Novel method for testing zinc chloride in potassium chloride galvanization solution

A technology of potassium chloride and zinc chloride, applied in the direction of chemical analysis by titration, can solve problems such as the interference of zinc chloride measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Draw 2 mL of potassium chloride galvanizing solution to be tested into a 300 mL conical flask, add 50 mL of water to dilute, add 0.5 g of sodium fluoride, 0.3 g of ascorbic acid, 10 mL of ammonia-ammonium chloride buffer solution, and sodium dimethyldithiocarbamate Solution 10mL, add a little chrome black T indicator, after shaking well, the test solution turns purple, then titrate with EDTA standard solution until the test solution turns blue as the end point.

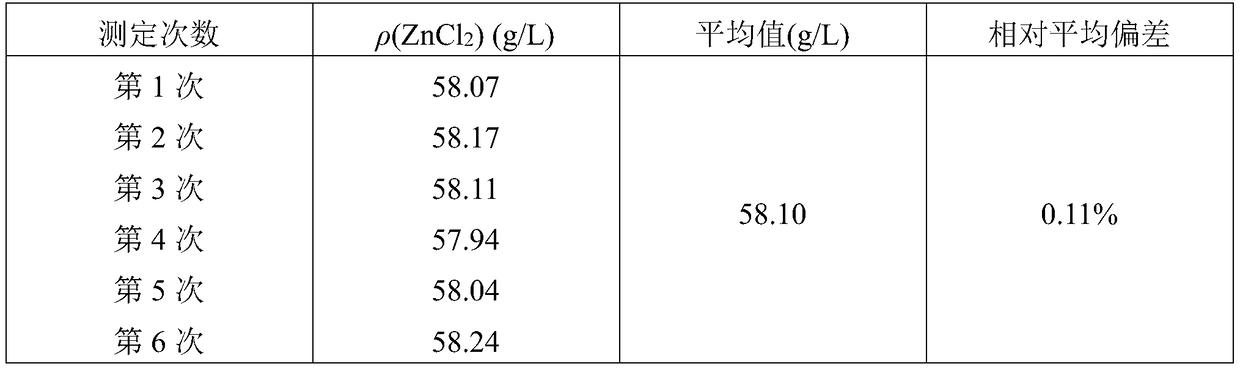

[0037] Calculate the mass concentration of zinc chloride in the potassium chloride galvanizing solution, and the calculation formula is: ρ(ZnCl 2 ) = 136.3cV / V 0 ; Among them, ρ(ZnCl 2 ) represents the mass concentration (g / L) of zinc chloride, 136.3 is the molar mass (g / mol) of zinc chloride, c is the amount concentration (mol / L) of the substance of EDTA standard solution, V is the consumption of EDTA standard solution Volume (mL), V 0 is the volume (mL) drawn of the potassium chloride galvanizing solution ...

Embodiment 2

[0042] Take 2 mL of potassium chloride zinc plating solution and place it in a 300 mL conical flask, add 70 mL of water to dilute, add 1 g of sodium fluoride, 0.4 g of ascorbic acid, 10 mL of ammonia-ammonium chloride buffer solution, and 10 mL of sodium dimethyldithiocarbamate solution, Add a little chrome black T indicator, and titrate with EDTA standard solution until the test solution changes from purple red to blue as the end point.

[0043] Calculate the mass concentration of zinc chloride in the potassium chloride galvanizing solution, and the calculation formula is: ρ(ZnCl 2 ) = 136.3cV / V 0 ; Among them, ρ(ZnCl 2 ) represents the mass concentration (g / L) of zinc chloride, 136.3 is the molar mass (g / mol) of zinc chloride, c is the amount concentration (mol / L) of the substance of EDTA standard solution, V is the consumption of EDTA standard solution Volume (mL), V 0 is the volume (mL) of the potassium chloride galvanizing solution absorbed.

[0044]Determine the mass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com