A kind of windproof and water-repellent machine-washable all-wool outdoor sports fabric and production method thereof

A production method and outdoor technology, applied in the textile field, can solve the problems of non-machine-washable all-wool fabrics and reduced windproof and water-repellent effects, and achieve the effect of high warp and weft yarn density, high breaking strength, and improved windproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

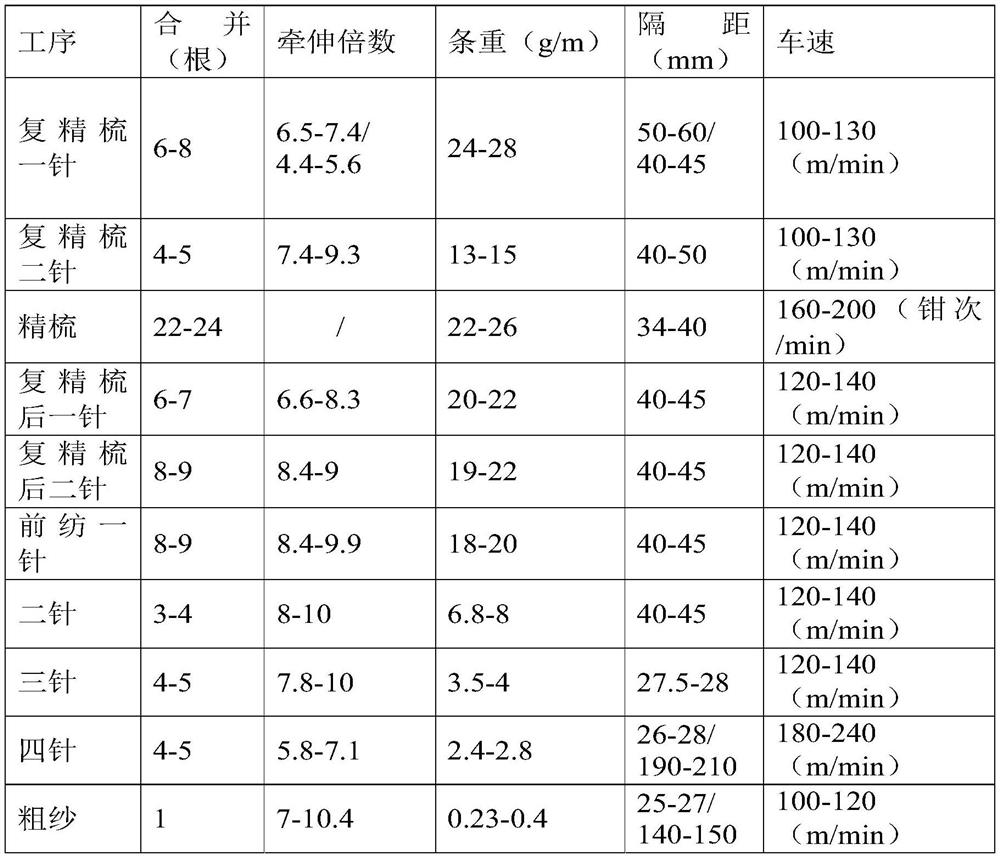

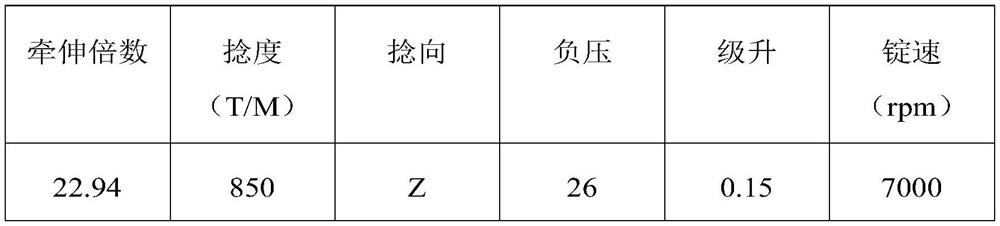

Embodiment 1

[0056] Shrinkable wool with a length of 110mm and a fineness of 14.5μm is used to make yarn through the spinning process, and then into gray fabric through the weaving process. The spinning process includes one needle of combing and two needles of combing in turn. , combing, one needle after double combing, two needles after double combing, one needle, two needles, three needles, four needles for pre-spinning, roving, spun yarn, winding, doubling, two-for-one twisting and shaping, pre-spinning process The parameters are as follows: in the one-needle combing process, the number of combined threads is 6, the draft ratio is 6.5 / 4.4, the sliver weight is 24g, the gauge is 60 / 45mm, and the speed is 100m / min; in the two-needle combing process, the combined The number of roots is 4, the drafting ratio is 7.4, the bar weight is 13g, the gauge is 40mm, and the speed is 100m / min; in the combing process, the number of combined roots is 22, the bar weight is 22g, the gauge is 34mm, and the...

Embodiment 2

[0059] Shrinkable wool with a length of 80mm and a fineness of 17.5μm is used to make yarn through the spinning process, and then into gray fabric through the weaving process. The spinning process includes combing one needle and combing two Needle, combing, one needle after double combing, two needles after double combing, one needle, two needles, three needles, four needles for pre-spinning, roving, spun yarn, winding, doubling, two-for-one twisting and setting, pre-spinning The parameters in the process are: in the one-needle combing process, the number of combined threads is 8, the draft ratio is 7.4 / 5.6, the sliver weight is 28g, the gauge is 60 / 45mm, and the speed is 130m / min; in the two-needle combing process, Combining root number 5, drafting ratio 9.3, bar weight 15g, gauge 50mm, speed 130m / min; in combing process, combined root number 24, bar weight 26g, gauge 40mm, speed 200 pincers / min; One needle after combing, number of combined roots 7, draft multiple 8.3, sliver...

Embodiment 3

[0062] Shrinkable wool with a length of 130mm and a fineness of 16μm is used to make yarn through the spinning process, and then into gray fabric through the weaving process. The spinning process includes one needle of combing and two needles of combing in turn. , combing, one needle after double combing, two needles after double combing, one needle, two needles, three needles, four needles for pre-spinning, roving, spun yarn, winding, doubling, two-for-one twisting and shaping, pre-spinning process The parameters are as follows: in the one-needle combing process, the number of combined threads is 8, the draft ratio is 7.4 / 5.6, the sliver weight is 28g, the gauge is 60 / 45mm, and the speed is 130m / min; in the two-needle combing process, the combined The number of roots is 5, the drafting ratio is 9.3, the bar weight is 15g, the gauge is 50mm, and the speed is 130m / min; in the combing process, the combined number of roots is 24, the bar weight is 26g, the gauge is 40mm, and the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com