A single-component waterproof coating film for pasting ceramic tiles and its preparation method

A waterproof coating film, one-component technology, applied in antifouling/underwater coatings, coatings, paints containing biocides, etc., can solve the problems of complex process, waterproof damage, economic losses, etc. Good water resistance, low water absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

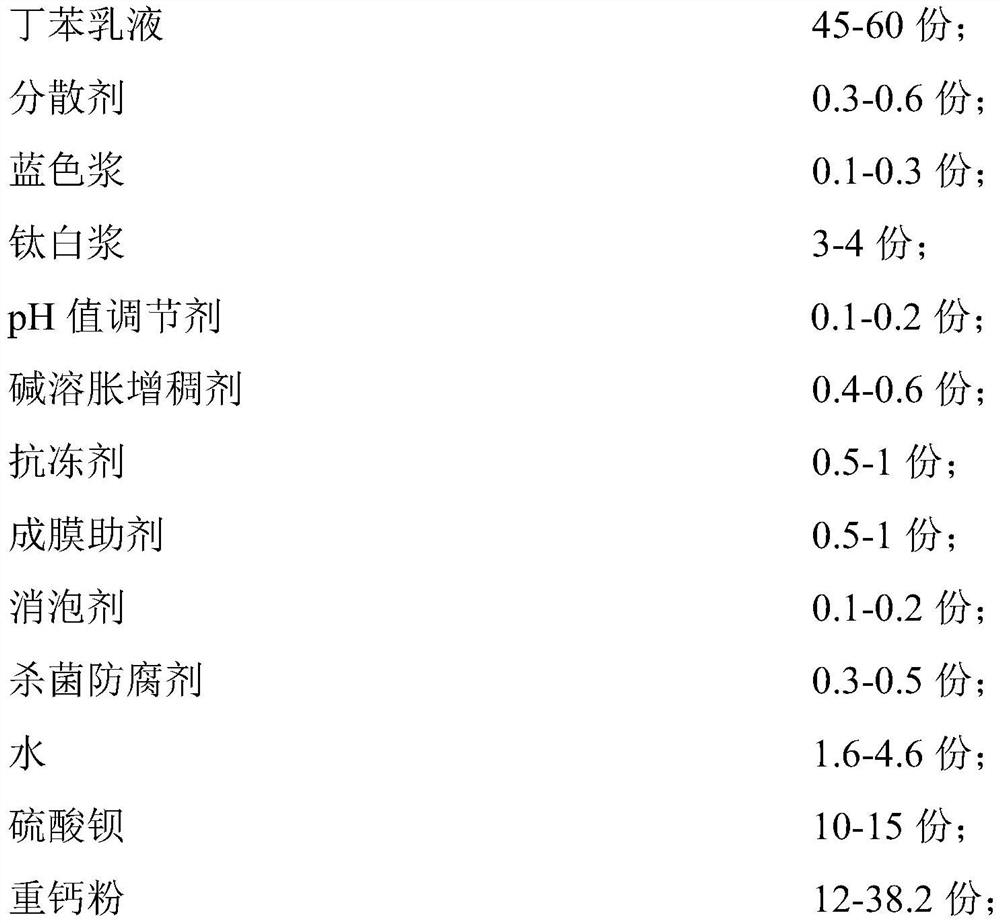

[0036] Single component waterproof coating for a ceramic tile adhesive, the following components:

[0037]

[0038] The single-component water-resistant coating paste for ceramic tiles, which is prepared as follows:

[0039] (1) Start Dispersing machine: adding to the dispersion tank 50 parts of latex, while stirring while adding 0.3 parts of a dispersant, 0.3 parts of blue syrup, 0.1 parts of a defoaming agent, thoroughly stirred and mixed colloidal mixture formed, mixing the speed control 300 ~ 500rpm;

[0040] (2) grinding and dispersion: Add 3 parts of titanium white dispersion slurry tank, 30.7 parts by weight of calcium powder, 10 parts of barium sulfate, controlling the rotational speed of less than 50um in 1500 2500rpm milled to a fineness of under beating ~ 20 to 25 minutes;

[0041] (3) adding additives: 0.8 parts of antifreeze agent, 0.7 parts of film-forming aid, 0.5 parts antiseptic and 0.75 parts of water, pre-mixed with stirring in the dispersing tank is added wit...

Embodiment 2

[0045] Single component waterproof coating for a ceramic tile adhesive, the following components:

[0046]

[0047] The single-component water-resistant coating paste for ceramic tiles, which is prepared as follows:

[0048] (1) Start Dispersing machine: adding to the dispersion tank 45 parts of latex, while stirring while adding 0.5 parts of a dispersant, 0.2 parts of blue syrup, 0.2 parts of a defoaming agent, thoroughly stirred and mixed colloidal mixture formed, mixing the speed control 300 ~ 500rpm;

[0049] (2) grinding and dispersion: 3.5 parts of titanium white slurry was added in the dispersion tank, 34.5 parts by weight of calcium powder, 12 parts of barium sulfate, controlling the rotational speed of less than 50um in 1500 2500rpm milled to a fineness of under beating ~ 20 to 25 minutes;

[0050] (3) adding additives: 0.5 parts of antifreeze agent, 0.5 parts of film-forming aid, 0.3 parts antiseptic and 0.5 parts of water pre-mixed, stirred tank in the dispersion is a...

Embodiment 3

[0054] Single component waterproof coating for a ceramic tile adhesive, the following components:

[0055]

[0056] The single-component water-resistant coating paste for ceramic tiles, which is prepared as follows:

[0057] (1) Start Dispersing machine: adding to the dispersion tank 55 parts of latex, was added while stirring while 0.6 parts of a dispersant, 0.1 parts of blue syrup, 0.2 parts of a defoaming agent, thoroughly stirred and mixed colloidal mixture formed, mixing the speed control 300 ~ 500rpm;

[0058] (2) grinding and dispersion: 4 parts of titanium white slurry was added in the dispersion tank, 20.9 parts by weight of calcium powder, 15 parts of barium sulfate, to control the rotational speed 1500 2500rpm grinding fineness of the beating 20 to 25 minutes to less than 50um;

[0059] (3) adding additives: 0.7 parts of antifreeze agent, 0.95 parts of film-forming aid, 0.4 parts of water 0.4 parts antiseptic and pre-mixed with stirring in the dispersing tank is added...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com