Electro-optic compound cable for towing and manufacturing method thereof

A technology of optoelectronic composite cable and production method, which is applied in the direction of cable/conductor manufacturing, insulated cable, communication cable, etc., can solve the problems of difficult deployment, inability to meet repeated retractable use, inconvenient construction and use, etc., and achieves the production process flow Reliable, guaranteed wear resistance, lightweight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

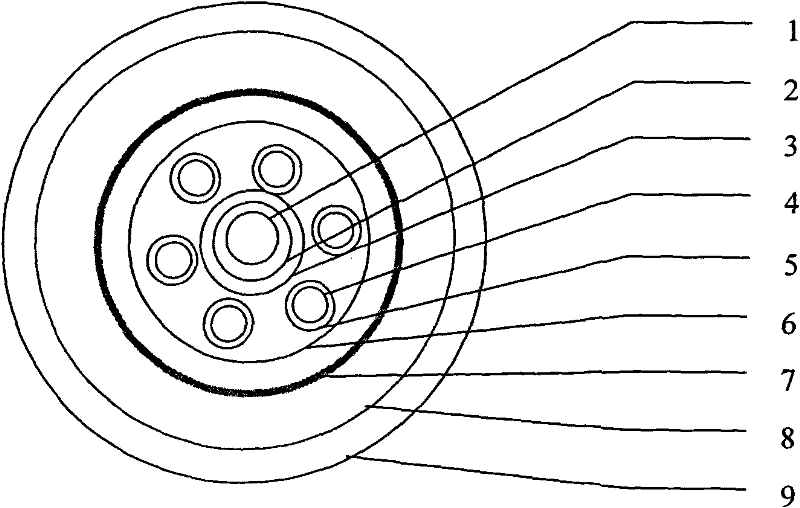

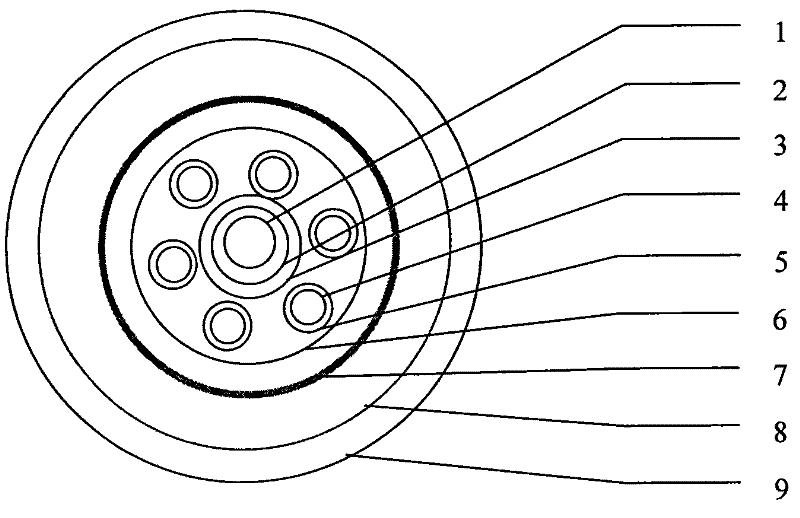

[0021] Refer to attached figure 1 , a photoelectric composite cable for towing is composed of multiple silver-plated conductors 4, tight-buffered optical fibers, polyester tape 6, spiral stainless steel hose 7, aramid twisted layer 8, and polyurethane sheath 9. The tight-buffered optical fiber is coated with a layer of silicone rubber buffer layer 2 on the optical fiber 1, and a layer of tight-buffered layer 3 of nylon material is arranged outside the silicone rubber buffer layer. High-temperature fluoroplastics are extruded outside the silver-plated wire 4 as the insulating sheath 5 . The tight-buffered optical fiber is placed in the center of the silver-plated wire 4, thus forming the core of the photoelectric composite cable—the cable core. The tight-buffered optical fiber and the silver-plated wire 4 are twisted into a cable core in the form of S twisting, and the polyester tape 6 is used to bind The cable core is wrapped and fixed, a spiral stainless steel hose 7 is arra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| service temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com