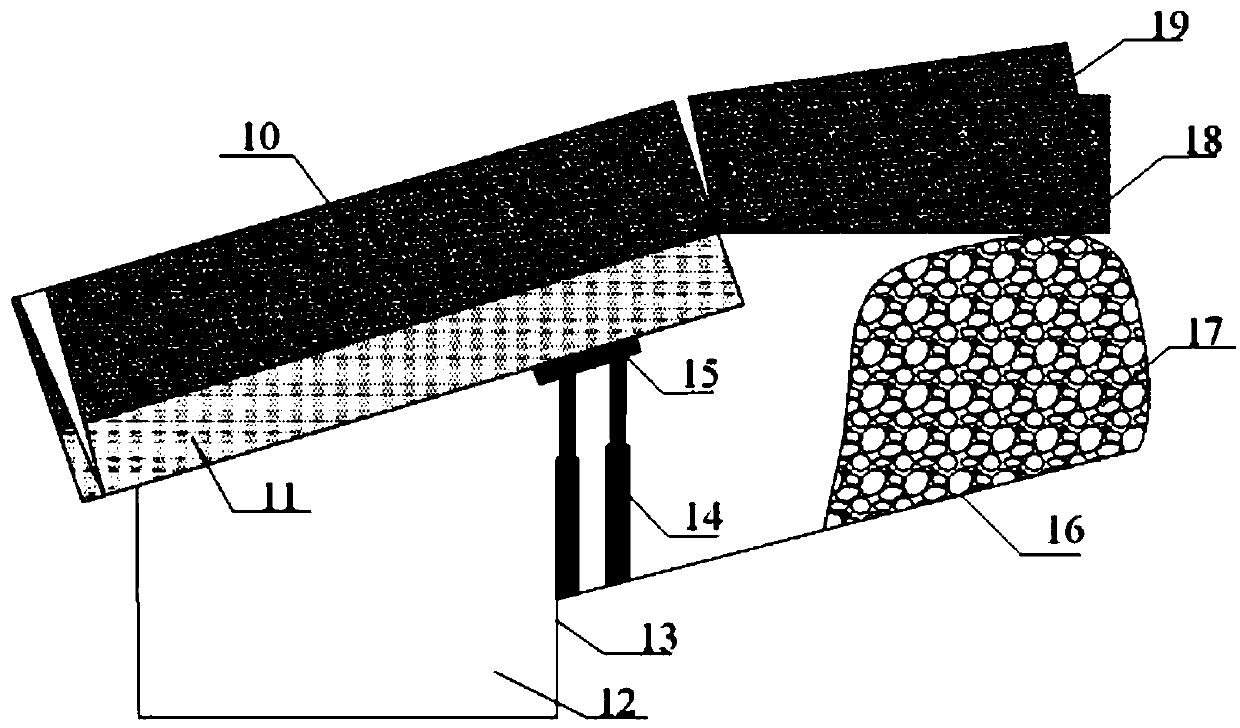

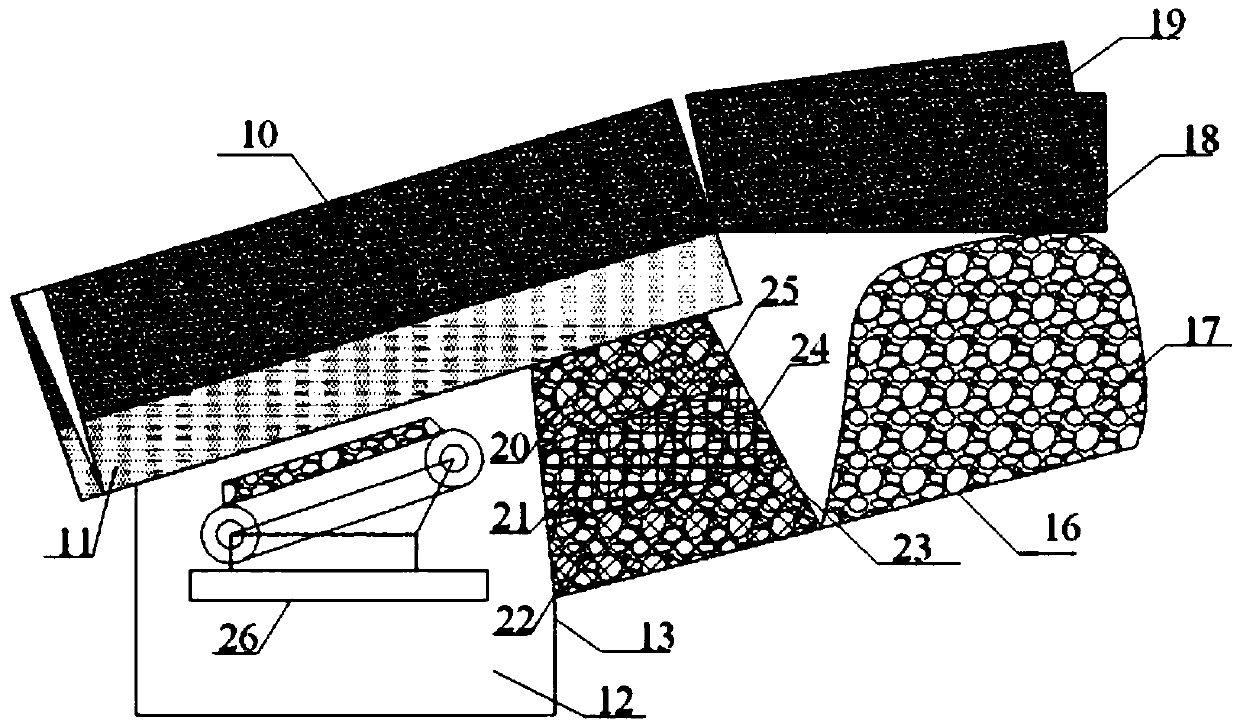

[0011] The specific implementation method of gob-side entry retention (taking three floors as an example) of the present invention is as follows:

[0012] 1. Obtain the impact of different particle sizes and lateral support stress on its bearing capacity through the rigid and flexible constraint gangue body test; determine the first layer of gangue (13), the second layer of gangue (12) and the third layer of filling The particle size of the gangue (11) is such that the upper layer of gangue has sufficient shrinkage to achieve the purpose of yielding, and the lower layer of gangue has a greater strength to meet the needs of supporting strength.

[0013] 2. Put two single hydraulic props (5) on the upper side (4) with hinged roof beams (6) for support (also can be supported by fully mechanized mining supports). The single hydraulic prop (5) has sufficient initial support force and large shrinkable amount, so that the sinking amount of the top plate can be effectively controlled....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com