Low-temperature fur dyeing aid as well as preparation method and application thereof

A low-temperature dyeing and fur technology, applied in the field of dyeing technology, can solve the problems of easy shrinkage of leather and poor high temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

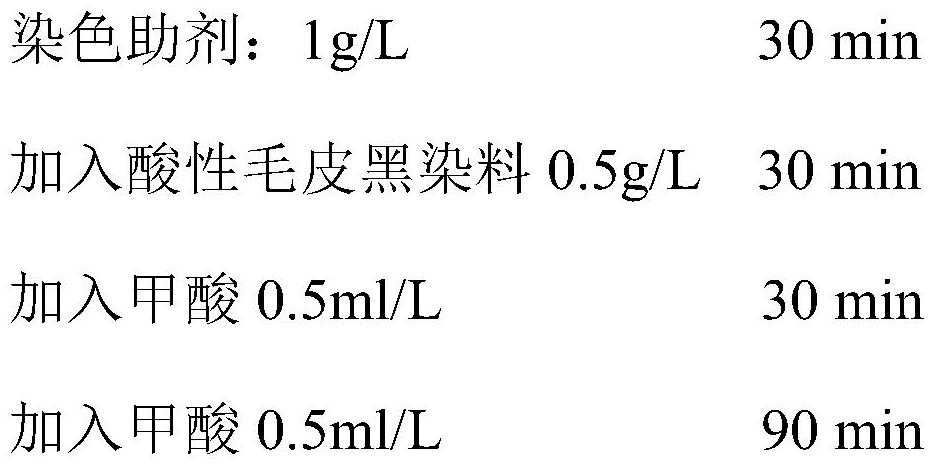

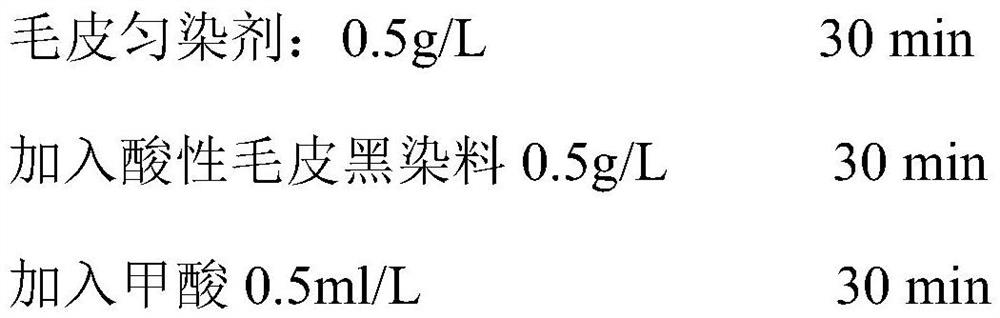

Method used

Image

Examples

Embodiment 1

[0040]The present embodiment provides a low-temperature fur dyeing auxiliary, which includes 2 parts of hair opener (triethanolamine), 5 parts of solubilizer (octadecyl polyoxyethylene ether alkyl ammonium chloride), osmotic Agent (isomeric tridecyl alcohol polyoxyethylene ether 1305) 6 parts, dispersant (fatty alcohol polyoxyethylene ether AEO15) 10 parts, stabilizer (dipropylene glycol methyl ether) 5 parts, deionized water 30 parts.

[0041] Its preparation method is:

[0042] (1) After heating deionized water to 50°C, mix with the above-mentioned hair opener, solubilizer, penetrant, dispersant, and stabilizer, and stir to dissolve all the raw materials;

[0043] (2) Cool down the mixed raw materials to 30° C., let stand for 4 hours, and discharge to obtain a light yellow transparent liquid product, which is the low-temperature dyeing auxiliaries for fur.

Embodiment 2

[0045] The present embodiment provides a low-temperature dyeing auxiliary for fur, which comprises 4 parts of a hair opener (diethylamine), 8 parts of a solubilizer (dodecyldimethylpropyl betaine), and a penetrating agent in parts by weight. (Isomerized tridecyl alcohol polyoxyethylene ether 1307) 10 parts, dispersant (fatty alcohol polyoxyethylene ether AEO22) 15 parts, stabilizer (diethylene glycol butyl ether) 8 parts, deionized water 55 parts.

[0046] Its preparation method is:

[0047] (1) After heating deionized water to 45°C, mix with the above-mentioned hair opener, solubilizer, penetrant, dispersant, and stabilizer, and stir to dissolve all the raw materials;

[0048] (2) Cool the mixed raw materials to 25° C., let stand for 3 hours, and discharge to obtain a light yellow transparent liquid product, which is the low-temperature dyeing auxiliaries for fur.

Embodiment 3

[0050] The present embodiment provides a fur low-temperature dyeing auxiliary, which includes 10 parts of a hair-opening agent (triethanolamine), 15 parts of a solubilizer (octadecyl polyoxyethylene ether alkyl ammonium chloride), osmotic Agent (isomeric tridecyl alcohol polyoxyethylene ether 1305) 15 parts, dispersant (fatty alcohol polyoxyethylene ether AEO15) 20 parts, stabilizer (dipropylene glycol methyl ether) 10 parts, deionized water 100 parts.

[0051] Its preparation method is:

[0052] (1) After heating deionized water to 50°C, mix with the above-mentioned hair opener, solubilizer, penetrant, dispersant, and stabilizer, and stir to dissolve all the raw materials;

[0053] (2) Cool down the mixed raw materials to 30° C., let stand for 4 hours, and discharge to obtain a light yellow transparent liquid product, which is the low-temperature dyeing auxiliaries for fur.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com